Novel double-seal wear-resistant valve

A double-seal, wear-resistant valve technology, applied in the direction of shaft seal, sliding valve, valve details, etc., can solve the problems of valve wear, affecting the sealing performance of the gate, and not being able to discharge, etc., to achieve simple maintenance, good wear resistance, and use long life effect

Inactive Publication Date: 2012-10-03

杨猛

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Traditional gate valves often have scaling phenomenon, the valve is severely worn, which affects the sealing performance of the gate plate, and the slag cannot be discharged in the valve, which greatly affects the service life of the valve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

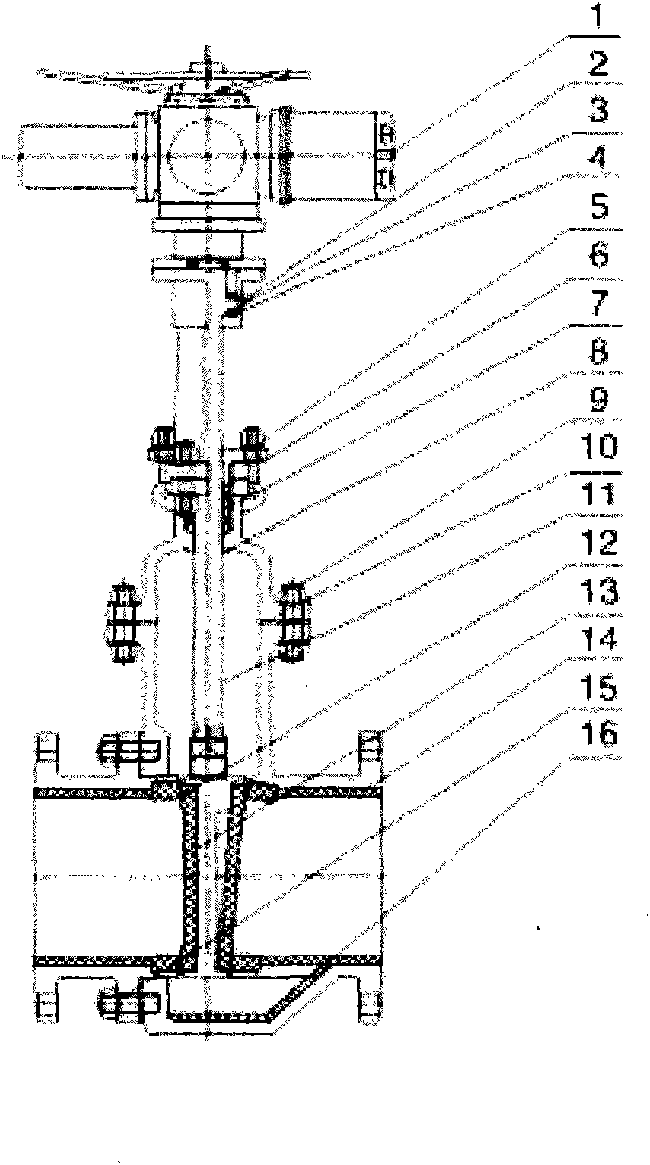

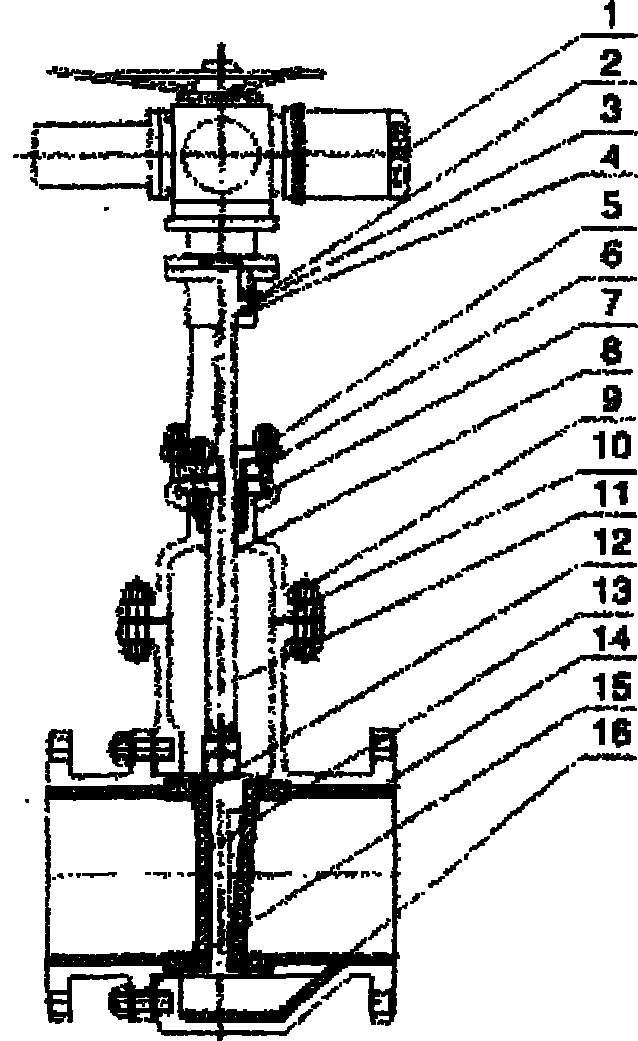

[0007] As shown in the figure, the new type of double-sealed wear-resistant valve is equipped with double seals, flexible graphite 7 is provided at the junction of the valve stem 11 and the valve body 15, and a hard seal 12 is provided at the gate 13. The double seal of flexible graphite 7 and hard seal 12 makes the valve have good sealing performance, and the valve has good corrosion resistance, scratch resistance and wear resistance.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of valves, in particular to a novel double-seal wear-resistant valve. The novel double-seal wear-resistant valve is characterized by comprising an electric device, an oil nozzle, a valve rod nut, a plane bearing, a cylinder, a filler pressing plate, flexible graphite, an upper seal, a screw, a composite gasket, a valve rod, a hard seal, a gate, a joint, a valve body and a bleed hole. The novel double-seal wear-resistant valve is provided with double seals, the flexible graphite is arranged at the joint of the valve rod and the valve body, and the hard seal is arranged at the gate, so that the valve has high corrosion resistance, high abrasion resistance and high wear resistance.

Description

Technical field [0001] The invention relates to the technical field of valves, in particular to a novel double-sealed wear-resistant valve. technical background [0002] Traditional gate valves often have fouling phenomenon, the valve is worn seriously, which affects the sealing performance of the gate, and the slag cannot be discharged in the valve, which greatly affects the service life of the valve. Summary of the invention [0003] In order to solve the above shortcomings, a new type of double-sealed wear-resistant valve with good sealing performance, corrosion resistance and long life is provided. The new type of double-sealed wear-resistant valve is characterized in that it includes: an electric device 1. an oil nozzle 2. Stem nut 3, plane bearing 4, cylinder 5, packing pressure plate 6, flexible graphite 7, upper seal 8, screw 9, composite gasket 10, valve stem 11, hard seal 12, gate 13, joint 14, valve Body 15, slag discharge port 16, the new type of double-sealed wear-re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16K3/30F16K41/02

Inventor 杨猛

Owner 杨猛

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com