Improved structure of oil pressure buffer

A technology of oil pressure buffer and internal pressure, applied in the direction of shock absorber, shock absorber, liquid shock absorber, etc., can solve the problems such as the force hindering the recovery and the uneven buffer effect, so as to reduce the maintenance amount and prolong the use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The specific embodiments of the present invention are only exemplary, and can only be used to explain the present invention rather than limit the present invention.

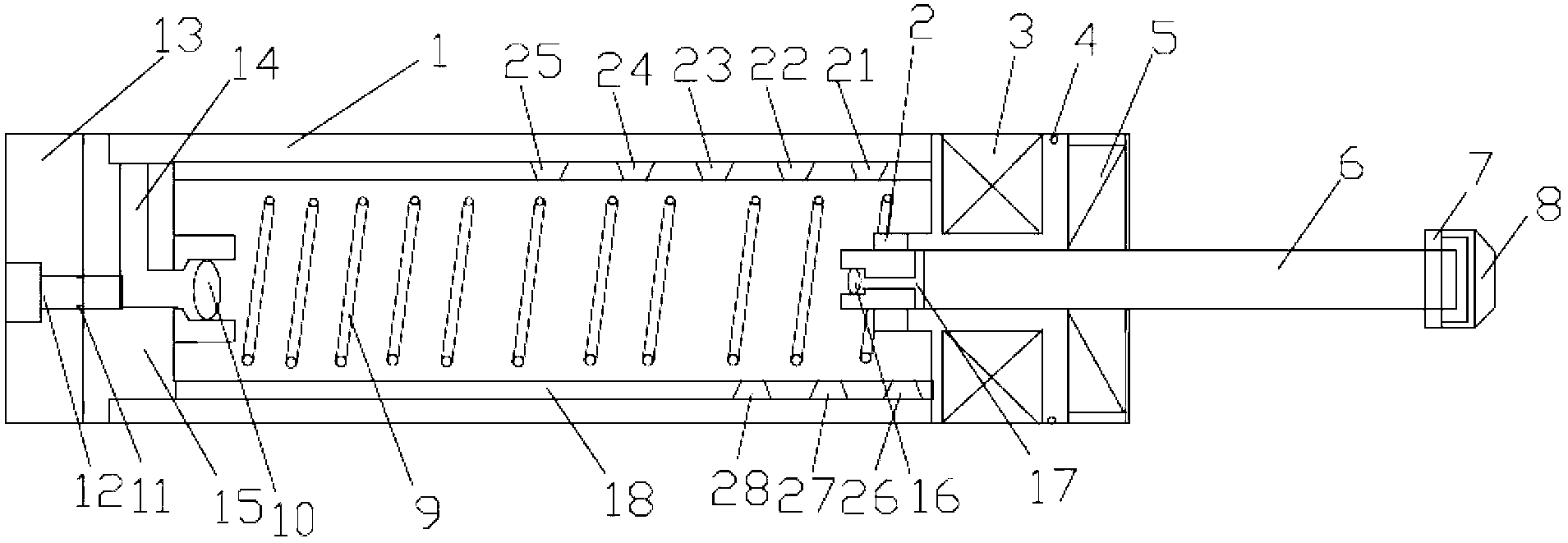

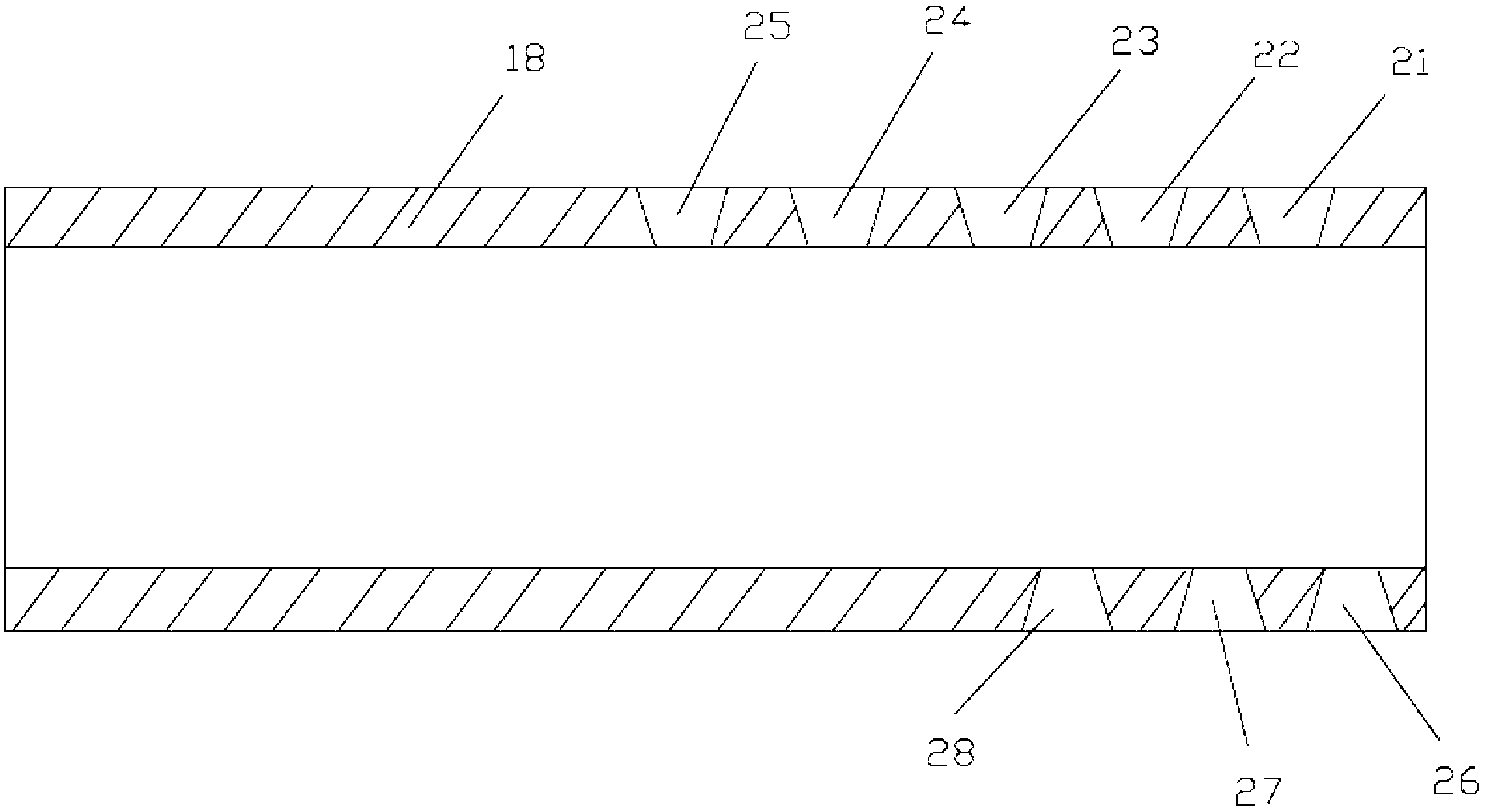

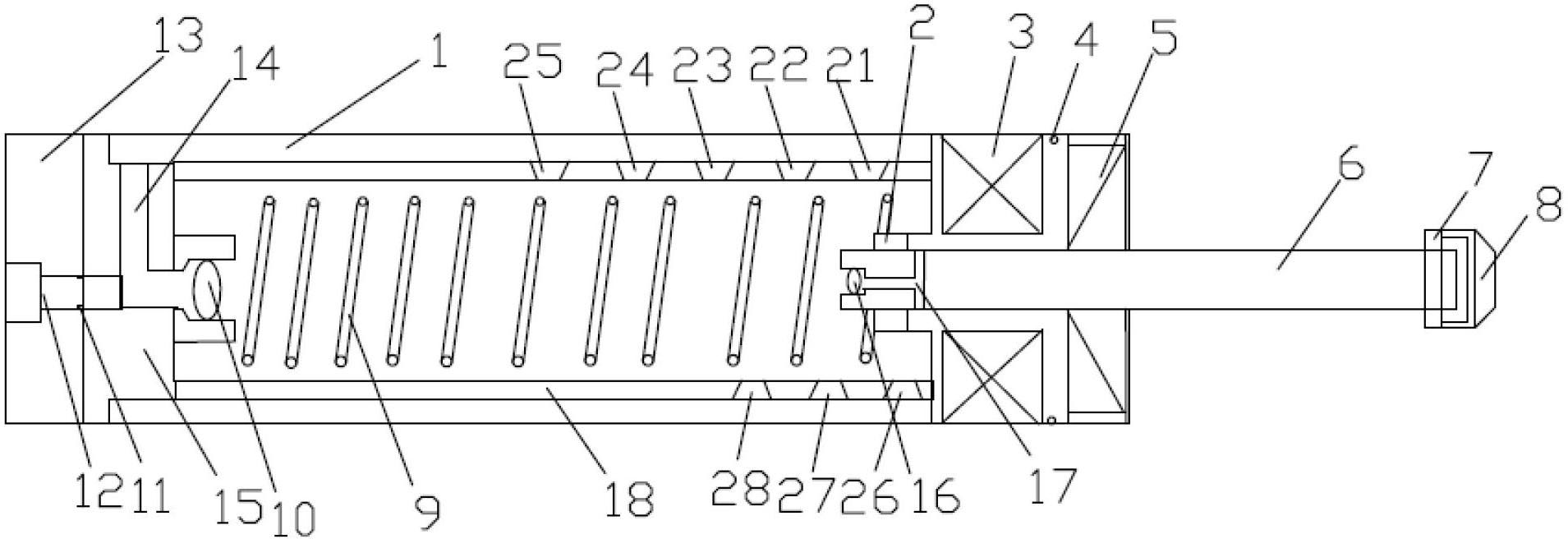

[0028] Such as Figure 1-Figure 2 Shown, the present invention is achieved through the following technical solutions:

[0029] An improved structure of an oil pressure buffer, including a housing 1, a rear cover 15, an oil seal 5, an internal pressure cylinder 18, a piston 2, a piston rod 6, an impact head 7, a bearing 4, a spring 9, a pressure accumulator 3, a flow rate Adjustment bolt 12 and flow adjustment knob 13; the end of piston rod 6 located in internal pressure cylinder 18 is provided with an oil storage chamber 17, and the oil storage chamber 17 is opened at the axis of the end of the piston rod. The pressure cylinder 18 communicates; the back cover 15 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com