Simple assembly method for miniature ball bearings

An assembly method and a technology of micro-balls, which are applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems affecting the assembly and use accuracy of bearings, difficult to clean Vaseline, and difficult to operate tweezers, so as to save work energy and improve assembly efficiency. Simple method and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

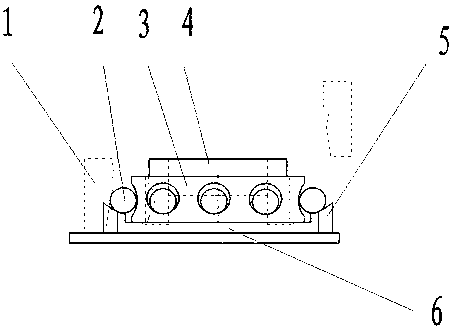

[0021] The present invention is a simple assembly method of a miniature ball bearing. The bearing assembled with the inner diameter of the inner ring not greater than 10 mm and the diameter 2r of the rolling ball not greater than 1.588 mm is called a miniature ball bearing, where r is the radius of the rolling ball , the assembly quantity of rolling balls matches the setting quantity of cage pockets, and the lubricating oil required for rolling balls in cage pockets has been given.

[0022] In order to clearly introduce the present invention, the outer ring 1, the cage 3 and the inner ring 4 in the miniature ball bearing are customized as follows, and these customizations will not be further explained in the following description.

[0023] Set the inner diameter reference of outer ring 1.

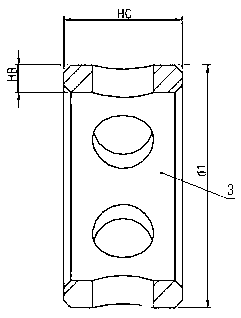

[0024] combine image 3 , The width of the cage 3 is represented by HC, the wall thickness of the cage 3 is represented by HB, and the outer diameter of the cage 3 is represented by d1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com