Independent oil supply sliding bearing with changeable pads and compressor equipped with bearing

A sliding bearing and pad technology, which is applied to the fields of oil-supplied sliding bearings with replaceable pads and compressors installed with the bearings, can solve the problems of high pad temperature, rising bearing pad temperature, waste of bearing body, etc. , to achieve the effect of large operating elastic range, reducing processing accuracy and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The specific embodiments described here are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

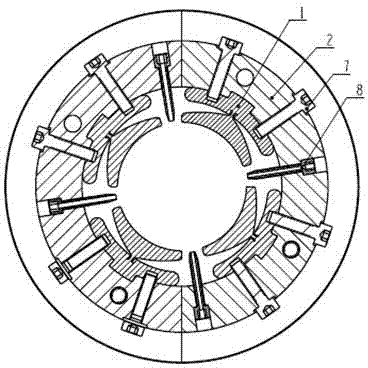

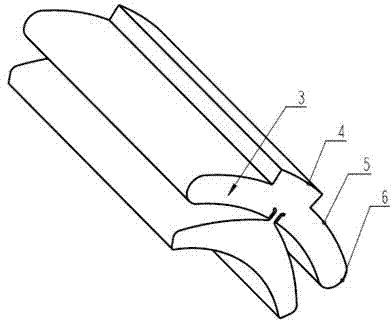

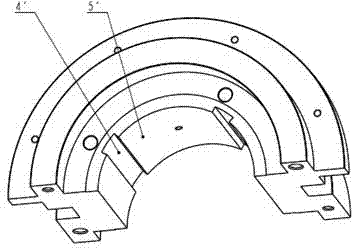

[0030] combined reference Figure 1 to Figure 4 As shown, an oil-supply sliding bearing for replaceable pads provided according to the present invention, in a specific embodiment, includes a concentric bearing body 2 and a pad 1, and the bearing body 2 has several recesses The inner contact surface 5' of the groove 4', the tile 1 has an outer arc-shaped plate 3, and the outer arc-shaped plate 3 has an outer contact surface 5 in seamless contact with the inner contact surface 5', and the outer The contact surface 5 is provided with a boss 4 that is interference fit with the groove 4', and the center line of the inner side of the outer arc plate 3 is fixedly connected with an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com