Method for starting variable frequency compressor

A variable frequency compressor and frequency technology, which is applied in the direction of machines/engines, liquid variable capacity machines, mechanical equipment, etc., can solve problems such as wear and tear, and achieve the effects of avoiding pipeline resonance, reducing wear, and avoiding quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

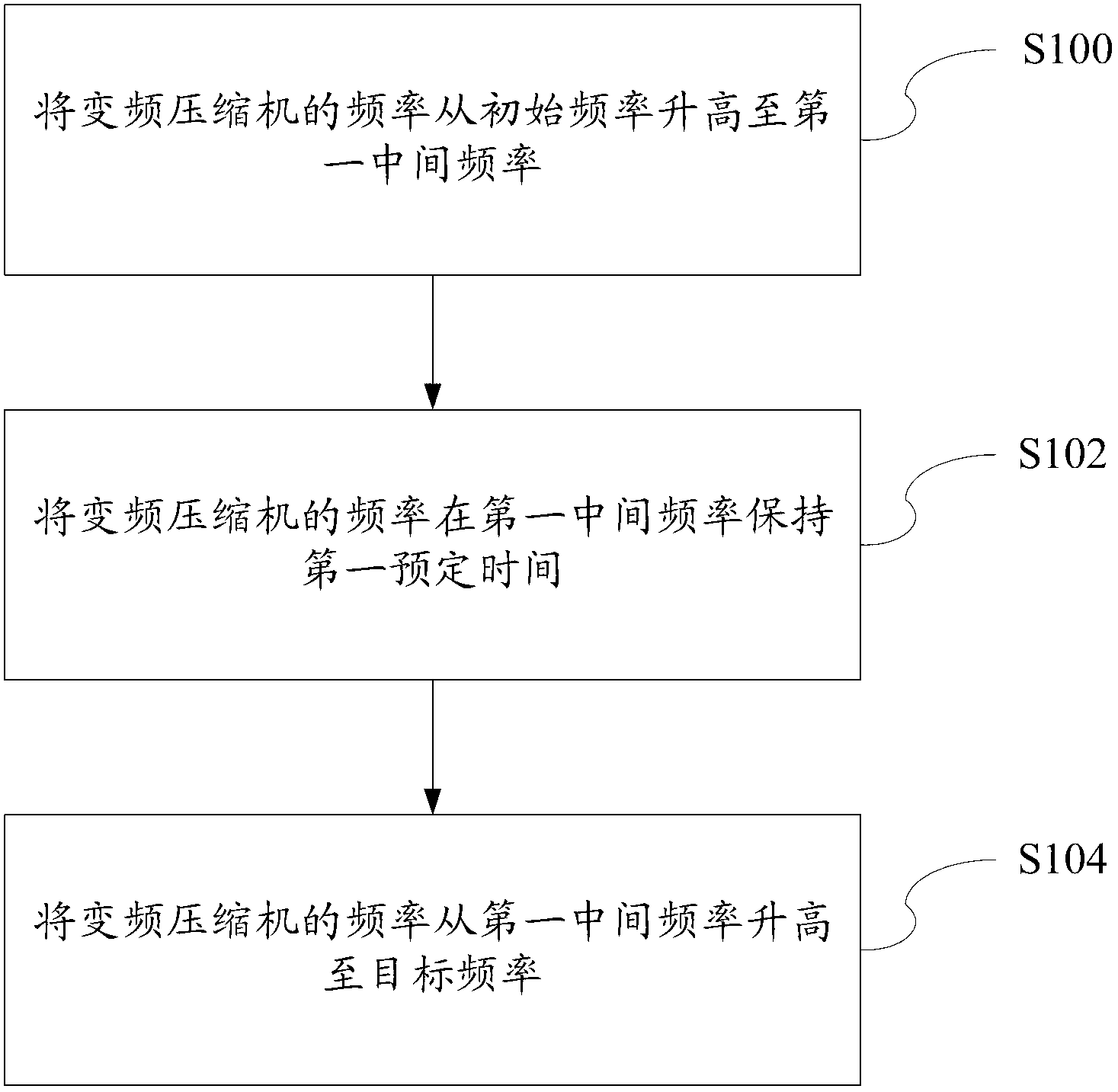

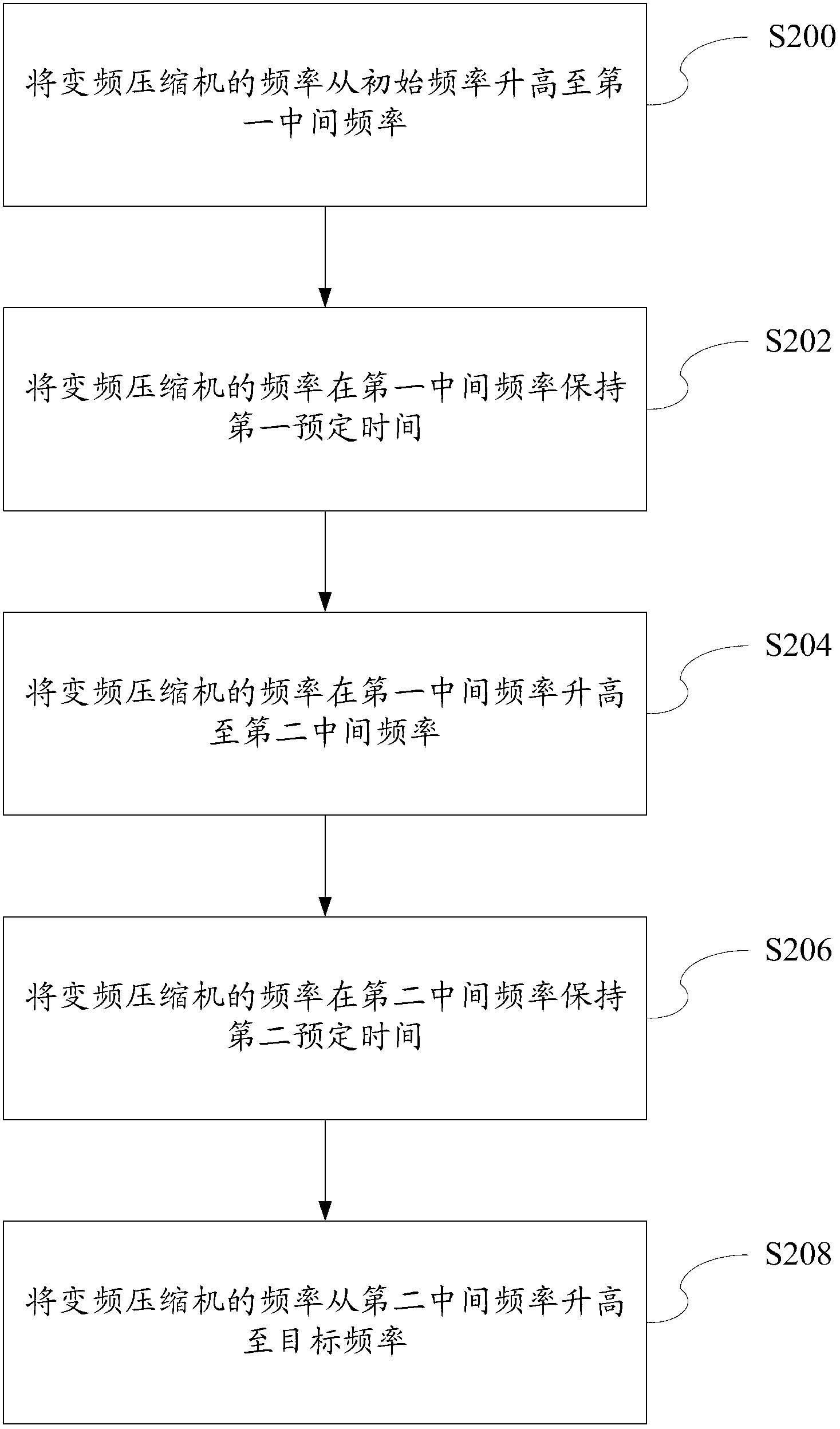

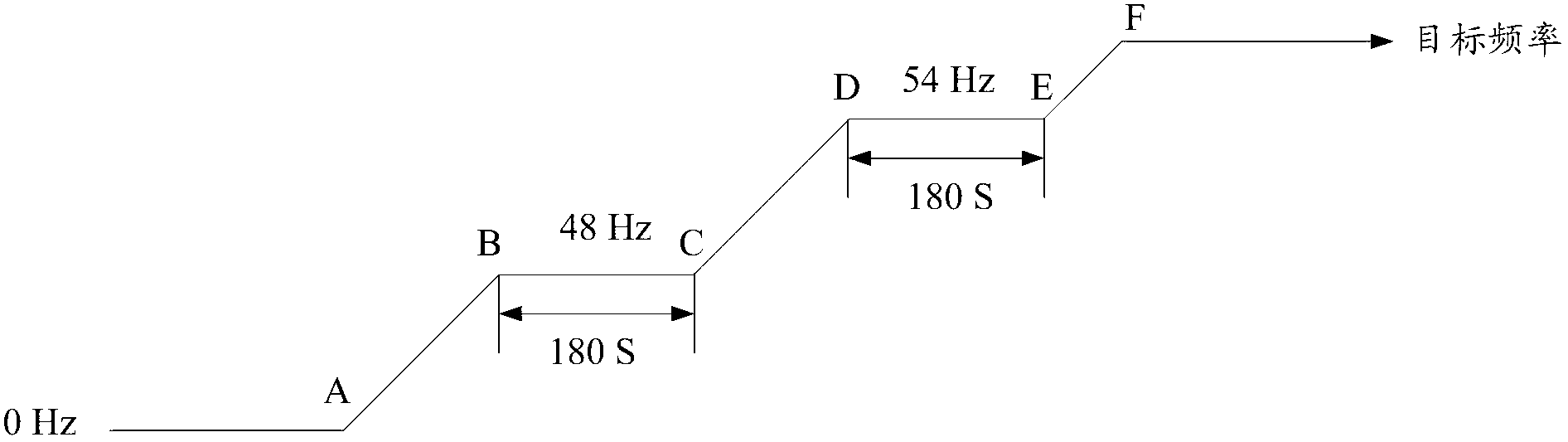

[0023] figure 1 It is a flowchart of a method for starting an inverter compressor according to an aspect of the present invention. exist figure 1 middle:

[0024] Step S100: Increase the frequency of the inverter compressor from the initial frequency to a first intermediate frequency. Wherein, the initial frequency may be 0 Hz. Preferably, the first intermediate frequency may be between 40 Hz and 60 Hz. The first intermediate frequency can be found through the oil return quantity of the inverter compressor. For example, look for a low frequency in the starting frequency of the variable frequency compressor, and then observe the oil return amount of the variable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com