Whole-bundle disanchoring device and disanchoring method adopting same

A technology for withdrawing anchors and anchors, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of difficult construction, poor construction flexibility, and cumbersome demolition and construction techniques, and achieve good safety and stability, structural The effect of reasonable design and shortening the demolition period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

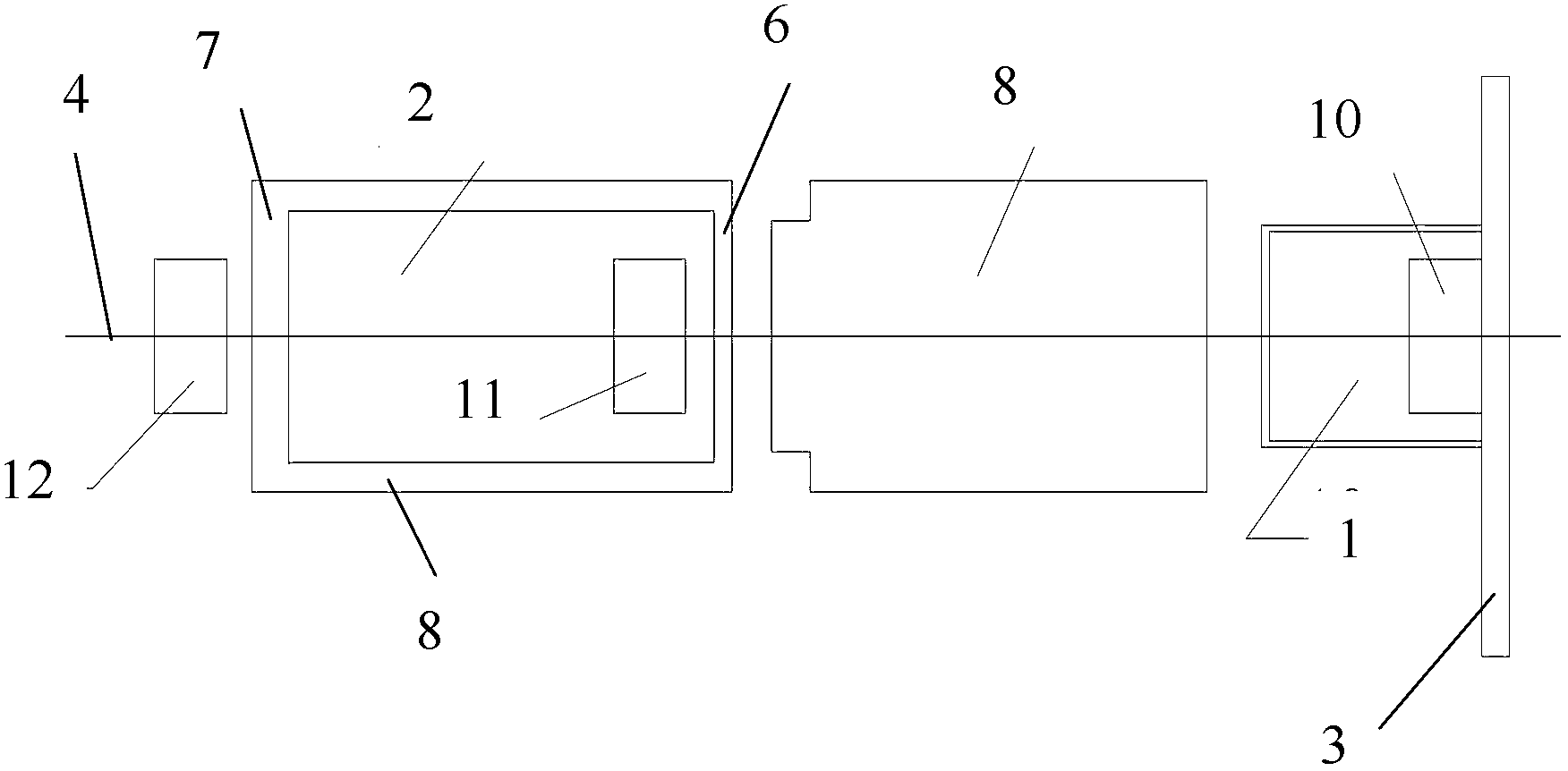

[0021] The entire bundle anchor retractor and the anchor retraction method provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

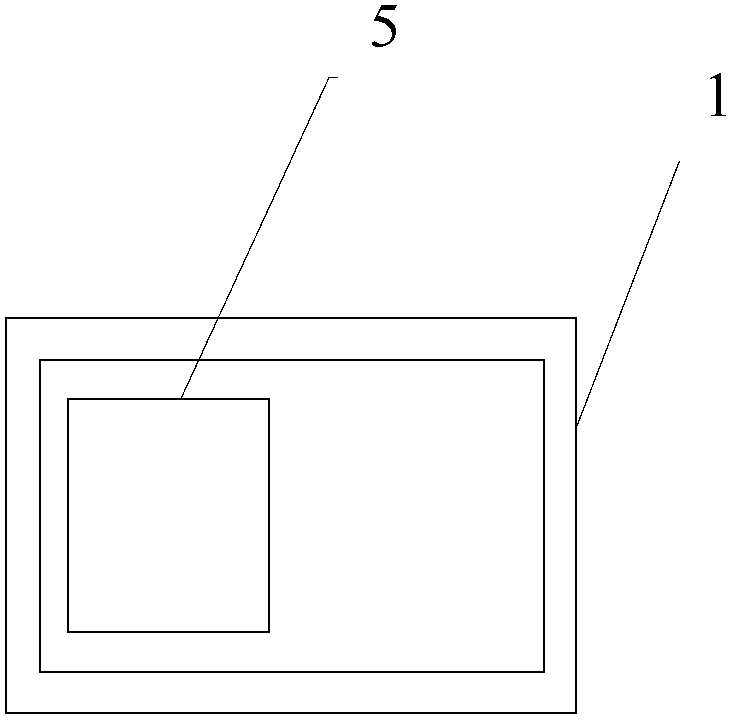

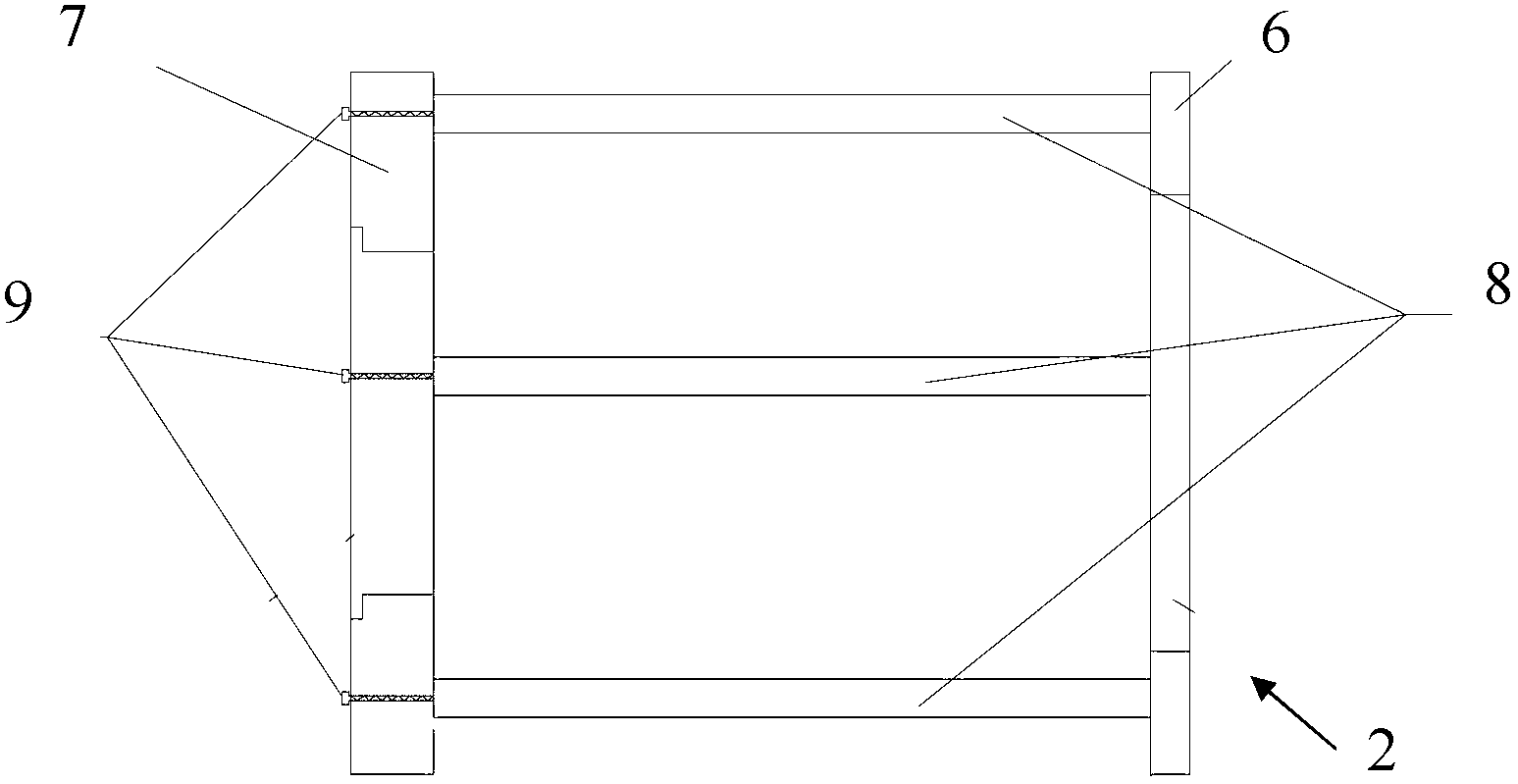

[0022] Such as Figure 1-Figure 3 As shown, the whole bundle anchor retractor provided by the present invention includes a top-front working pile 1 and a top-back anchor 2; wherein the top-front working pile 1 is tubular, installed outside one end of a large prestressed member 3, and the inside runs through the large prestressed component 3. The prestressed steel hinge beam 4 at one end of the stress member 3, and two working hand holes 5 are formed on the peripheral wall of the front working pile 1; On the outer side of the outer end of the front working pile 1, there is a hollow jack 8 between it and the front working pile 1, and the jacking and retreating anchor 2 is composed of a first ring 6, a second ring 7 and a plurality of cylinders 8, wherein The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com