How to remove a steel chimney

A technology of chimneys and steel wire ropes, applied in towers, buildings, building maintenance, etc., can solve the problems of unsatisfactory construction requirements, low construction efficiency, and long demolition period, so as to shorten the demolition period, improve construction efficiency, and ensure construction safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand and implement the present invention, but the examples given are not intended to limit the present invention.

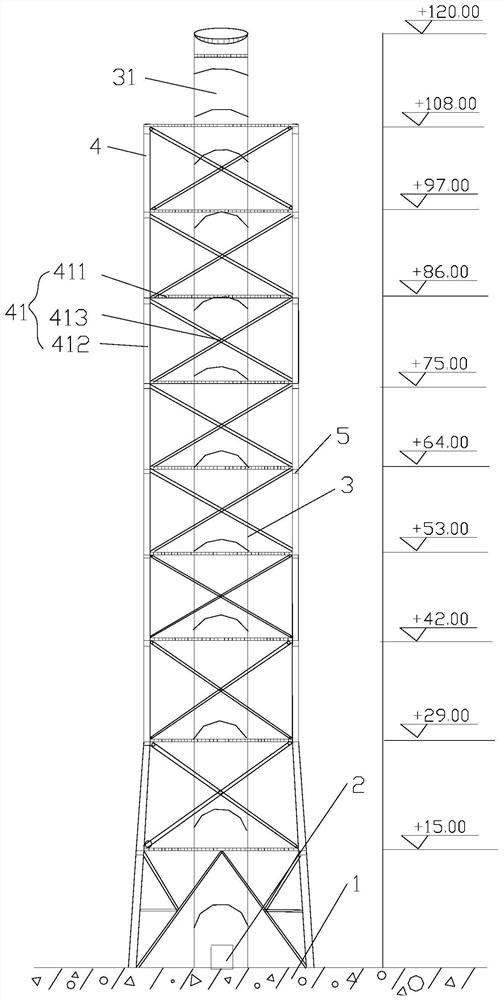

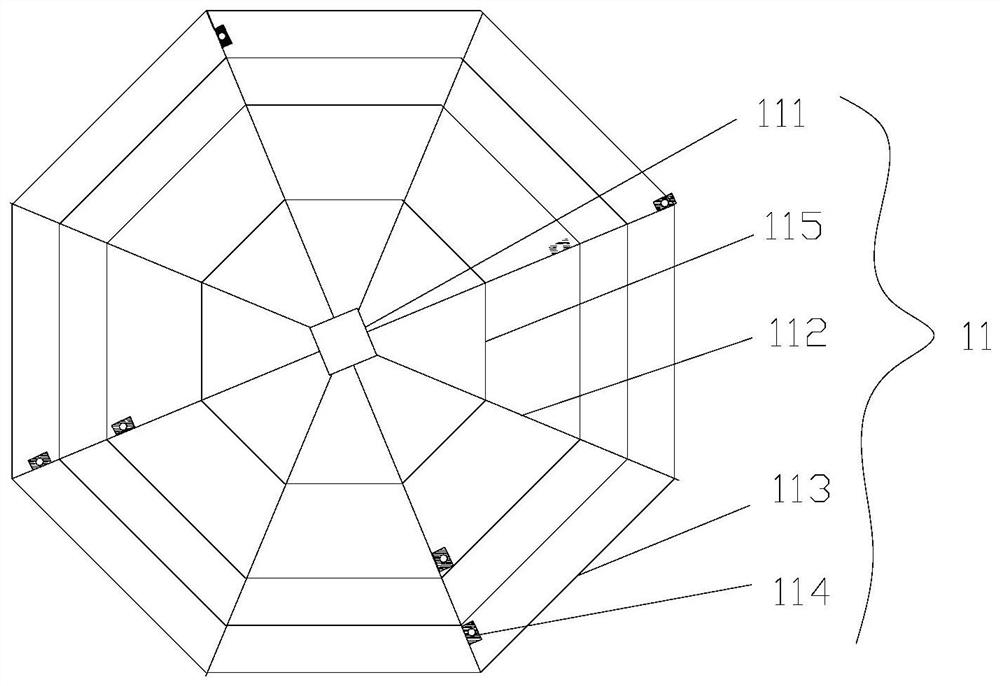

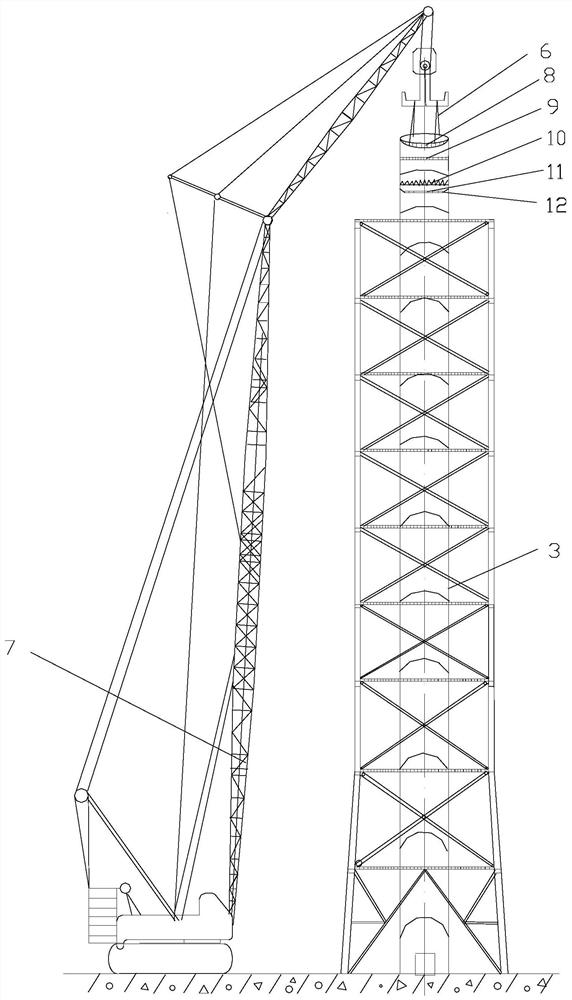

[0034] Such as Figure 1-Figure 4 As shown, a method for removing a steel chimney, the chimney is installed on the floor 1, an access door 2 is arranged at the bottom of the chimney, and a chimney tower cap 8 is arranged on the top. The chimney includes a chimney barrel and a tower arranged on the periphery of the chimney barrel 3. The frame 4 and the tower 4 are mainly composed of a plurality of frame units 41 connected from top to bottom. A frame platform 411 is provided in the frame unit 41, and a frame railing is provided on the frame platform 411. The removal method includes the following steps:

[0035] 1) Calculate the segmented removal height of the chimney shell 3 according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com