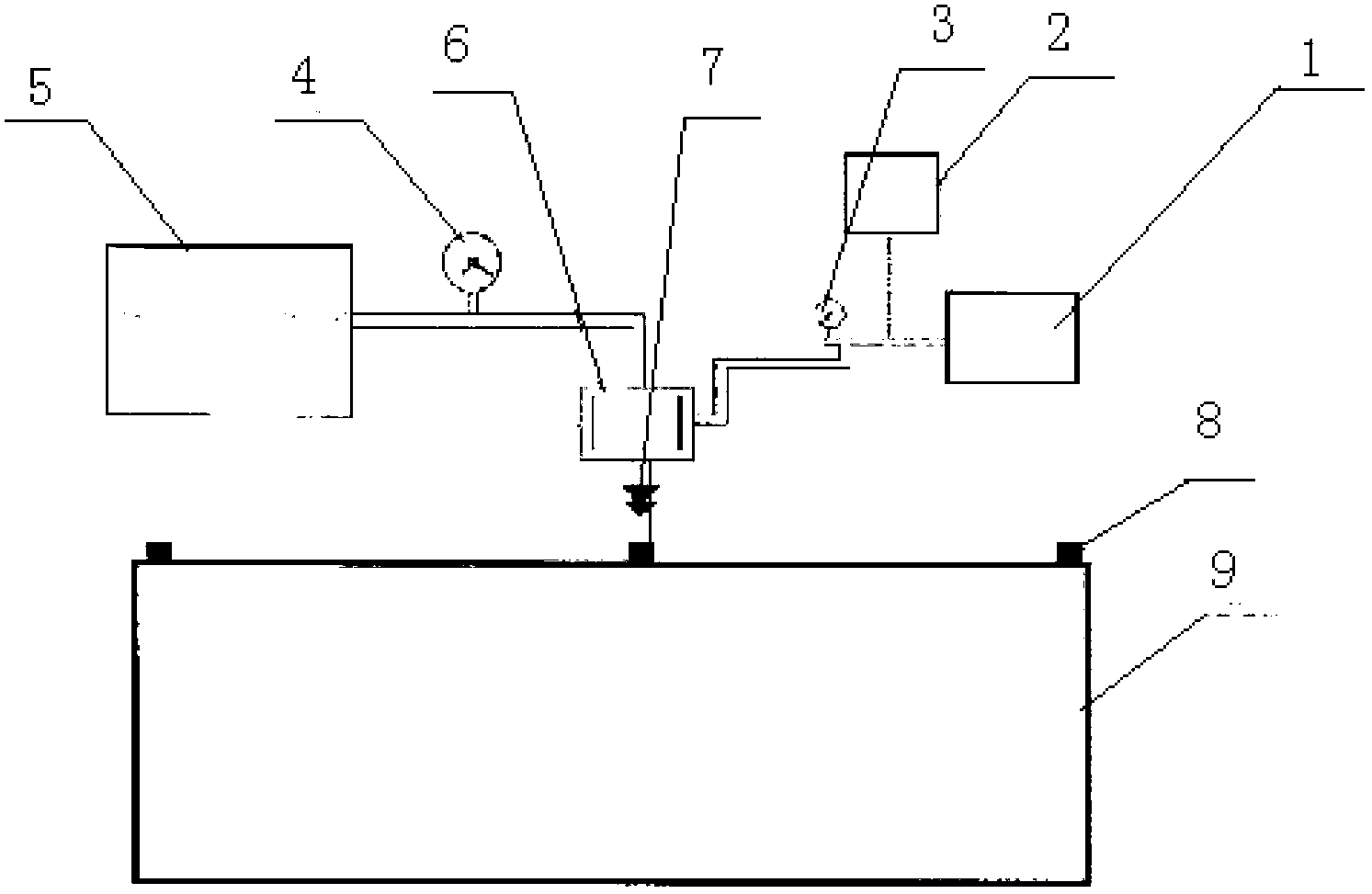

Method for achieving slurry water separation and solidification of filling soil by utilizing filling bag and construction device

A construction device and bag filling technology, which is applied in fertilization devices, chemical instruments and methods, filling, etc., can solve problems such as poor soil consolidation effect, long mud-water separation time, and reduced construction speed, so as to achieve convenient local materials, The effect of shortening the construction period and accelerating the consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Application of the method of the present invention in land reclamation

[0045] 1. Processing and production of filling bags:

[0046] The woven bag used to make the filling bag is made of polypropylene and woven needle-punched composite geotextile, with a weight of 200g / m 2 , the warp and weft yarn is 15 wires / inch, the thickness is 0.8mm, the tensile strength in the warp and weft direction is 1000N / 5cm, and the equivalent aperture is O 90 is 0.3mm, and the permeability coefficient is 10.0×10 -3 cm / s.

[0047] The filling bag is processed into a rectangular shape, with a length of 10-50 meters and a width of 4-8 meters. It is manufactured according to the embankment construction drawing design drawings during processing. At the same time, combined with the control of construction settlement and increasing the shrinkage rate by 3%, according to the conventional method, the tension bars are set along the length direction to control the thickness of the filling bag. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com