Printed non-woven fabric and manufacturing device

A non-woven fabric, printing roller technology, applied in non-woven fabrics, printing, printing machines, etc., can solve the problems of difficult coloring, single pattern of hot air non-woven fabrics, etc., and achieve the effect of improving color, fast penetration, and improving appearance aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

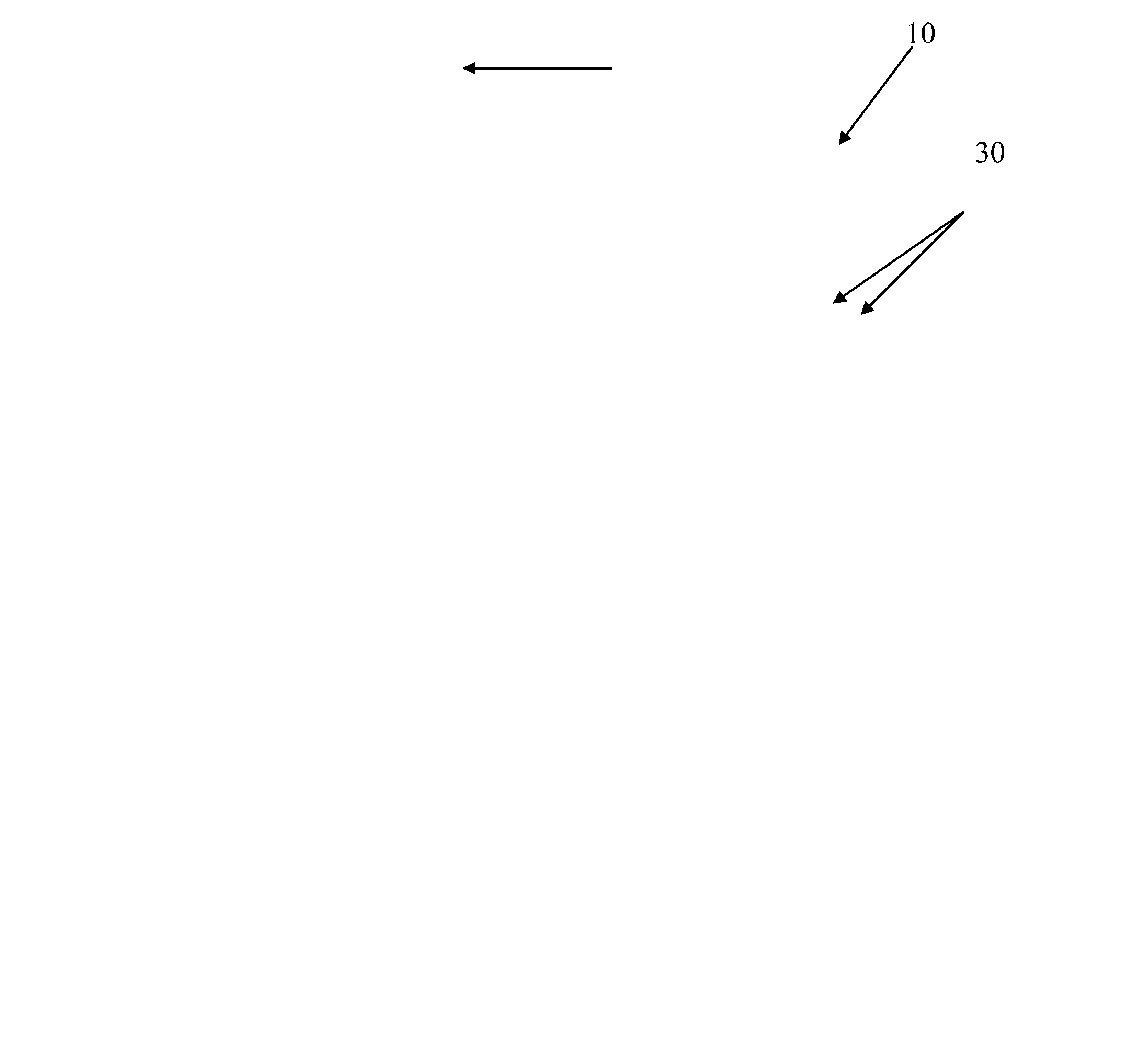

[0022] The nonwoven fabric 10 of the present invention is in figure 1 It is shown in plan view. This pattern is only an example of the new method of printing air-through nonwovens. In the formal production process, printed air-through nonwovens with different appearance effects can be produced according to the pattern. exist figure 1 In , the direction of the horizontal arrow indicates the running direction of the device. The printed nonwoven 10 is printed on the device in the running direction of the horizontal arrow. The nonwoven fabric 10 forms a pattern area in the running direction of the device, that is, various flower patterns formed by the concave-convex area 30 .

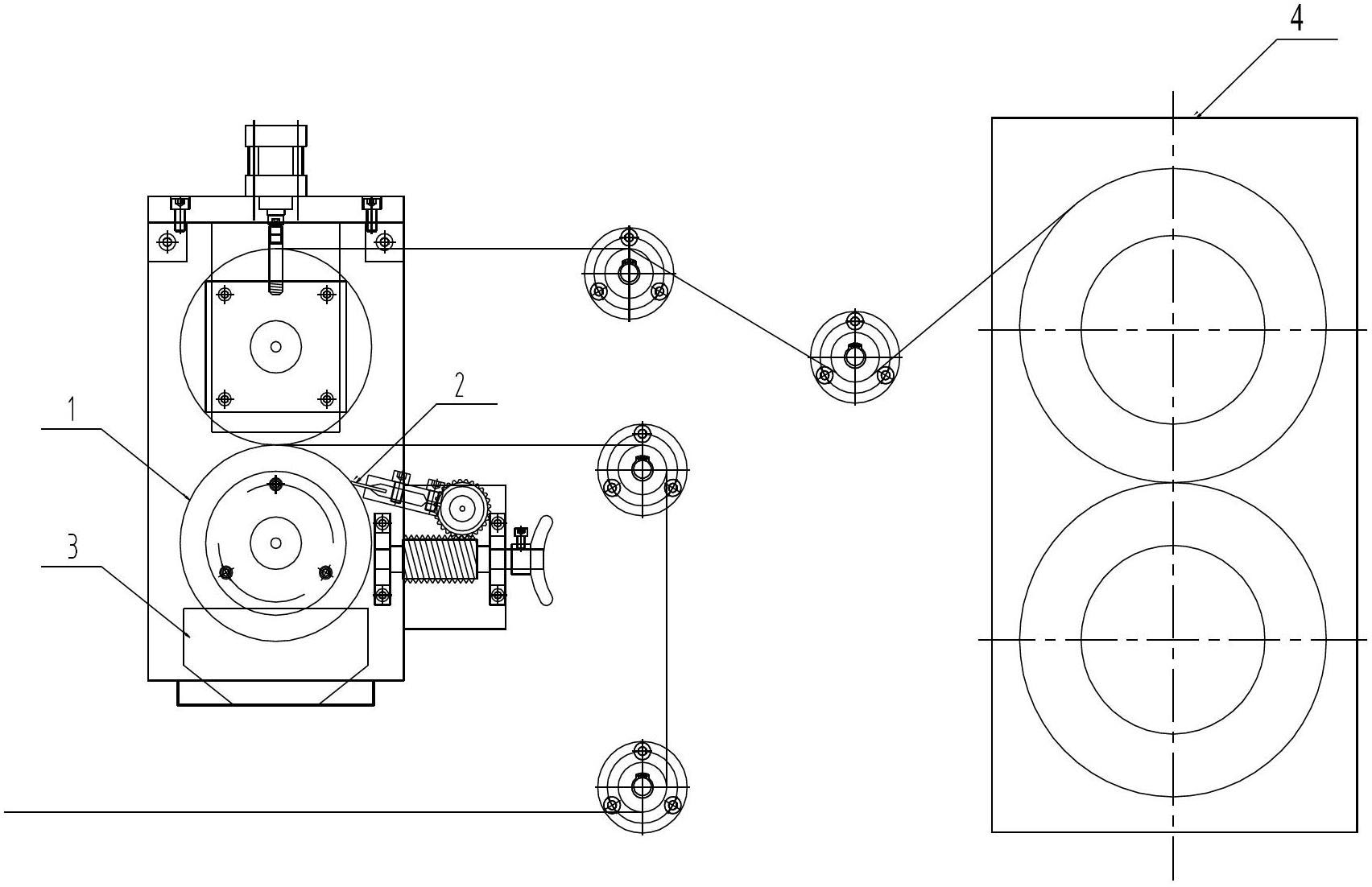

[0023] figure 2 A schematic diagram of the printing roller is shown, 1 indicates the printing roller engraved with different patterns, 2 indicates the scraper, 3 ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com