Device for drawing fabric breadth of surface-shaped textile from textile machine, especially tricot machine

A warp knitting machine and fabric width technology, which is applied in warp knitting, textiles, papermaking, knitting, etc., and can solve problems such as the appearance of untidy fabrics and the reduction of fabric width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

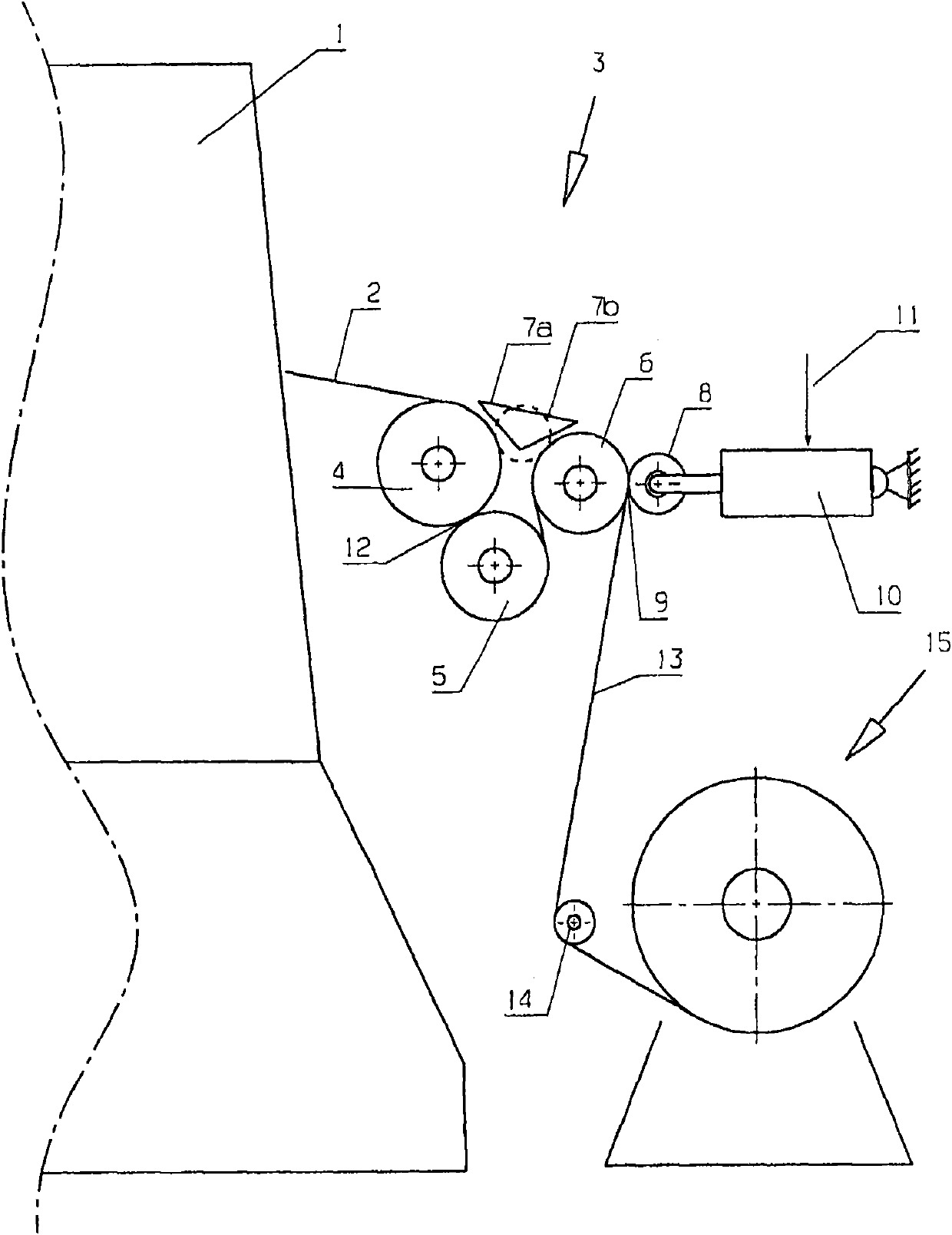

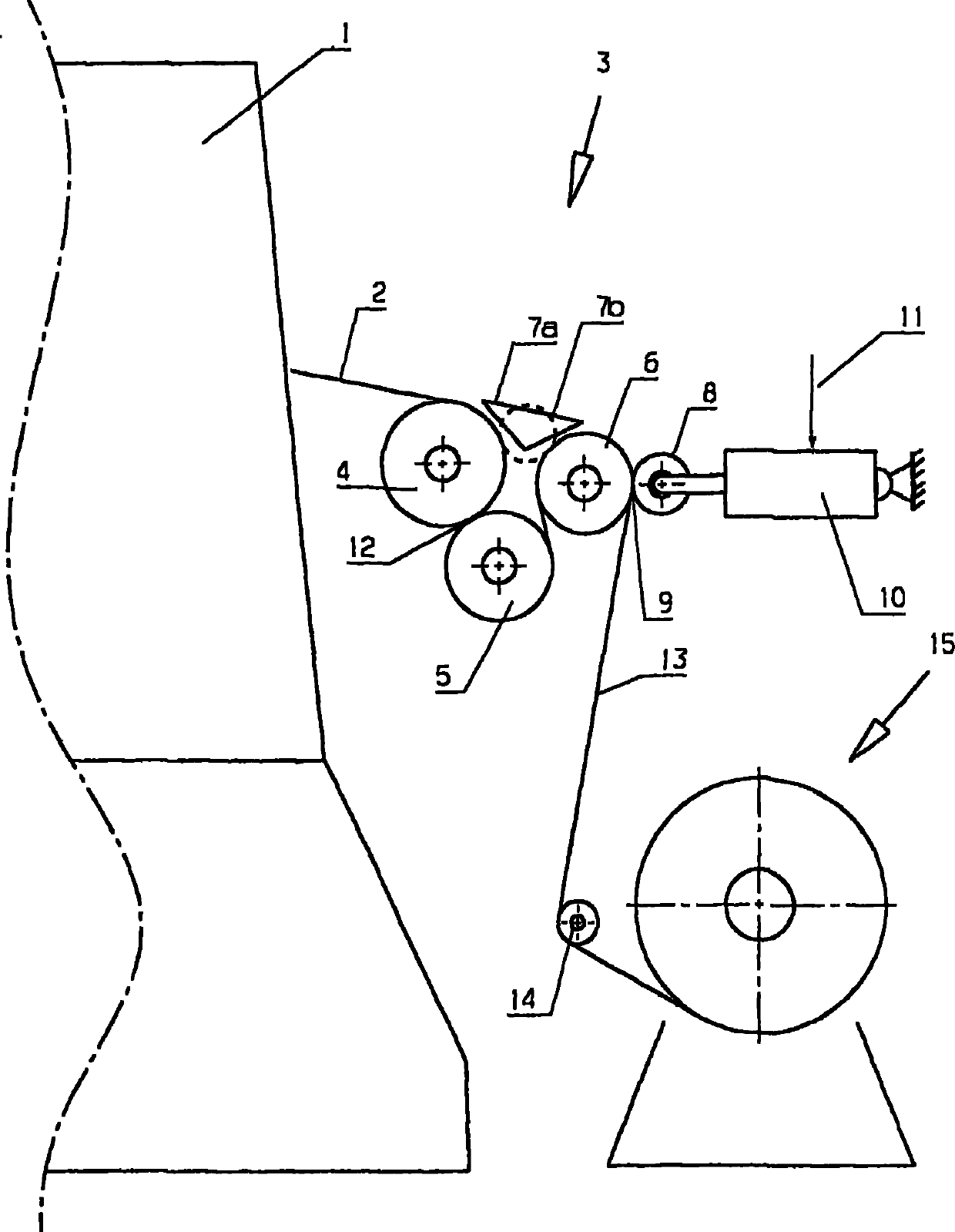

[0021] The figure schematically shows a textile machine 1 , for example a warp knitting machine, which produces a textile web 2 in the form of a knitted fabric. The textile web 2 is a highly elastic textile surface in which highly elastic threads are processed while being stretched. The width of the textile web 2 at the outlet of the textile machine 1 is determined by the production process and by the production width. During production, the textile web 2 is thus kept in the required width by the weaving machine 1 .

[0022] After leaving the textile machine 1, however, there are practically no longer any forces against the relaxation of the fabric web 2, ie the shrinkage transversely to the production and travel direction of the fabric web 2. As soon as the textile web 2 leaves the weaving machine 1 it therefore tries to reduce its width.

[0023] The textile web 2 is withdrawn from the textile machine 1 via a withdrawal device 3 . In the present exemplary embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com