Production process of recycled aluminum

A production process and recycled aluminum technology, applied in the direction of stirring devices, lighting and heating equipment, furnace components, etc., can solve the problems of unable to stir the aluminum liquid evenly, high degree of burning of the aluminum liquid, waste of raw materials, etc., and reduce the cost of equipment purchase , Improve the aluminum output rate and output, and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

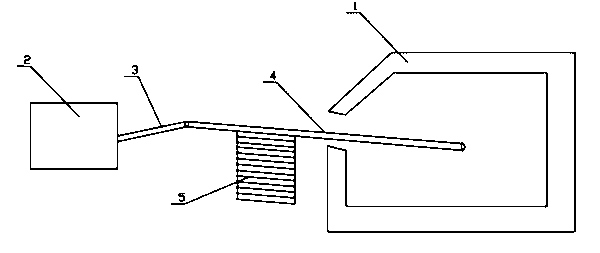

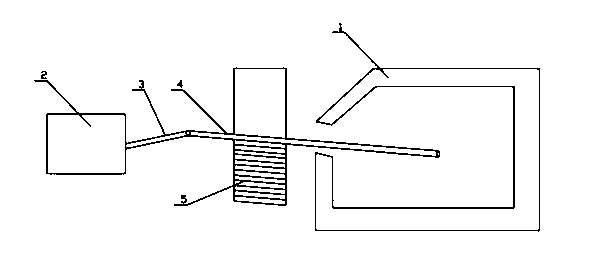

[0053] A production process for recycled aluminum, including pre-preparation of waste aluminum, batching, melting, testing components, and pouring and casting to obtain the final recycled aluminum product. The melting process includes the following process steps:

[0054] A. Put the scrap aluminum material after batching into the smelting furnace;

[0055] B. Smelting at 650°C and stirring at the same time. Specifically, an air compressor is used for stirring. The air compressor is connected to one end of the vibrating rod through a pipeline, and the other end of the vibrating rod is extended into the hearth of the smelting furnace, and stirred Turn on the air compressor at the same time, drive the vibrating rod to vibrate and stir in the furnace, the stirring time is 10min, and feed after the stirring is completed;

[0056] C, repeat twice according to the technology in step B, promptly carry out stirring, feeding, stirring, feeding successively;

[0057] D, stir once accord...

Embodiment 2

[0062] A production process for recycled aluminum, including pre-preparation of waste aluminum, batching, melting, testing components, and pouring and casting to obtain the final recycled aluminum product. The melting process includes the following process steps:

[0063] A. Put the scrap aluminum material after batching into the smelting furnace;

[0064] B. Smelting at 760°C and stirring at the same time. Specifically, an air compressor is used for stirring. The air compressor is connected to one end of the vibrating rod through a pipeline, and the other end of the vibrating rod is extended into the hearth of the smelting furnace, and stirred Turn on the air compressor at the same time, drive the vibrating rod to vibrate and stir in the furnace, the stirring time is 15min, and feed after the stirring is completed;

[0065] C, repeat twice according to the technology in step B, promptly carry out stirring, feeding, stirring, feeding successively;

[0066] D, stir once accord...

Embodiment 3

[0071] A production process for recycled aluminum, including pre-preparation of waste aluminum, batching, melting, testing components, and pouring and casting to obtain the final recycled aluminum product. The melting process includes the following process steps:

[0072] A. Put the scrap aluminum material after batching into the smelting furnace;

[0073] B. Smelting at 705°C and stirring at the same time. Specifically, an air compressor is used for stirring. The air compressor is connected to one end of the vibrating rod through a pipeline, and the other end of the vibrating rod is extended into the hearth of the smelting furnace, and stirred Turn on the air compressor at the same time, drive the vibrating rod to vibrate and stir in the furnace, the stirring time is 12.5min, and feed after the stirring is completed;

[0074] C, repeat twice according to the technology in step B, promptly carry out stirring, feeding, stirring, feeding successively;

[0075] D, stir once acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com