Method for preparing leucine aminopeptidase through fermentation of bacillus subtilis engineering bacteria

A technology of Bacillus subtilis and leucine aminopeptidase, which is applied in the field of enzyme preparations and food additives, and can solve the problems of affecting food flavor, unpleasantness, and restricting popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

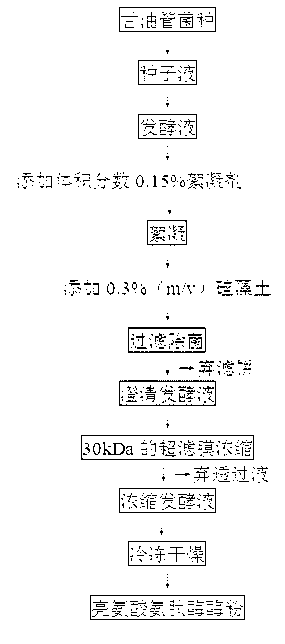

Method used

Image

Examples

Embodiment 1

[0038] Insert Bacillus subtilis engineering bacteria: recombinant plasmid PMA5-SAP into the seed solution through a glycerol tube, and after expanding the culture, put it into 4.5L fermentation medium according to the inoculum size of 2%. The fermenter is a fully automatic 7L fermenter , Bioflo 110, NBS Company of the United States, the composition of the fermentation medium is as described in the instructions. The initial pH of the fermentation medium is 8.0, the culture temperature is 37°C, the stirring speed is 300-600rpm, the ventilation rate is 1.2:1, the tank pressure is maintained at 0.06-0.08MPa, the minimum DO is controlled at 30%, DO is coupled with the speed, and cultured for 30h . After the fermentation, 4.2L of fermented liquid was obtained, and 6.3mL of cationic flocculant (Kemira, USA) was added to the fermented liquid, and stirred continuously at a temperature of 20-30°C, and rapid stirring was started to mix the flocculant with the fermented liquid Evenly, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com