Process for preparing biofuel from biological waste

A bio-waste, bio-fuel technology, applied in the direction of bio-fuel, waste fuel, fuel, etc., can solve the problems of low combustion rate, wet bio-waste, low rate of return, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

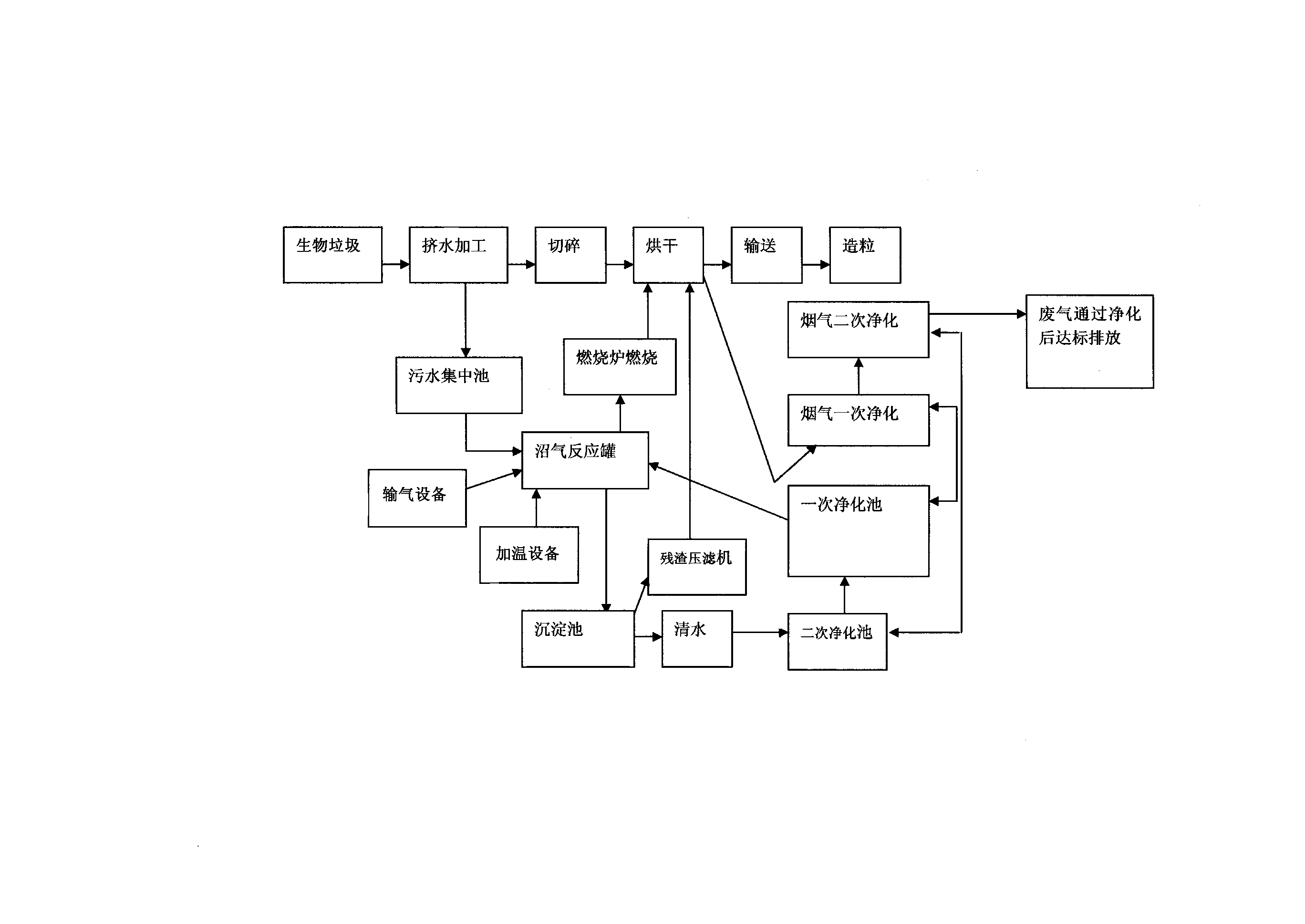

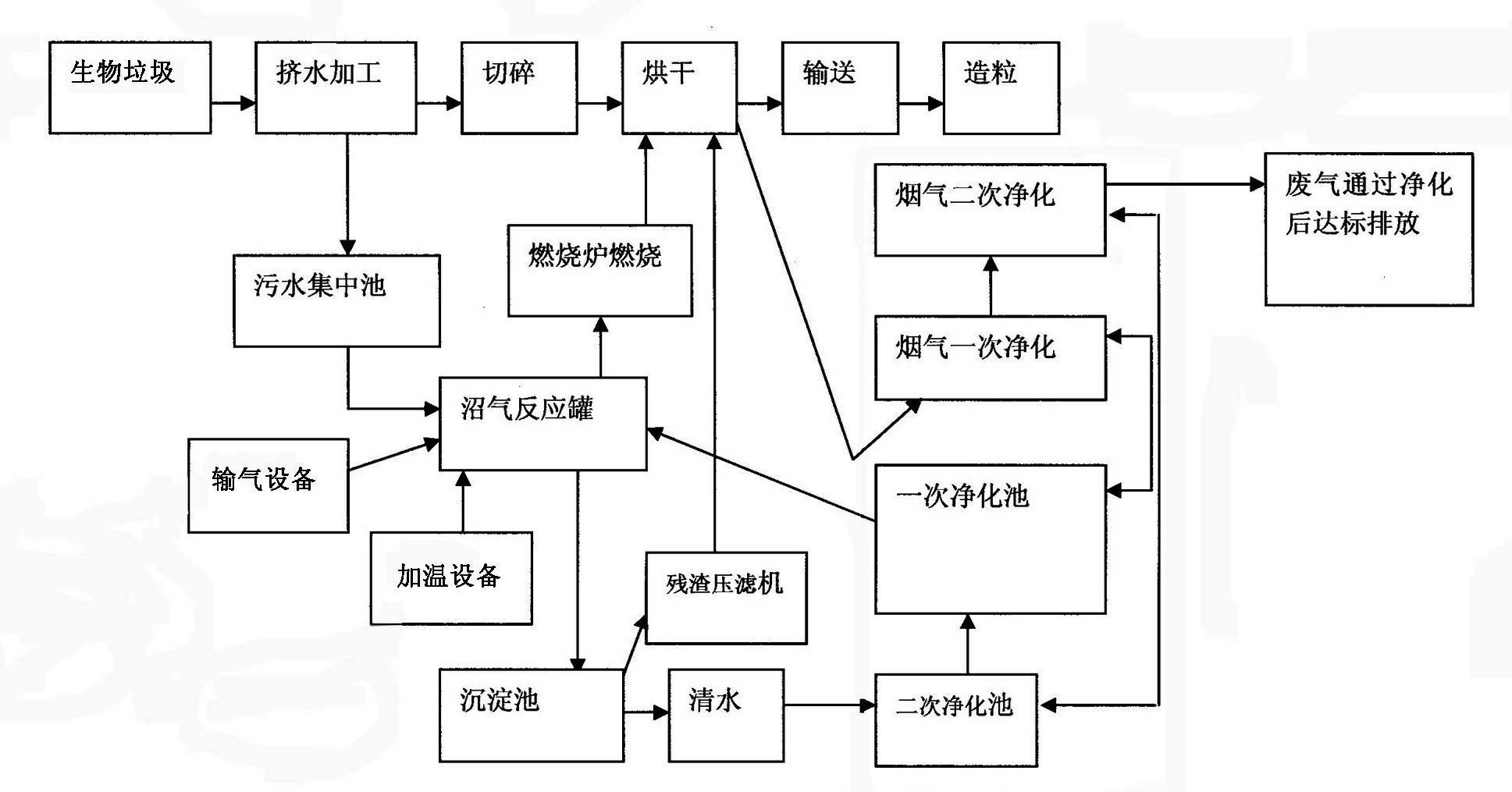

[0014] As shown in the figure, the specific process flow of the present invention includes:

[0015] First, the biological waste is squeezed to process water, and the dehydration reaches about 35%. The squeezing process can use drum extrusion or flat filter technology. The biological waste after squeezing is divided into two categories and processed at the same time. The first type of sewage enters the sewage concentration tank; the sewage in the sewage concentration tank is sent to the biogas reactor; the biogas reactor is connected with heating equipment and gas transmission equipment, and the gas transmission equipment is connected at the bottom of the biogas reactor. Its function is The stirred reaction tank uses residual biogas, and can kill bacteria in the reaction tank, and the heating equipment can accelerate the reaction in the reaction tank. The biogas produced in the biogas reactor is burned through the combustion furnace, and its heat is sent to the drying equipment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com