Oil-absorption material and preparation method thereof

An oil-absorbing material, polylactic acid technology, which is applied in separation methods, chemical instruments and methods, grease/oily substances/floating matter removal devices, etc. Good oil absorption effect, simple preparation method and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

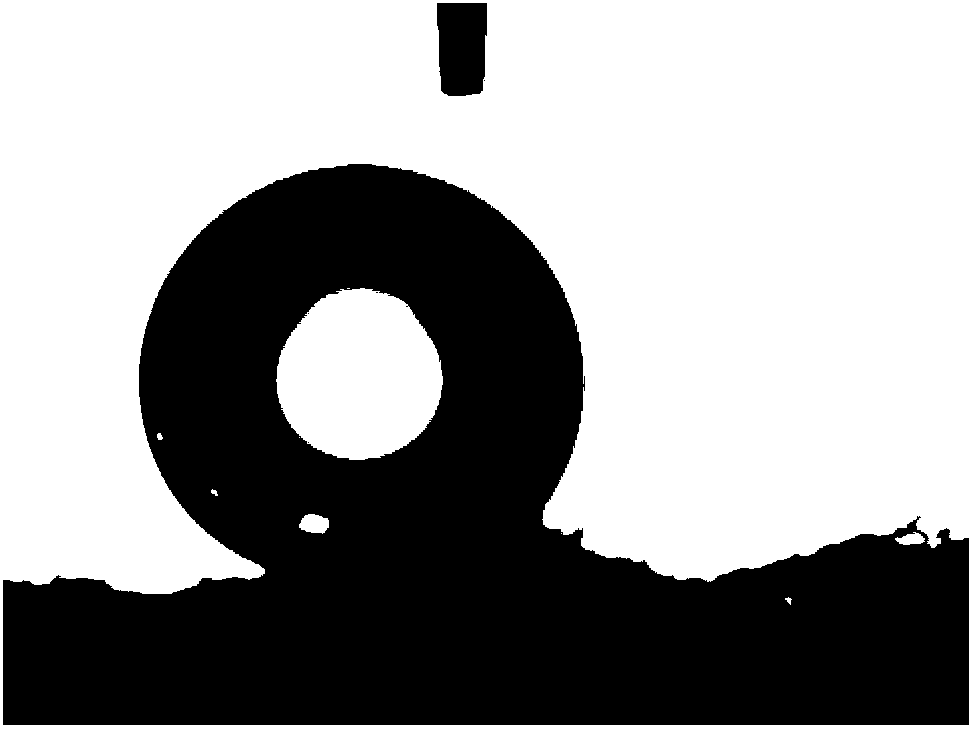

[0042] Embodiment 1, preparation and functional identification of oil-absorbing ball

[0043] 1. Preparation of oil-absorbing balls

[0044] Dissolve PLA (polylactic acid, Shenzhen Guanghua Weiye Industrial Co., Ltd., molecular weight = 69000, L-polylactic acid) in 1,4-dioxane solvent to prepare a PLA solution with a concentration of 0.1g / mL, and cast the PLA solution Put it into a corresponding spherical mold, and immerse in absolute ethanol for phase separation for 30 minutes. The 1,4-dioxane solvent is removed and PLA precipitates into a solid at the same time. The solid phase is collected as an oil-absorbing material, and then it is simply processed ( dry) to get oil-absorbing balls.

[0045] 2. Functional identification of oil-absorbing materials

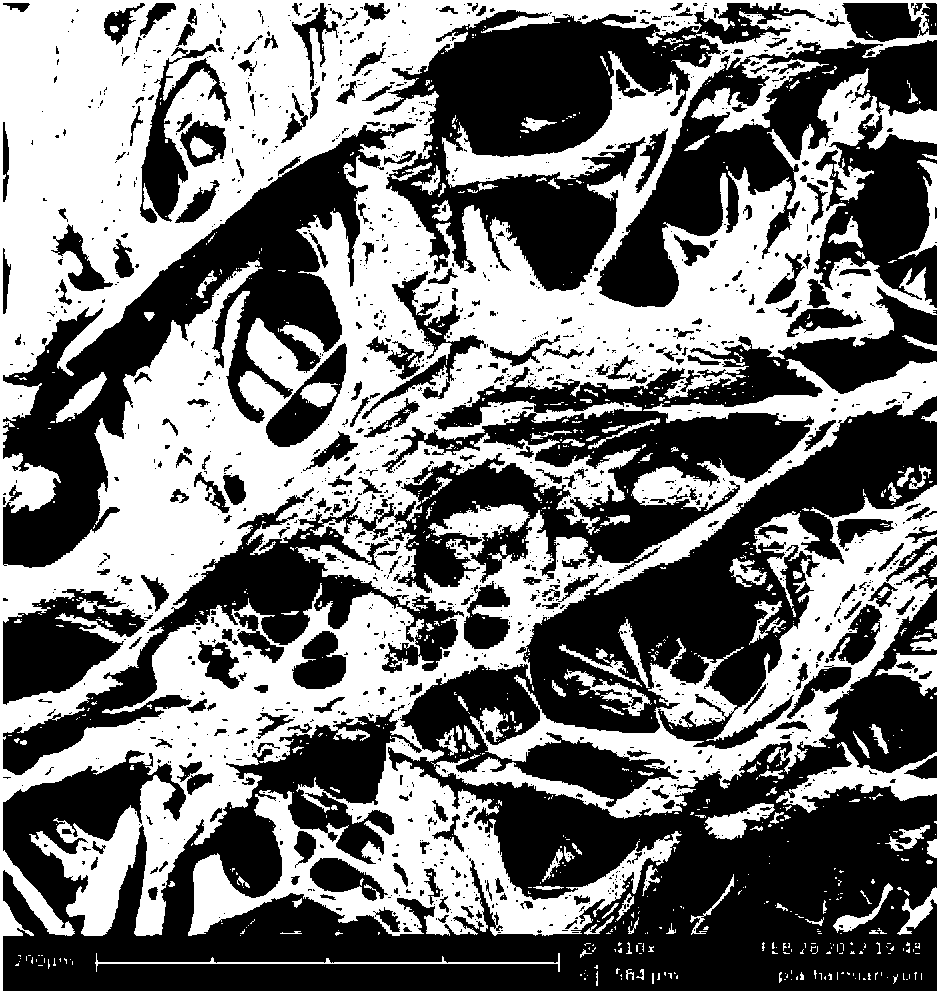

[0046] The oil-absorbing ball obtained in the above 1 was scanned by an electron microscope, and the surface morphology was observed at a magnification of 410 times. The results were as follows figure 1 As shown, it can be s...

Embodiment 2

[0050] Embodiment 2, preparation and functional identification of oil-absorbing sheet

[0051] 1. Preparation of oil-absorbing tablets

[0052] Dissolve PLA (polylactic acid, Shenzhen Guanghua Weiye Industrial Co., Ltd., L-polylactic acid) with a molecular weight of 69,000 in 1,4-dioxane solvent to prepare a PLA solution with a concentration of 0.1g / mL. Spread on a glass substrate, immerse in absolute ethanol for phase separation for 30 minutes, remove the 1,4-dioxane solvent and at the same time PLA precipitate into a solid, collect the solid phase as the oil-absorbing material, the shape is a sheet, and then the sheet Put the shaped oil-absorbing material at 40°C and dry in an oven to obtain an oil-absorbing sheet.

[0053] 2. Function identification of oil-absorbing sheet

[0054]Scan the oil-absorbing sheet obtained in the above 1 with an electron microscope, and magnify it 14,000 times to observe the surface morphology. The results are as follows: Figure 5 As shown, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com