Process for continuously preparing superfine nitroguanidine

A technology of ultra-fine nitroguanidine and preparation process, which is applied in the field of preparation of nitroguanidine, can solve the problems of large crystal particles and cannot be used in the airbag industry, etc., and achieves the effects of stable product quality, reduced labor intensity, and improved operating environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

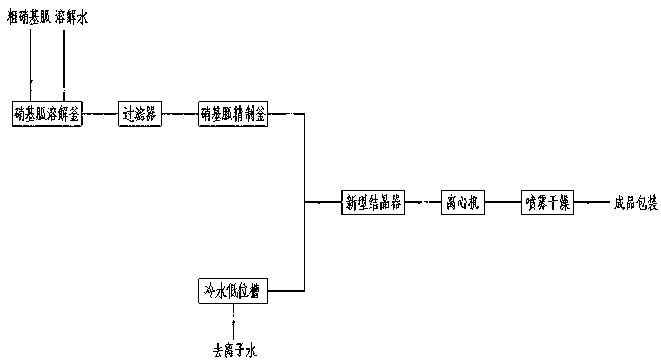

Image

Examples

Embodiment 1

[0024] Put 100Kg of nitroguanidine into a 1000L stainless steel reaction kettle, add 700L of dissolved water, heat to reflux at 95°C under stirring, and keep warm for 20 minutes; start the filter pump, and transport the dissolved material to the refining kettle through a precision filter; start the cold water pump , pre-cool the water to 5°C, control the flow of cold water to 500L / hr, after stabilization, start the material pump, control the flow of material to 100L / hr, enter the crystallizer, then enter the receiving tank, and obtain ultra-fine nitroguanidine through centrifugal dehydration and drying 55Kg, the measured Fischer particle size is 4.5μm;

Embodiment 2

[0026] Put 100Kg of nitroguanidine into a 1000L stainless steel reaction kettle, add 700L of dissolved water, heat to reflux at 102°C under stirring, and keep warm for 40 minutes; start the filter pump, and transport the dissolved material to the refining kettle through a precision filter; start the cold water pump , pre-cool the water to 0°C, control the flow of cold water to 700L / hr, after stabilization, start the material pump, control the flow of material to 100L / hr, enter the crystallizer, then enter the receiving tank, and obtain ultra-fine nitroguanidine through centrifugal dehydration and drying 50Kg, the measured Fischer particle size is 3.0μm;

Embodiment 3

[0028] Put 100Kg of nitroguanidine into a 1000L stainless steel reaction kettle, add 700L of dissolved water, 2.5Kg of catalyst, heat to reflux at 105°C under stirring, and keep warm for half an hour; start the filter pump, and transport the dissolved material to the refining kettle through a precision filter Start the cold water pump, cool the water to 0°C in advance, control the flow of cold water to 400L / hr, after stabilization, start the material pump, control the flow of material to 100L / hr, enter the crystallizer, then enter the receiving tank, and obtain super 60Kg of fine nitroguanidine, the crystallization is agglomerated structure after determination, and the Fischer particle size is 4.1 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com