Method and device for comprehensively processing pig dung in large-scale pig farm

A technology for comprehensive treatment and pig manure, applied in the field of comprehensive treatment of pig manure on large-scale pig farms, can solve the problems of high organic load of biogas digesters, affecting the operation of digesters, and atmospheric pollution, etc., to reduce waste water volume and odor, reduce Risk of secondary pollution and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings.

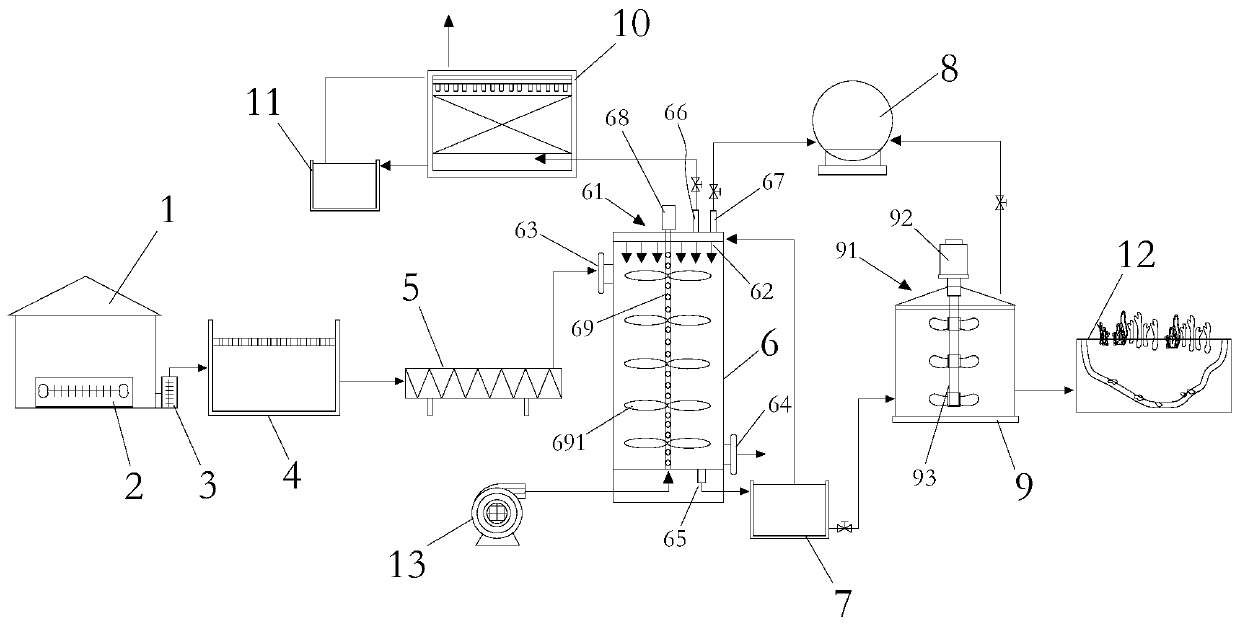

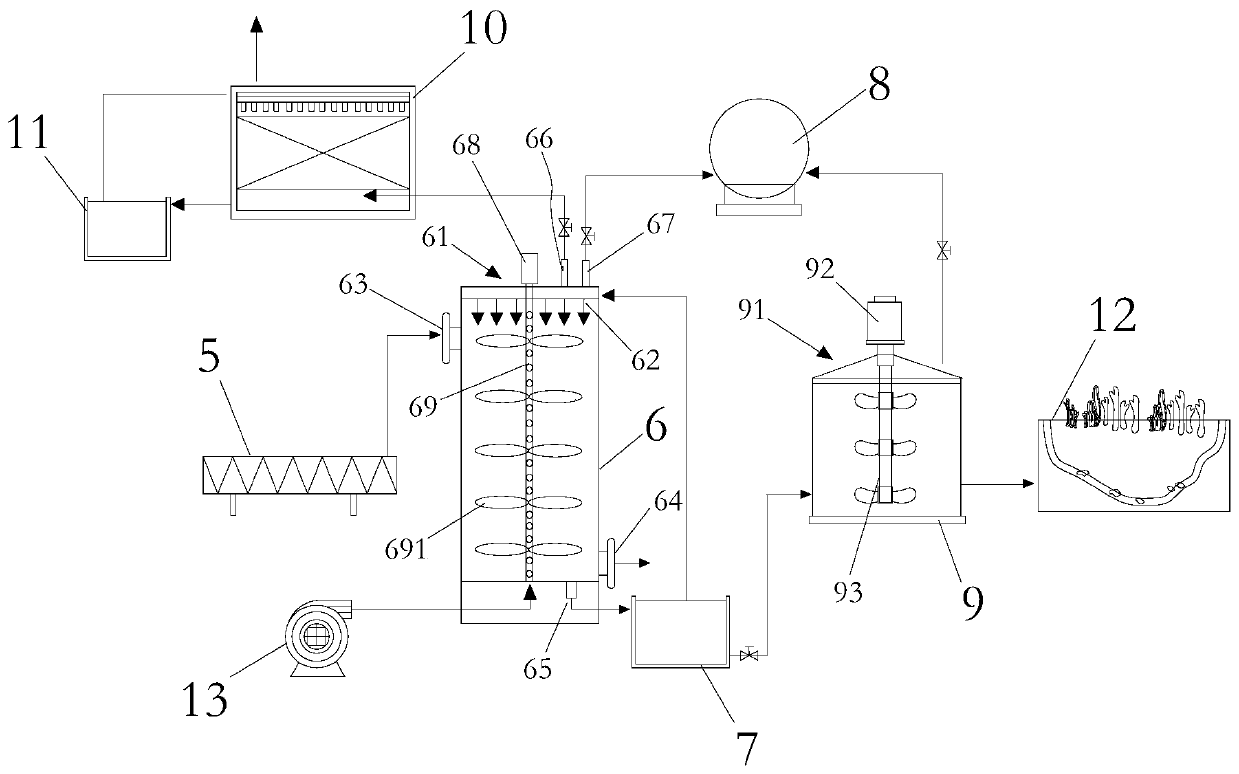

[0027] Such as figure 1 Shown, the method for comprehensive treatment of a kind of large-scale pig farm pig manure of an embodiment provided by the invention comprises the following steps:

[0028] S1. Utilize the mechanical manure scraping facility to collect the pig manure in the pig house 1 and transport it to the manure collection tank 4;

[0029] S2. Add the pig manure in the cesspool 4 to the fermentation tower 6 through the screw conveyor 5, first perform anaerobic dry fermentation of the pig manure to produce biogas, and then perform aerobic composting;

[0030] S3. Pass the biogas produced in the anaerobic dry fermentation process of pig manure in the fermentation tower 6 into the gas storage tank 8 for storage, and pass the odor generated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com