Automatic control system for steam curing of concrete precast pile

An automatic control system, concrete prefabricated pile technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problem of steam waste, achieve the effect of improving quality, avoiding steam waste, and safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

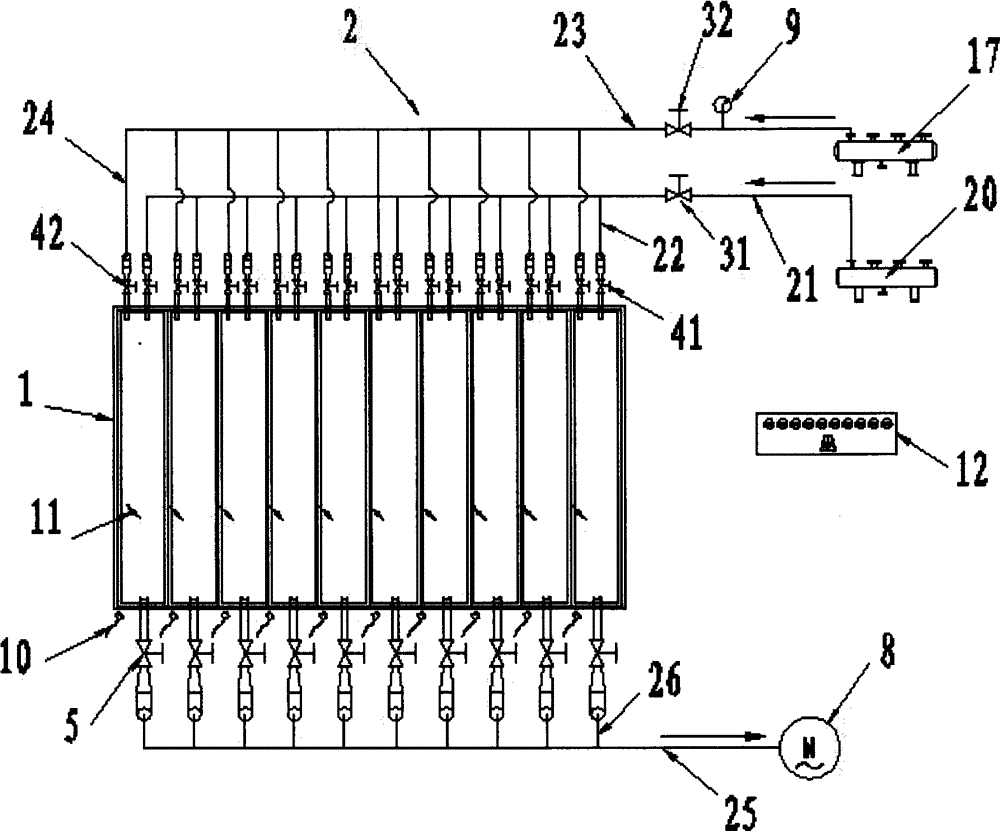

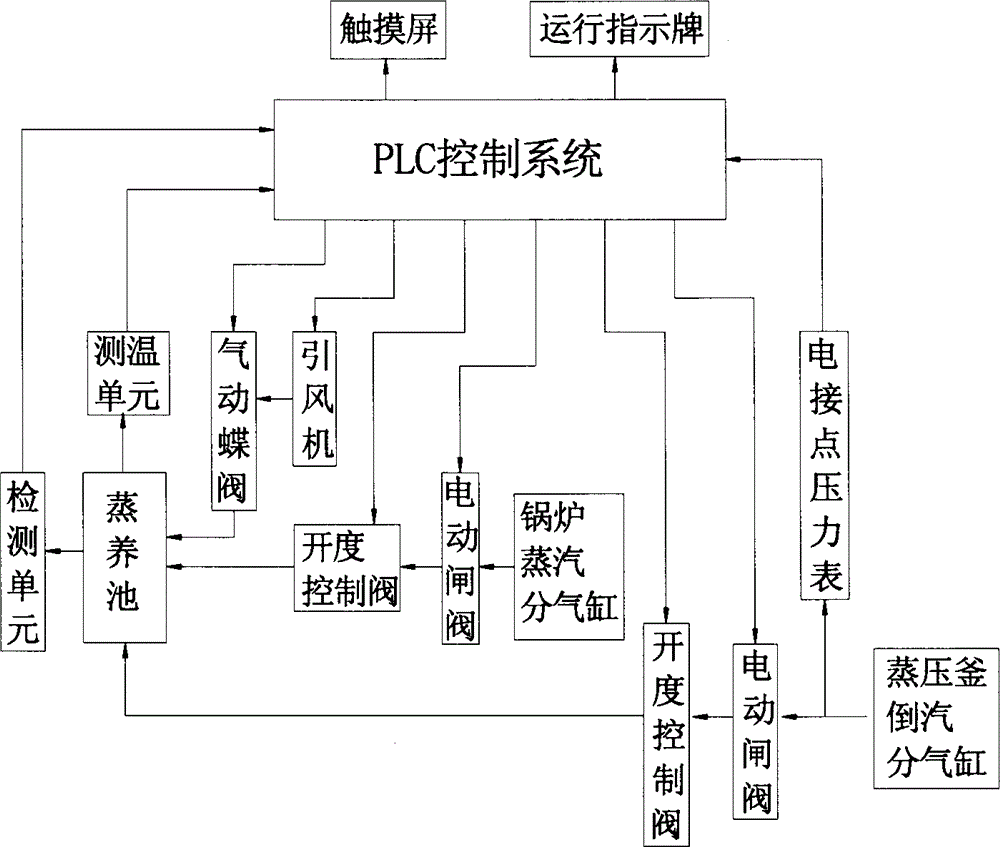

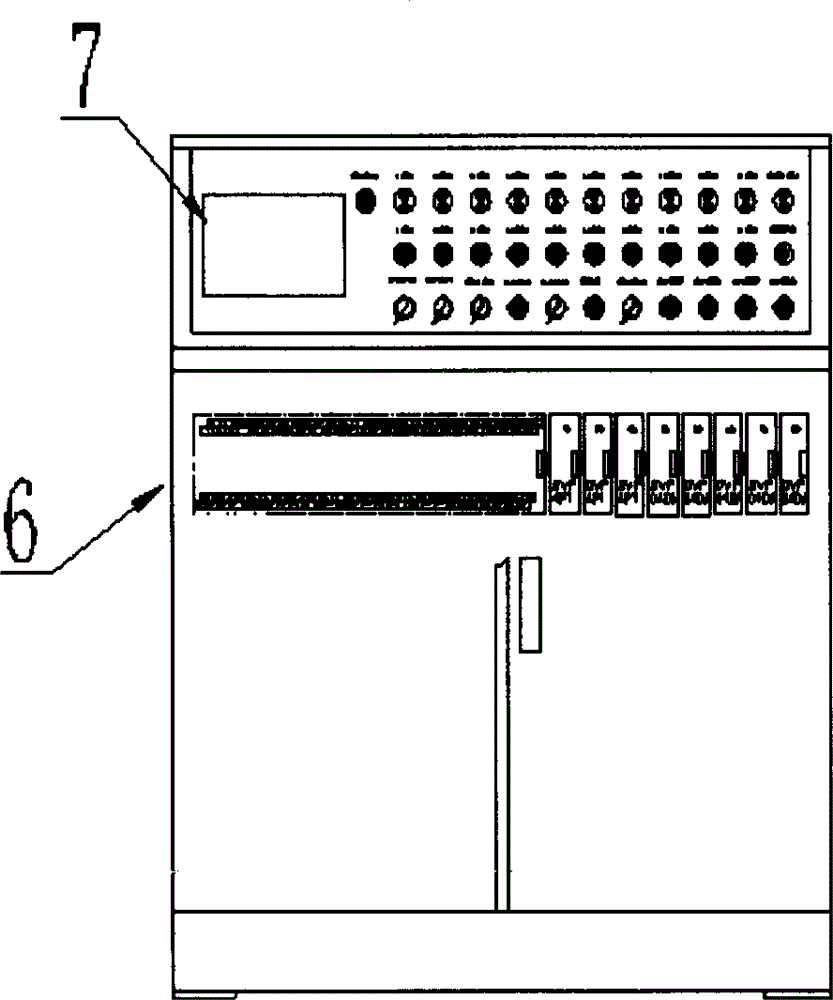

[0013] An automatic control system for steam curing of concrete prefabricated piles according to the present invention, see figure 1 and figure 2 , the system includes a group of steam culture ponds 1, pipeline system 2, induced draft fan 8, steam distribution cylinder 20, steam distribution cylinder 17 and PLC control system 6. The pipeline system 2 includes a steam main pipe 21, a steam branch pipe 22, a steam outlet main pipe 23, a steam outlet branch pipe 24, an exhaust main pipe 25 and an exhaust branch pipe 26; wherein, each steam culture tank is connected to a steam branch pipe and the end of the steam main pipe Connection, the head end of the steam main pipe is connected with the steam sub-cylinder; each steam-curing tank is connected with a steam-inverting branch pipe and the end of the steam-inverting main pipe, and the head end of the steam-inverting main pipe is connected with the steam-inverting sub-cylinder of the autoclave; An exhaust branch pipe connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com