Dedicated machine for slotting both ends of steel pipe

A steel pipe and double-end technology, applied in the field of special machinery for steel pipe double-end grooving, can solve the problems of steel pipe tower size deviation, low work efficiency, high labor intensity, etc., and achieve the effect of ensuring grooving accuracy, improving efficiency and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following, the present invention will be further described through embodiments with reference to the accompanying drawings.

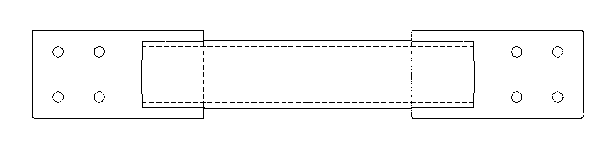

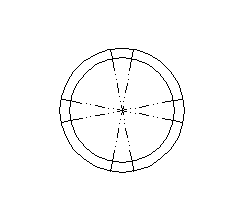

[0023] Reference attached figure 2 , 3 The background art adopts centripetal cutting of steel pipes. The two ends of the steel pipe are slotted and connected to the plug-in board. The gap on one side after the plug-in board is installed is too large, which increases the workload of the plug-in board welding.

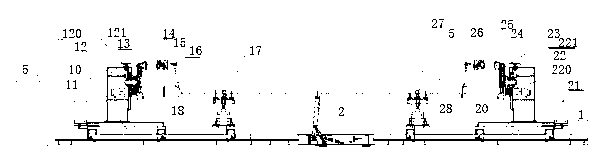

[0024] Reference attached figure 1 , 4 In the embodiment, a special mechanical machine for double-ended grooving of steel pipes has a symmetrical structure. A left mobile trolley 10 is provided on the left side of the base 1, a right mobile trolley 20 is provided on the right side of the base, and a linear guide rail is provided on the base. The wheels of the left and right moving trolleys are matched with linear guides respectively; the left axial sliding seat 11, the left headstock 12 and the left cutting torch 16 are provided on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com