Method for sorting lithium-ion power batteries

A power battery and lithium ion technology, applied in the field of sorting lithium ion power batteries, can solve the problems of consistency and inability to guarantee power batteries, and achieve the effect of convenient use and excellent sorting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

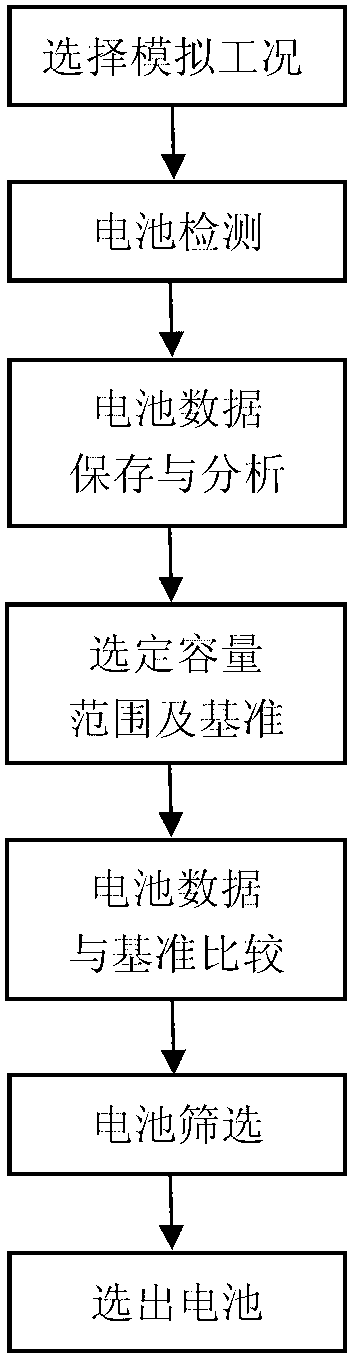

[0027] The battery to be sorted is IFP186596 lithium iron phosphate power battery with a rated capacity of 8Ah. according to figure 1 The method steps shown sort battery packs.

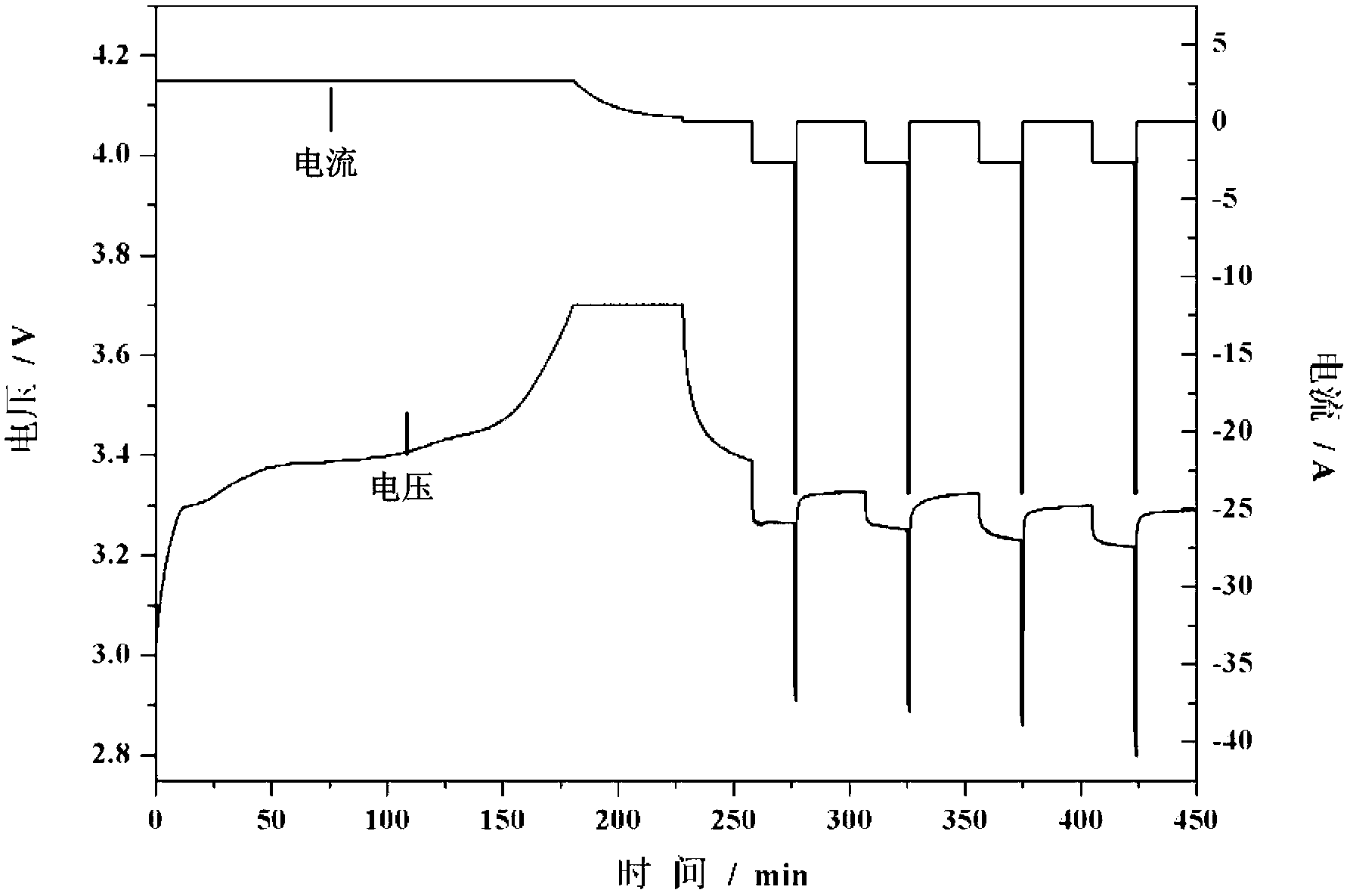

[0028] First select the simulated working condition: the charging and discharging simulated working condition adopts the simple simulated working condition proposed in the national standard "QC / T743-2006 Li-ion battery for electric vehicles". 3 (A) Constant current charging until the battery voltage reaches 3.7V, then switch to constant voltage charging, and charge until the current is close to 0.1I 3 Stop charging when the time is up, and discharge under simulated working conditions after standing still for 30 minutes. The specific discharge steps are shown in the table below.

[0029] Simple simulation of charging and discharging stages

[0030]

[0031] Detect lithium-ion power battery: detect and draw the discharge voltage characteristic curve of lithium-ion power battery under simulated wor...

Embodiment 2

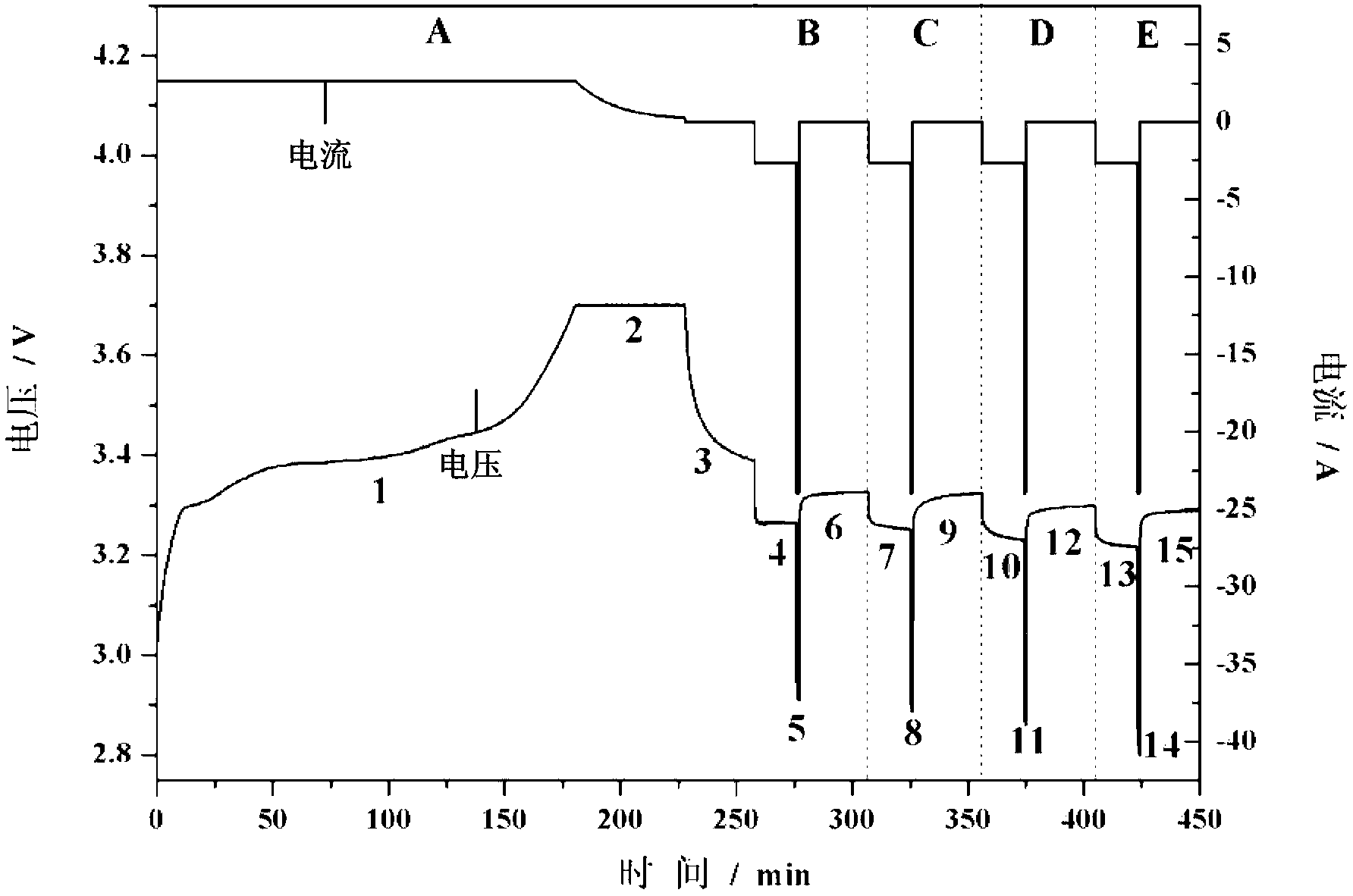

[0046]With the method of embodiment 1, the capacity range of the selected battery g, h, i, j is 8790-8810mAh, and its charge and discharge characteristic curve is input into the computer, and the charge and discharge characteristic curve of the battery g is selected as the reference curve, and the constant voltage charging middle The current deviation range at time 2 is ±50mA; the middle moments of each 1I3 discharge stage at 1, 4, 7, 10, and 13 o'clock in the constant current charging stage and the simulated working condition discharge process, and the middle moments of the resting stage at 3, 6, and 9 , 12, and 15 points, the voltage deviation range is ±20mV; the voltage deviation at 5, 8, 11, and 14 points in the middle of each 9I3 discharge stage during the simulated working condition discharge process is ±50mV, such as Figure 5 As shown, the upper limit of voltage I, the lower limit of voltage II, the upper limit of current III, the lower limit of current IV and the refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com