Diluting type slurry tank and slurry tower stirrer

A technology of agitator and slurry tank, which is applied in the field of dilution type slurry tank slurry tower agitator, which can solve the problems of poor dilution and mixing effect, insufficient dilution, large flow loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

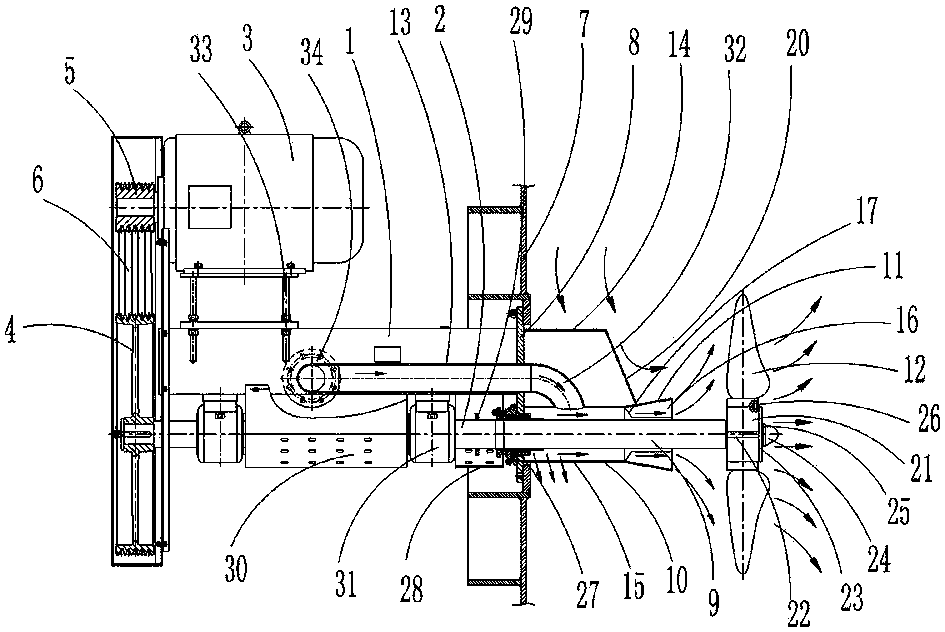

[0019] Embodiment 1: as figure 1 and figure 2 As shown, a dilution type slurry tank pulp tower agitator includes a base 1, a main shaft 2 is arranged in the base 1, a motor 3 is provided on the base 1, and the tail of the main shaft 2 A large pulley 4 is provided, and a small pulley 5 is provided on the motor 3. The small pulley 5 and the large pulley 4 are connected by a triangular tape 6. The motor 3 drives the main shaft 2 to rotate, and also includes a paddle Tower 7, the slurry tower 7 is fixedly connected with the base 1 through a connecting flange 8, the stirring section 9 at the head of the main shaft 2 in the base 1 extends into the slurry tower 7, and the stirring section 9 The outer jacket has a core dilution straight pipe 10 fixed to the inner wall of the slurry tower 7. The head of the core dilution straight pipe 10 is provided with a core liquid outlet reducer 11, and the head of the main shaft 2 is covered with Paddle 12, the base 1 is provided with an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com