Manufacturing technology of glass pot cover

A production process and technology for glass pots, which are applied in the directions of cooking utensils lids, etc., can solve the problems of low productivity, low yield, and inability to ensure seamless contact between the insert ring and tempered glass, and achieve low production cost, high yield, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

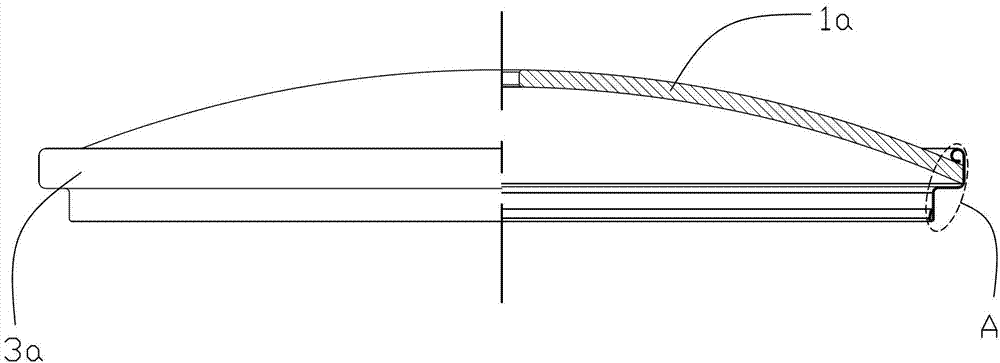

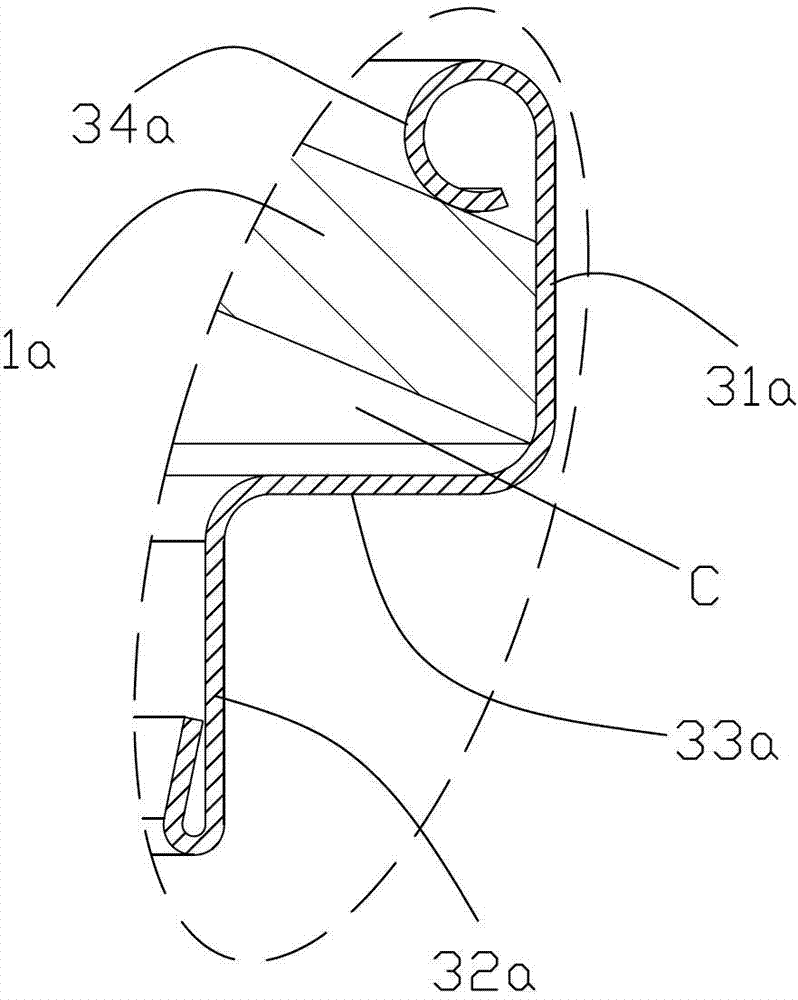

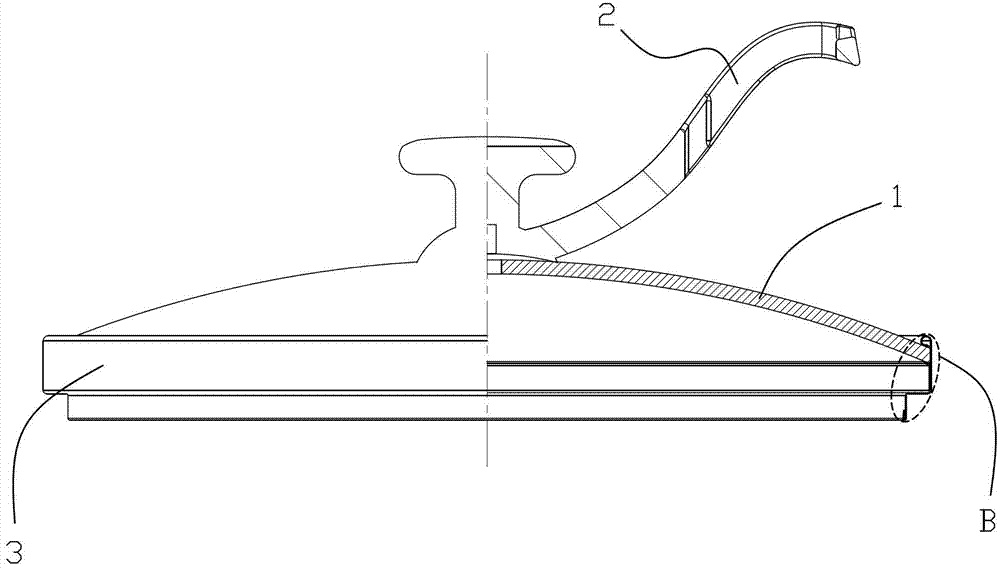

[0040] refer to Figure 3~Figure 11 , the manufacturing process of a kind of glass pot cover of the present invention, it comprises the following steps: , prepare the main steel ring 3 and tempered glass 1 that glass pot cover is used; The preparation technology of main steel ring 3 is preferably as follows:

[0041] (1) Cutting: Use cutting and cutting machine to obtain the steel strip with vertical knife edge; compared with the traditional energy storage welding machine that welds the two ends of the overlapping steel strip, it has less requirements on the end of the steel strip after blanking High, and laser welding is to butt the two ends of the steel strip, so the flatness of the welding joint is high when cutting the material, and the incision must be vertical, so the cutting and blanking machine is used to obtain the main steel ring steel strip;

[0042] (2) Laser welding: buckle the two ends of the steel strip with the buckle plate of the welding workbench, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com