Organic EL element and organic light-emitting device

An organic and component technology, applied in the direction of light-emitting materials, organic dyes, electrical components, etc., can solve problems such as difficult to describe, unable to obtain sufficient hole buffering effect, etc., to suppress the increase of voltage, difficult to voltage, and long driving life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0381] The present invention will be described more concretely by way of examples, but the present invention is not limited to the description of the following examples within the range not exceeding the gist.

[0382] It should be noted that Examples 1 to 3 correspond to the organic EL element A of the present invention or the organic EL element B of the present invention, and Example 4 corresponds to the organic EL element C of the present invention. In addition, Example 5 corresponds to the organic EL element B of the present invention. The organic EL element D.

reference example 1

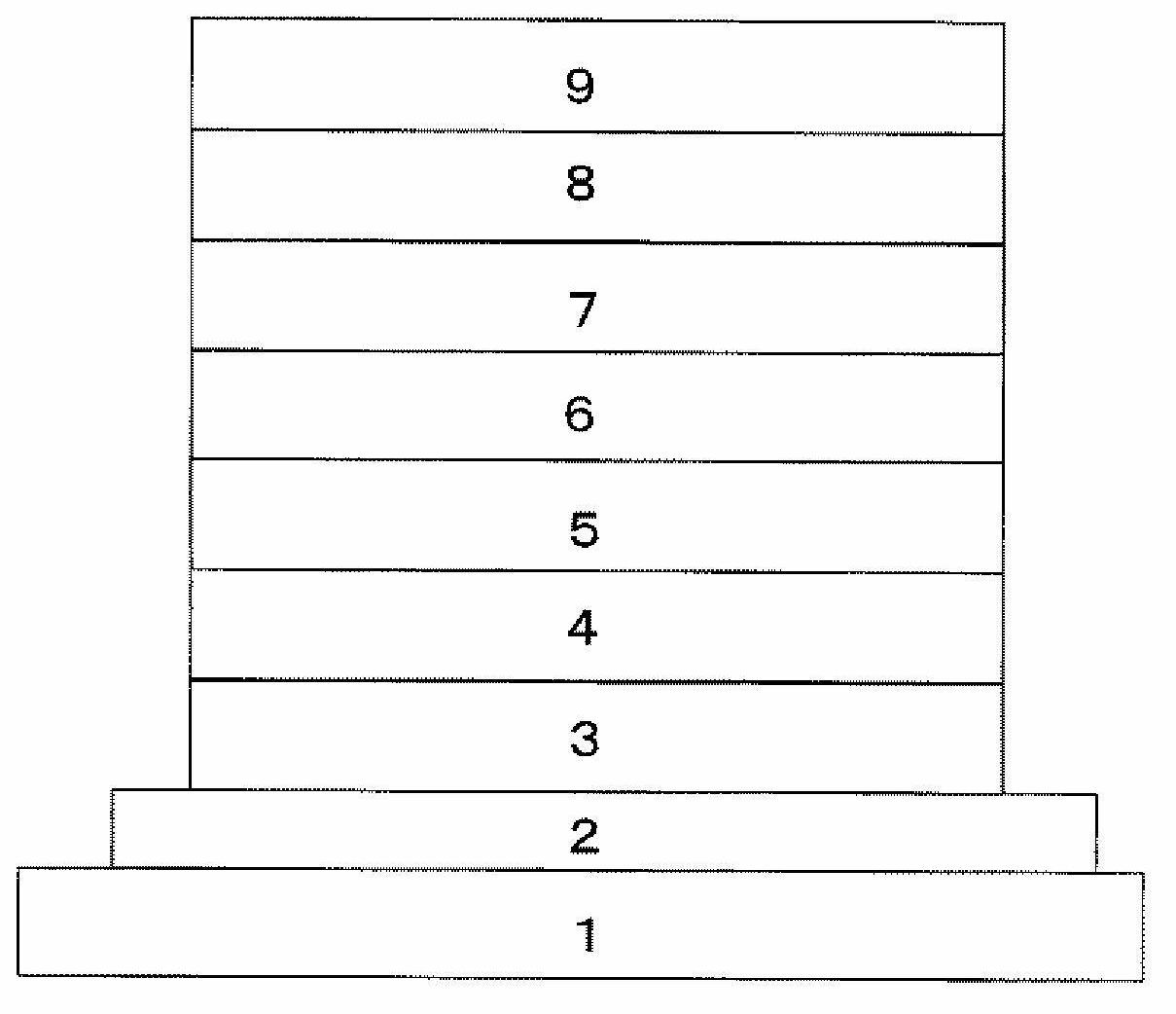

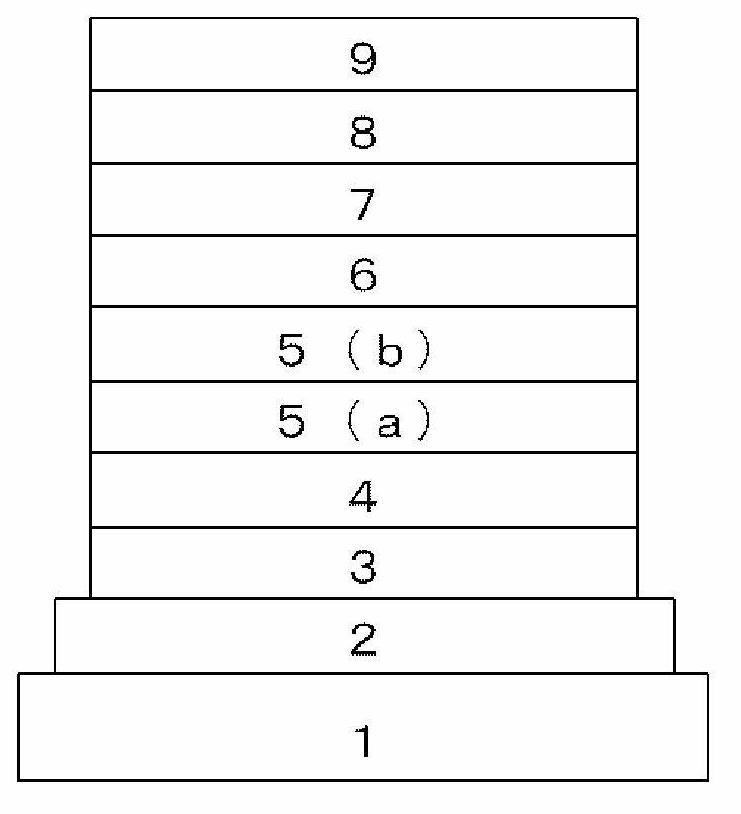

[0384] By the following method to produce a figure 1 An organic EL element of the structure shown.

[0385] (Production of ITO substrate)

[0386] A 150nm indium tin oxide (ITO) transparent conductive film (sputtered film-formed product; sheet resistance 15Ω) was deposited on a glass substrate 1, and patterned into a 2mm wide film using a common photolithography technique and hydrochloric acid etching method. stripes, thereby forming the anode 2.

[0387] (pre-processing)

[0388] The substrate (ITO substrate) on which the anode was patterned as described above was cleaned in the order of ultrasonic cleaning with a surfactant, water washing with pure water, and ultrasonic cleaning with isopropanol, and then it was blown with compressed air. Dry and finally, perform a 1 min UV ozone wash.

[0389] (Film formation of hole injection layer)

[0390] Next, the hole injection layer 3 was formed by a wet film-forming method as follows. 2% by weight of a polymer having a repeat...

reference example 2

[0416] An organic EL element was fabricated in the same manner as in Reference Example 1 except that the hole buffer material HA-1 in Reference Example 1 was changed to BAlq as a hole blocking material shown below.

[0417]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com