Multilayer growth by gas phase deposition

A gas phase and coating technology, applied in coatings, electrical components, gaseous chemical plating, etc., can solve problems such as hazards and hindering coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

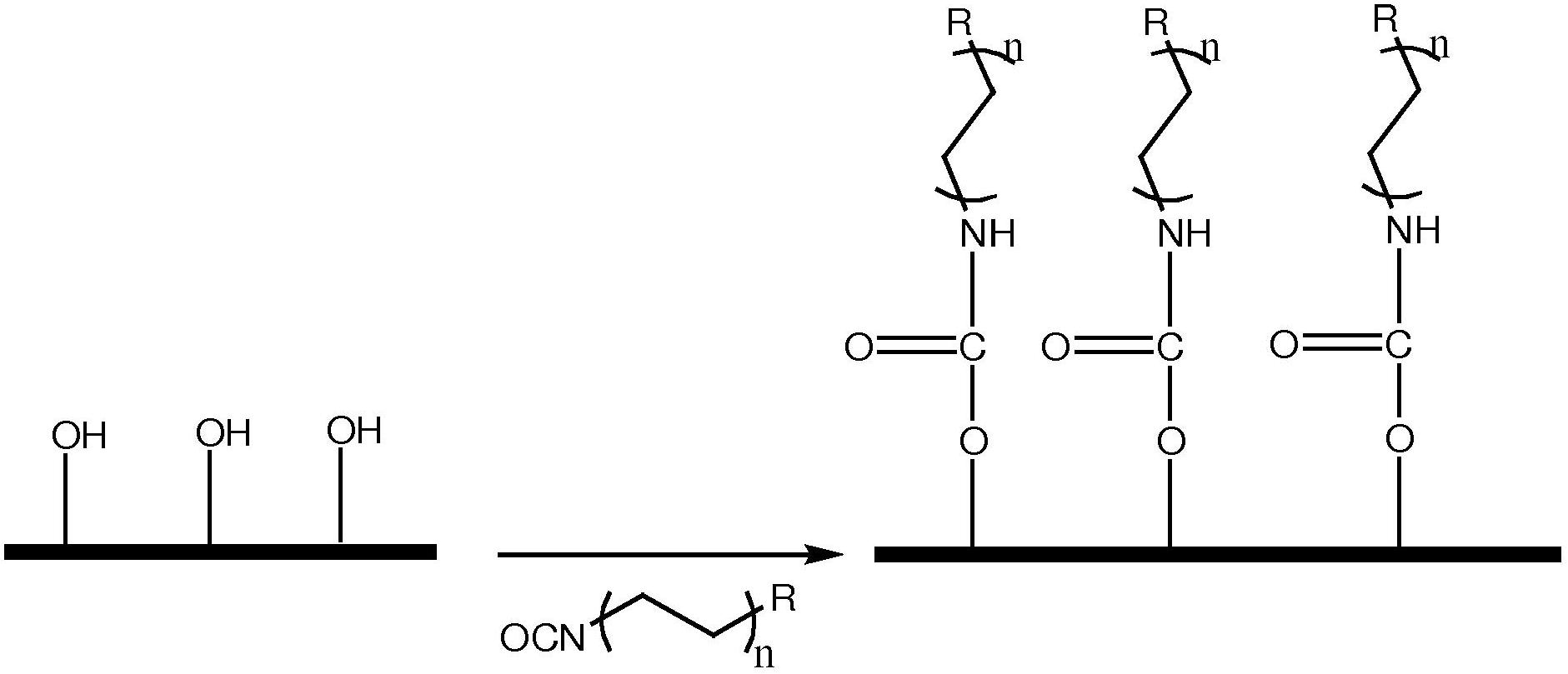

[0041] exist figure 1 An example of application of Chemical A to start application of a multi-layer system is shown in . Substrates with -OH reactive sites react with isocyanates.

[0042] R can be a carbon chain where n is 1 to 30, R is a charged species for cation / anion chromatography, or isocyanate or thioisocyanate.

Embodiment 2

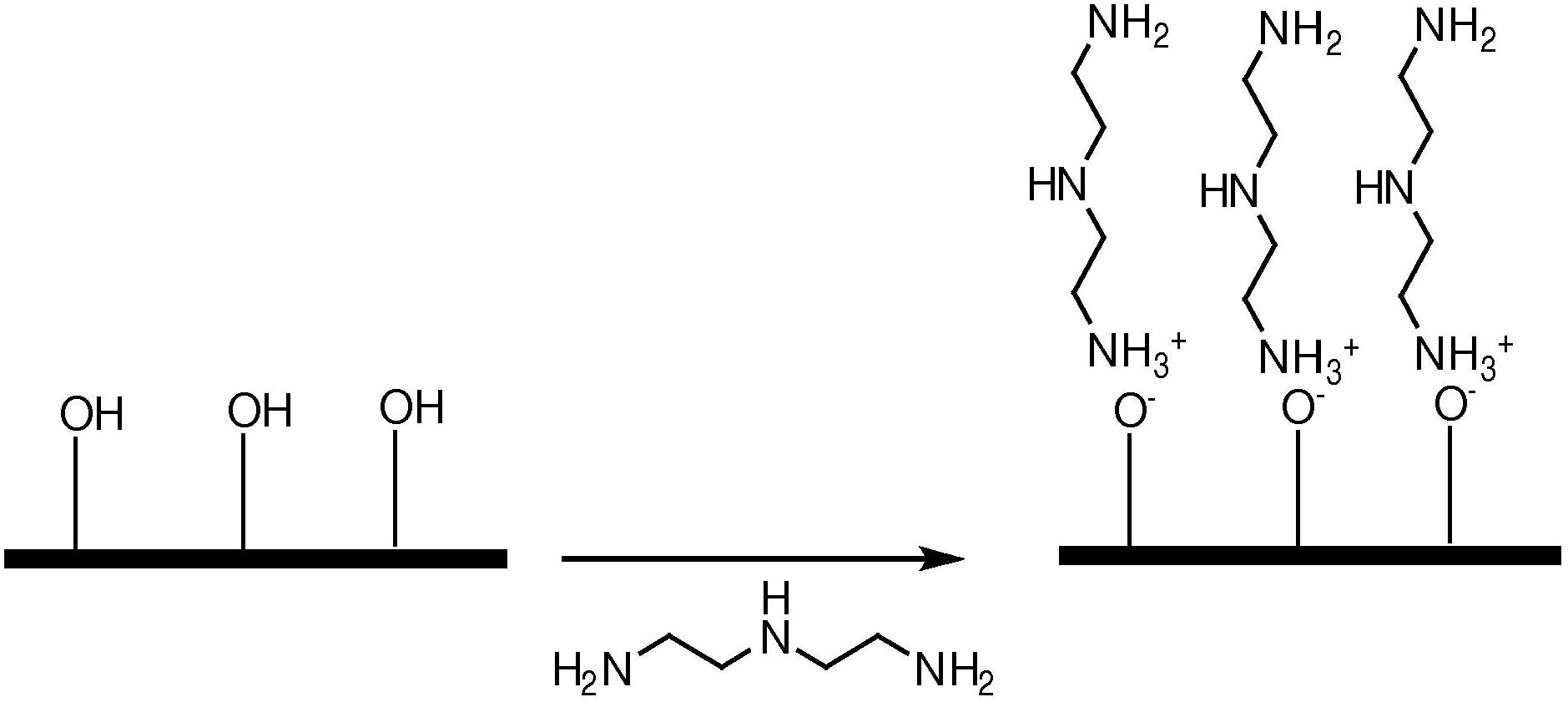

[0044] exist figure 2Another example of applying chemical A to form a multilayer system is shown in , where chemical A is a triamine. Since surface alcohols are acidic, they can form ionic bonds with triamines. In addition, the free amine——NH 2 Functional groups - can react with chemicals such as those with isocyanato groups to create bonded and cross-linked layers.

Embodiment 3

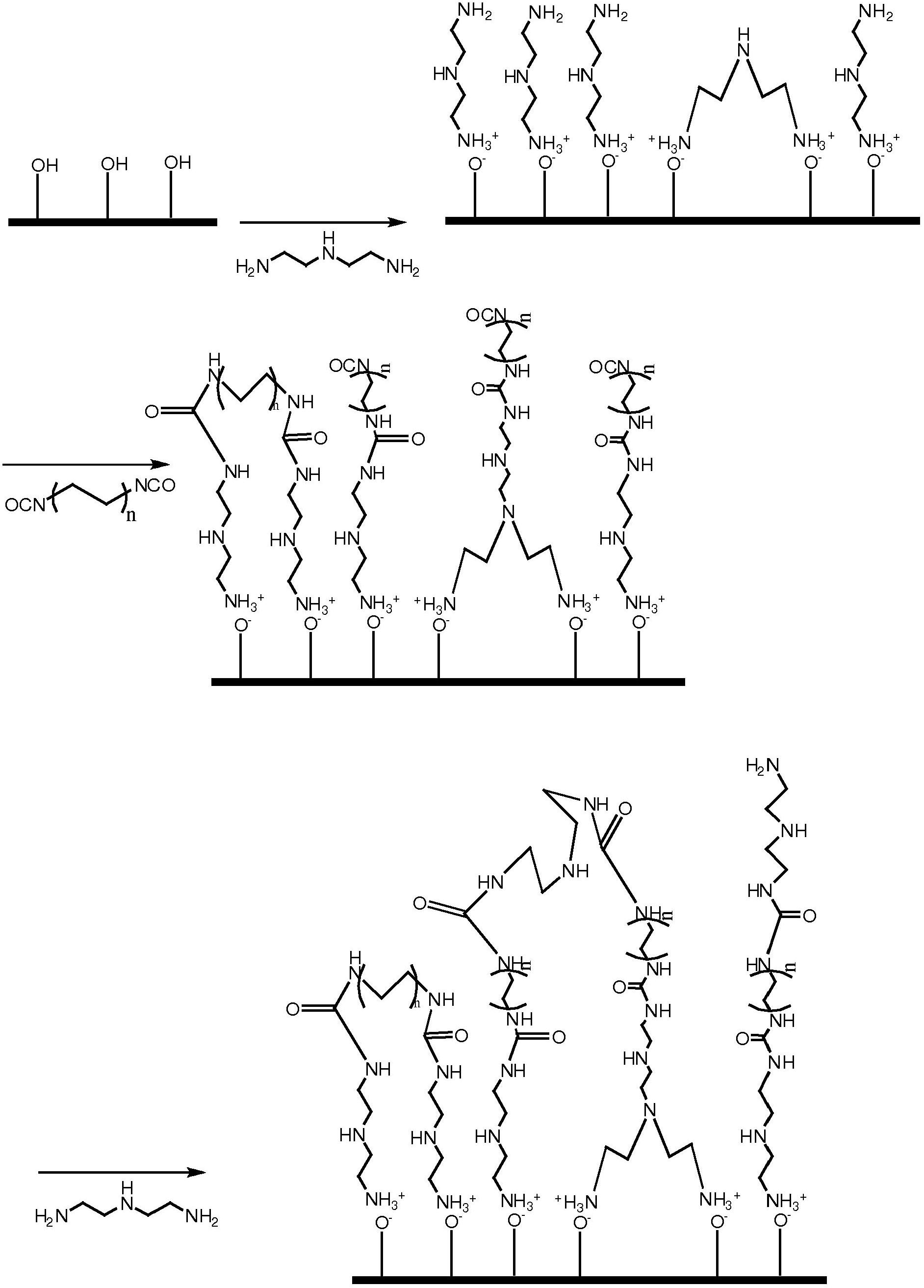

[0046] An amino terminated monolayer as in Example 2 can be reacted with Chemical B, an isocyanate, to produce a crosslinked material that will be stable under acidic conditions. Apply a monolayer and react like Figure 3A shown. The AB multilayer is then reacted with a triamine (same as chemical A), which is then reacted with chemical C with terminal reactive groups, as in Figure 3B shown.

[0047] The multilayer system can be characterized as ABCD, where C=A, where A=triamine, B=diisocyanate, D=monoisocyanate or monoepoxide with an alkyl chain length of 2-30 carbon units. This method produces highly crosslinked stationary phases, which can be attributed to diisocyanates or triamines. In addition, A and B layers can be similarly applied to form AB) n CD or (AB) n C multi-layer system, wherein n is 2 or more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com