Method for cleaning waste silicon material generated in silicon wafer treatment process

A processing process and technology of silicon material, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of incomplete cleaning of waste silicon material, low work efficiency, etc., so as to improve work efficiency and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

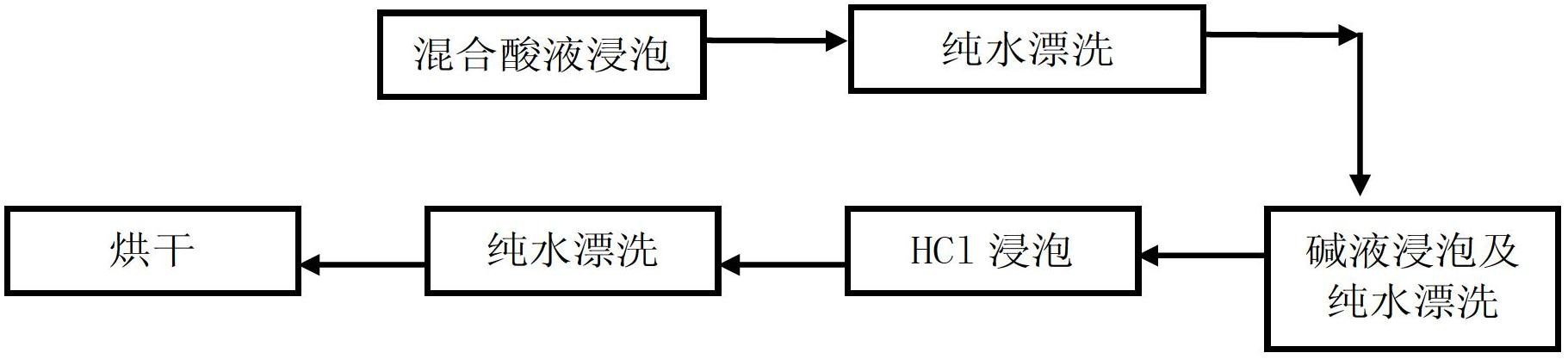

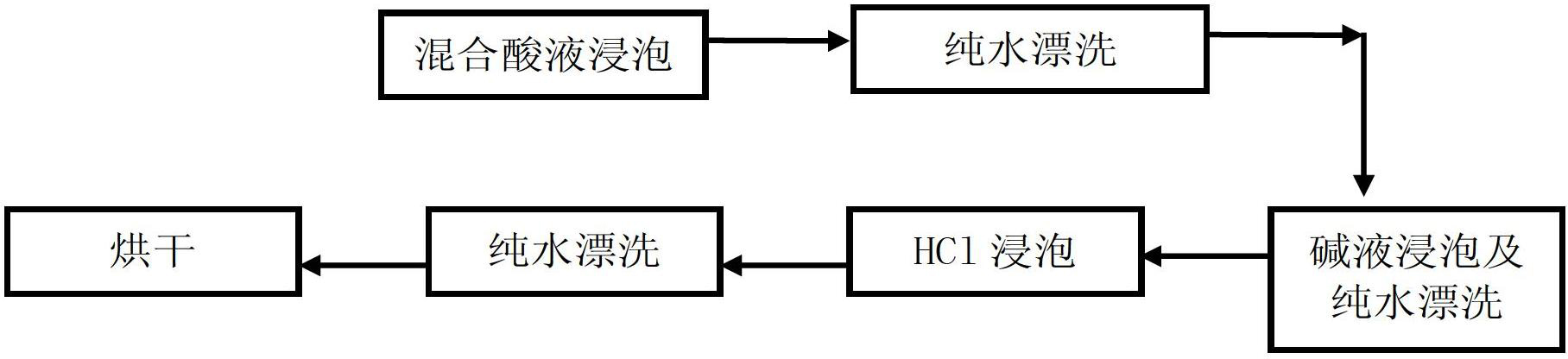

[0026] The specific process is as figure 1 Shown:

[0027] 1) Soak the waste silicon material in a mixed acid solution with a mass percentage of 5% for 15 minutes, then put the waste silicon material into circulating pure water with a conductivity of 14-16 trillion and rinse it with ultrasonic waves for 15 minutes; 2) Soak the waste silicon material soaked in the mixed acid solution in 15wt% NaOH solution, soak for 5 minutes at 80°C, and then put the waste silicon material into circulating pure water with a conductivity of 14~16M and use ultrasonic waves Rinse for 5 minutes; 3) Soak the waste silicon material in 5wt% HCl solution for 10 minutes, then rinse with pure water and dry, wherein the mixed acid solution is the acid solution discarded during the battery preparation process.

[0028] After inspection, the impurities and oxide layer on the waste silicon material were cleaned, and the surface loss was controlled at 10-20 microns.

Embodiment 2

[0030] 1) Soak the waste silicon material in a mixed acid solution with a mass percentage of 5% for 10 minutes, then put the waste silicon material into circulating pure water with a conductivity of 14-16 trillion and rinse it with ultrasonic waves for 10 minutes; 2) Soak the waste silicon material soaked in the mixed acid solution in 25wt% NaOH solution, soak for 10 minutes at 80°C, and then put the waste silicon material into circulating pure water with a conductivity of 14-16 megabytes for ultrasonic treatment. Rinse for 10 minutes; 4) Soak the waste silicon material in 15wt% HCl solution for 5 minutes, then rinse with pure water and dry, wherein the mixed acid solution is the acid solution discarded during the battery preparation process.

[0031] After inspection, the impurities and oxide layer on the waste silicon material were cleaned, and the surface loss was controlled at 10-20 microns.

[0032] In summary, the present invention can reduce the labor intensity of worke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com