Organic electroluminescence display device and manufacturing method thereof

A technology for electroluminescence display and organic light-emitting layer, which is applied in the manufacture of semiconductor/solid-state devices, circuits, electrical components, etc., can solve the problems of difficult to control film thickness, difficult to manufacture, etc., and achieves reduced characteristic dispersion and easy film thickness control. , the effect of easy stabilization characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0056] (Organic EL display device in which a second organic light-emitting layer of another color is formed by coating method)

no. 2 approach

[0058](Organic EL display device in which a second organic light-emitting layer of another color is formed by vapor deposition method)

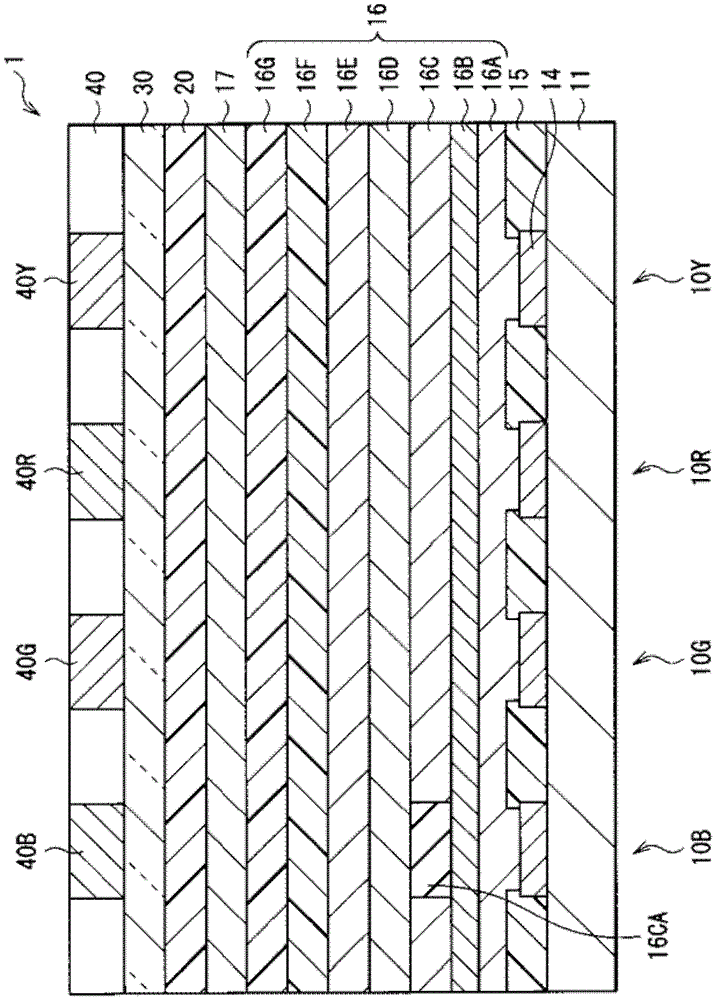

[0059] (first embodiment)

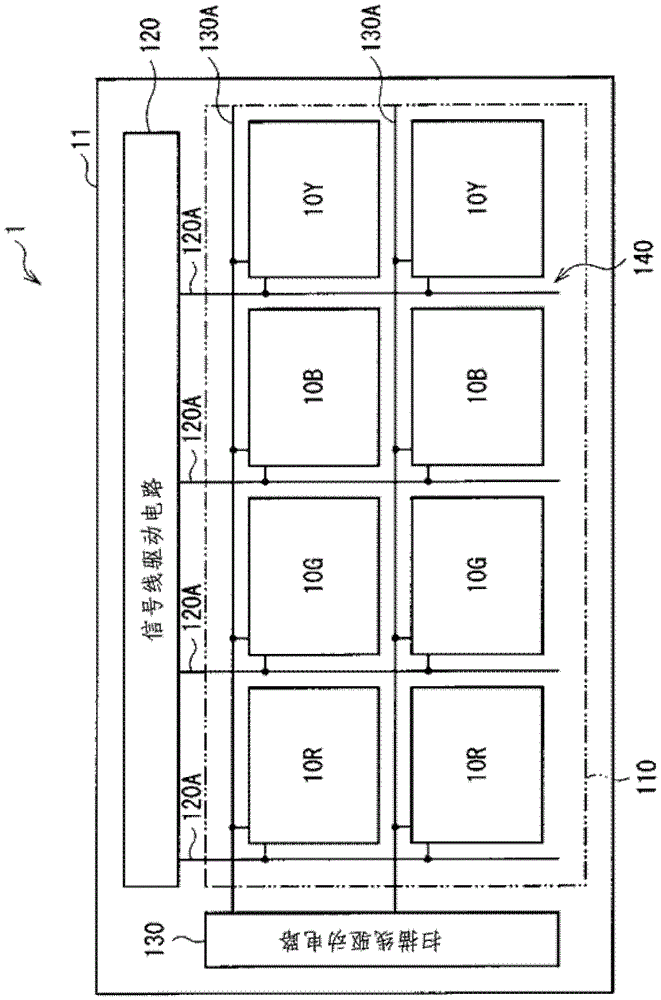

[0060] figure 1 The structure of the organic EL display device according to the first embodiment of the present invention is shown. The organic EL display device 1 is used in an organic EL television or the like, in which, for example, a plurality of red organic EL elements 10R, green organic EL elements 10G, blue organic EL elements 10B, and yellow organic EL elements 10Y to be described later are arranged in a matrix The form is arranged in the display area 110 on the substrate 11 . Around the display area 110, a signal line driver circuit 120 and a scan line driver circuit 130 are provided as drivers for screen display.

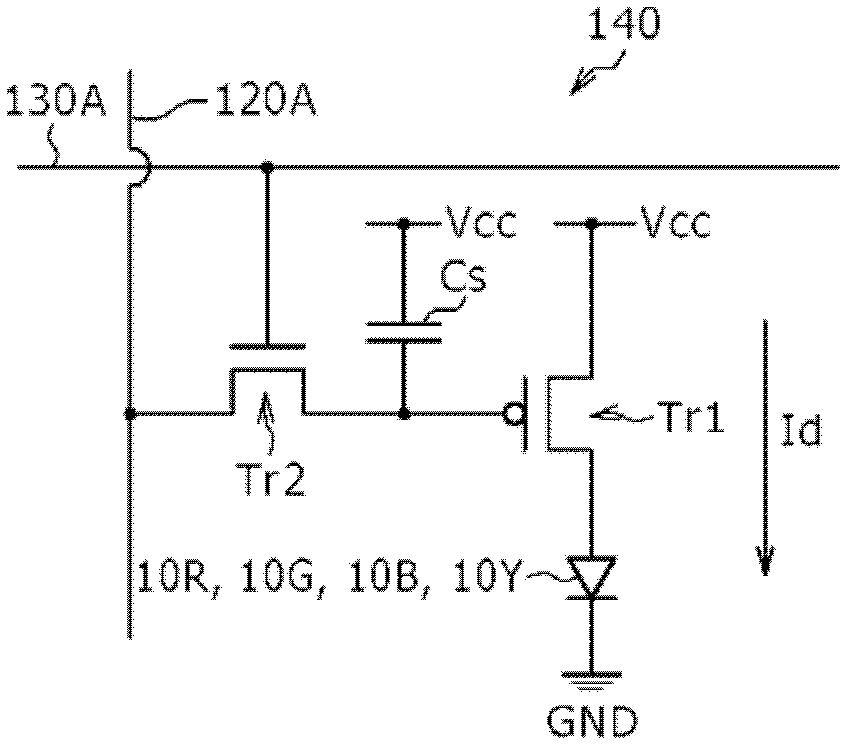

[0061] A pixel drive circuit 140 is provided in the display area 110 . figure 2 An example of the pixel driving circuit 140 is shown. The pixel driving circuit 140 is an active type drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com