High-heat conducting high-air permeability less-glue mica tape and preparing method thereof

A technology of less rubber mica tape and high thermal conductivity, which is applied in the direction of electrical components, insulators, insulators, etc., can solve the problems affecting the high air permeability of mica tape, achieve good adhesion, improve thermal conductivity, and good softness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

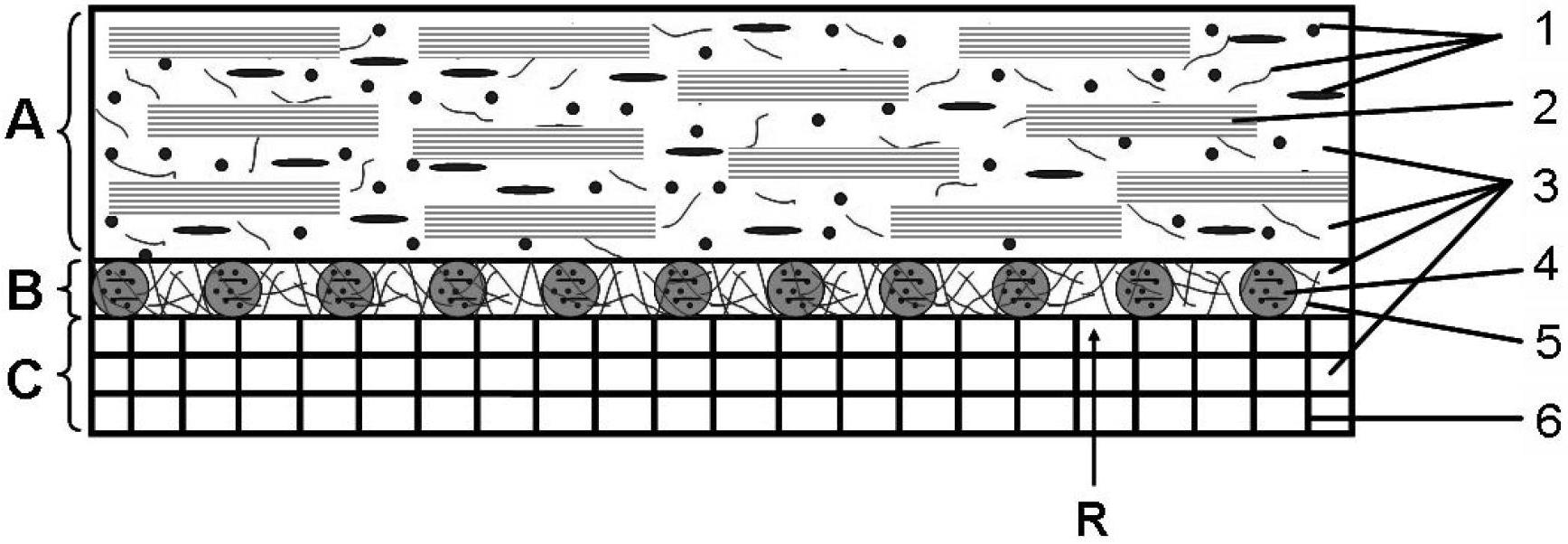

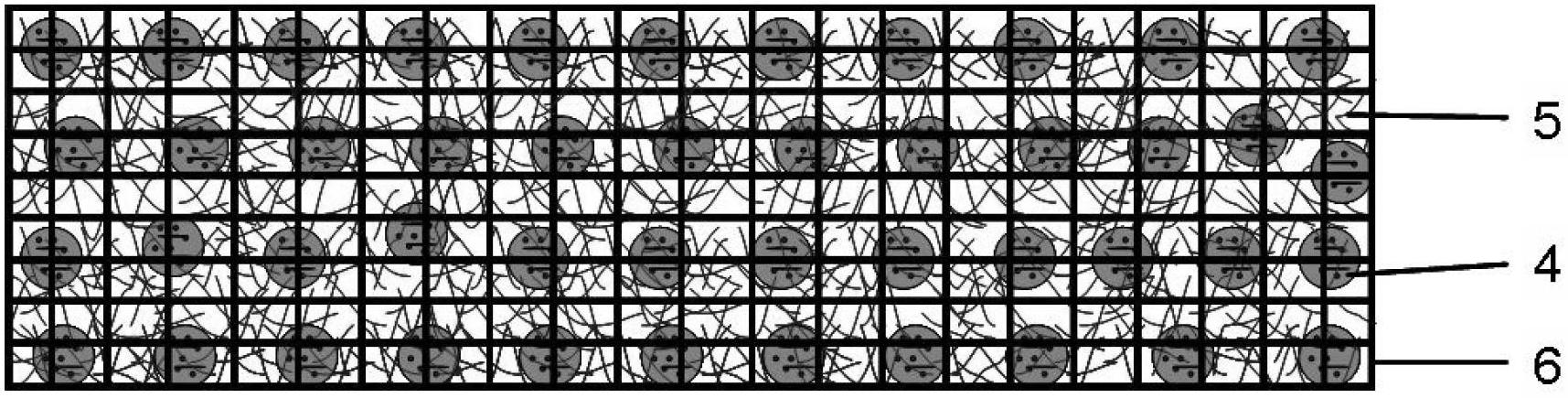

[0046] This embodiment provides a mica tape with high thermal conductivity, high air permeability and less glue. Such as figure 1 and 2 As shown, the high thermal conductivity and high air permeability mica tape with less glue includes a mica paper layer A, a reinforcing material layer C, and a resin adhesive layer B between the mica paper layer A and the reinforcing material layer C. The resin adhesive layer B includes the resin adhesive 4 evenly distributed on the interface of the mica paper layer A and the reinforcing material layer C in dots. The mica paper layer A is composed of mica paper, wherein the mica paper is made by adding high thermal conductivity inorganic particles and / or high thermal conductivity inorganic fibers 1 with a weight fraction of 2% to 30% into the non-calcined muscovite flakes 2, and making pulp, The thickness of mica paper is 0.1-0.2mm, and the mass per unit area is 80-220g / m 2 . The reinforcing material layer C is composed of a fiber cloth 6 ...

Embodiment 2

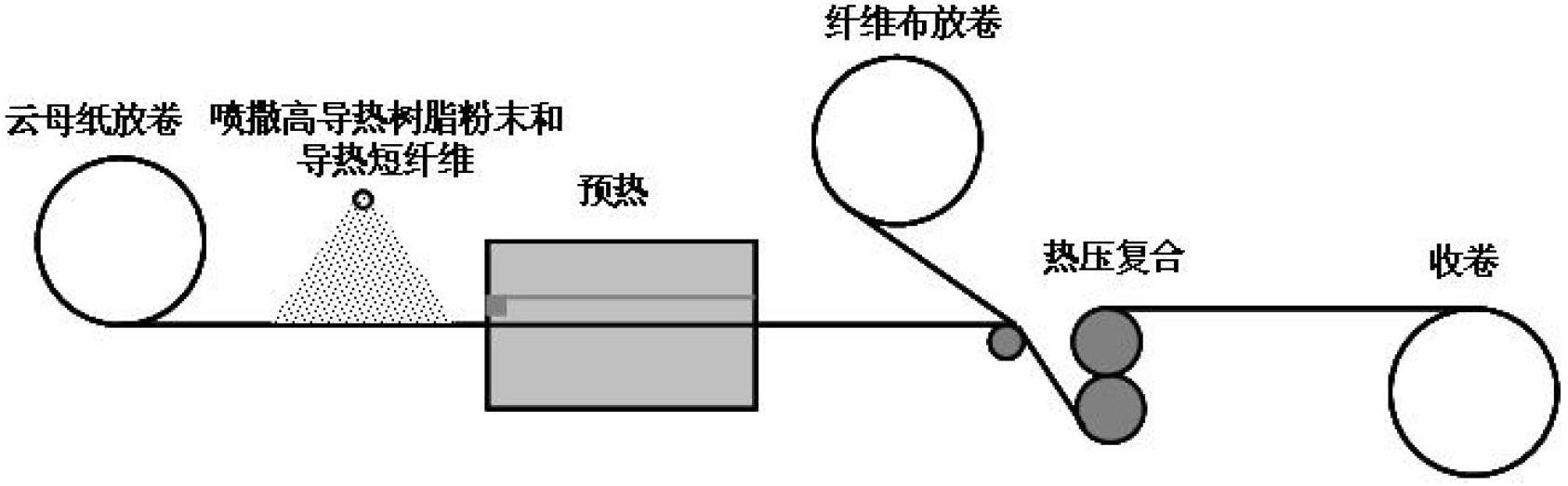

[0057] This embodiment provides a kind of mica tape with high thermal conductivity and high air permeability and less glue, its structure is the same as that of embodiment 1, and according to image 3 The procedure shown was prepared. Concrete preparation steps are as follows:

[0058] (1), preparation of high thermal conductivity resin powder: epoxy powder resin with epoxy equivalent of 1490g / equivalent and boron nitride inorganic particles with a mass fraction of 52% and a particle size of 20-80 μm and a mass fraction of 20%, After the silicon nitride micropowder with a particle size of 200nm~5μm is mixed evenly, it is extruded and granulated by a twin-screw extruder, crushed at minus 40°C and sieved to obtain a thermal conductivity of 1.15W / m*K, and a particle size of 90-120 mesh, high thermal conductivity resin powder with a melting temperature of 145°C.

[0059] (2) Mica paper unwinding, wherein: mica paper is non-calcined muscovite paper, and its air permeability is 18...

Embodiment 3

[0065] The present embodiment provides a kind of preparation method of high thermal conductivity and high air permeability less rubber mica tape, which according to image 3 The process shown is carried out, specifically including the following steps:

[0066] (1), preparation of high thermal conductivity resin powder: epoxy powder resin with epoxy equivalent of 2150g / equivalent and boron nitride inorganic particles with a mass fraction of 51% and a particle size of 20-80 μm and a mass fraction of 23%, After the silicon nitride micropowder with a particle size of 500nm~5μm is mixed evenly, it is extruded and granulated by a twin-screw extruder, crushed at minus 40°C and sieved to obtain a thermal conductivity of 1.08W / m*K, and a particle size of 100-150 mesh, high thermal conductivity resin powder with a melting temperature of 147°C.

[0067] (2) Mica paper unwinding, wherein: mica paper is non-calcined muscovite paper, and its air permeability is 185s / 100cm 3 , the thermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com