Tailoring device for acoustic materials of impedance tube test

A technology of acoustic materials and cutting devices, applied in the direction of sampling devices, etc., to achieve the effects of reducing errors, improving accuracy, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

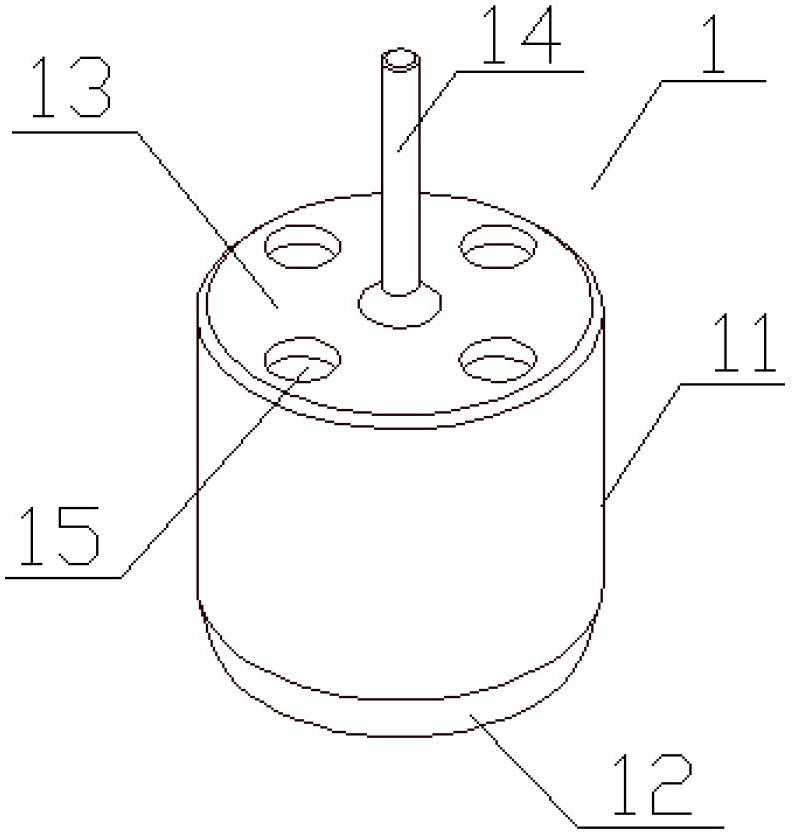

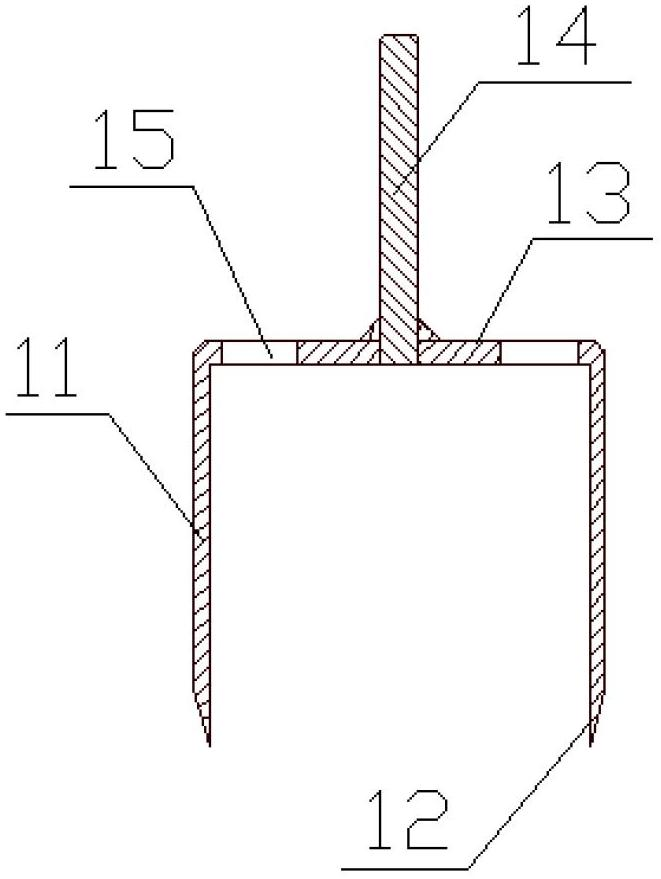

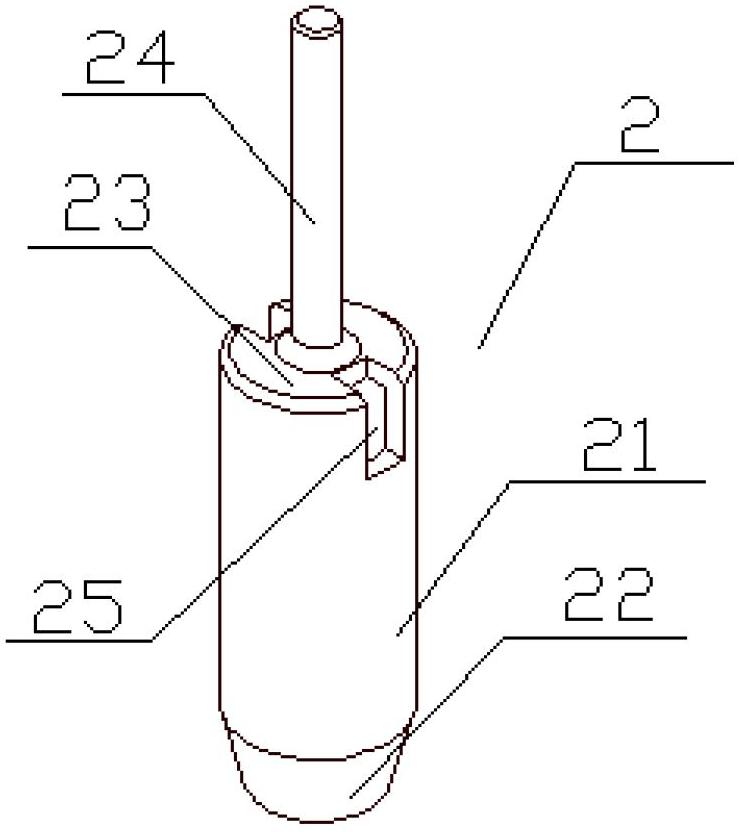

[0020] Embodiment 1: An acoustic material cutting device for an impedance tube test, including a first cutting mechanism and a second cutting mechanism, the first cutting mechanism includes a first cutting tool 1, and the first cutting tool 1 includes an integrally connected tubular first A cutter head 11 and an annular first blade 12, the inner diameter of the first blade 12 is 100mm, the first cutter head 11 is integrally provided with a circular first cover plate 13, the central axis of the first cover plate 13 Fixedly provided with the first connecting rod 14 for connecting the drilling machine, at least one through hole 15 is also provided on the first cover plate 13, the second cutting mechanism includes the second cutting tool 2, and the second cutting tool 2 includes an integrally connected The tubular second cutter head 21 and the annular second blade 22, the inner diameter of the second blade 22 is 29mm, the second cutter head 21 is integrally provided with a circular...

Embodiment 2

[0023] Embodiment 2: An acoustic material cutting device for an impedance tube test, including a first cutting mechanism and a second cutting mechanism, the first cutting mechanism includes a first cutting tool 1, and the first cutting tool 1 includes an integrally connected tubular first A cutter head 11 and an annular first blade 12, the inner diameter of the first blade 12 is 100mm, the first cutter head 11 is integrally provided with a circular first cover plate 13, the central axis of the first cover plate 13 Fixedly provided with the first connecting rod 14 for connecting the drilling machine, at least one through hole 15 is also provided on the first cover plate 13, the second cutting mechanism includes the second cutting tool 2, and the second cutting tool 2 includes an integrally connected The tubular second cutter head 21 and the annular second blade 22, the inner diameter of the second blade 22 is 29mm, the second cutter head 21 is integrally provided with a circular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com