LED lamp

A technology of LED lamps and light-transmitting lamps, which is applied in cooling/heating devices of lighting devices, lighting and heating equipment, electrical components, etc., which can solve problems such as short life, low luminous efficiency, and poor heat dissipation, and reduce junction temperature , good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

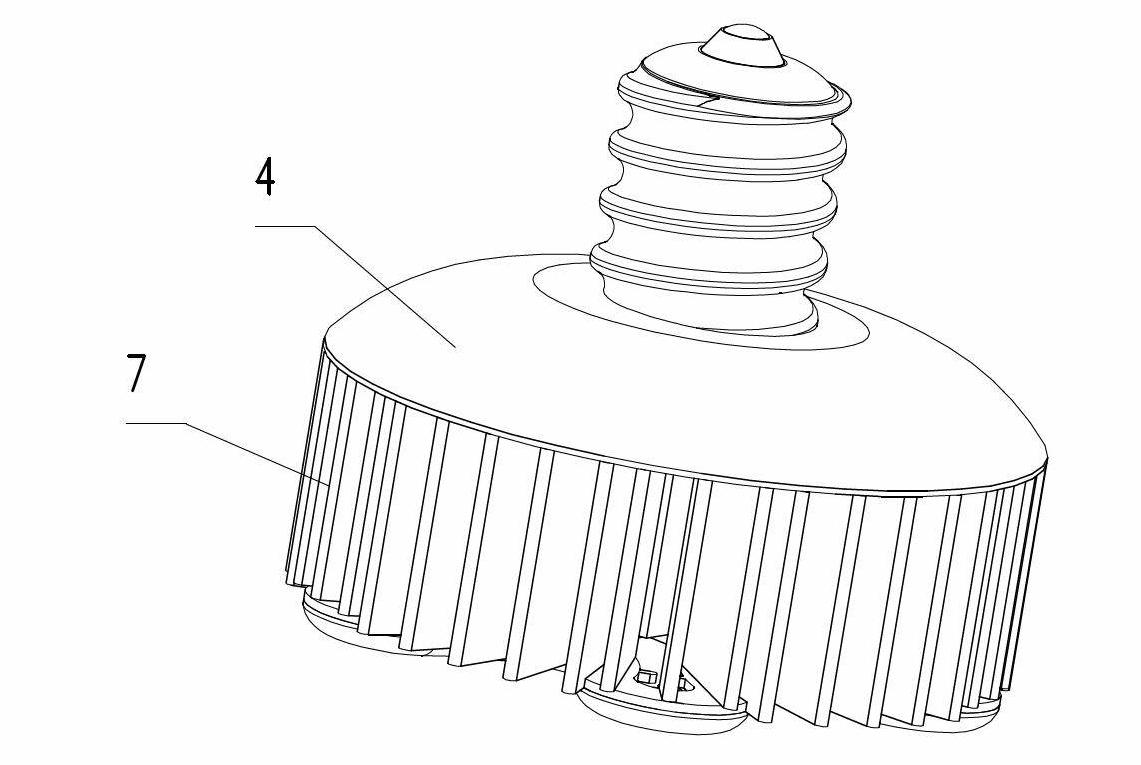

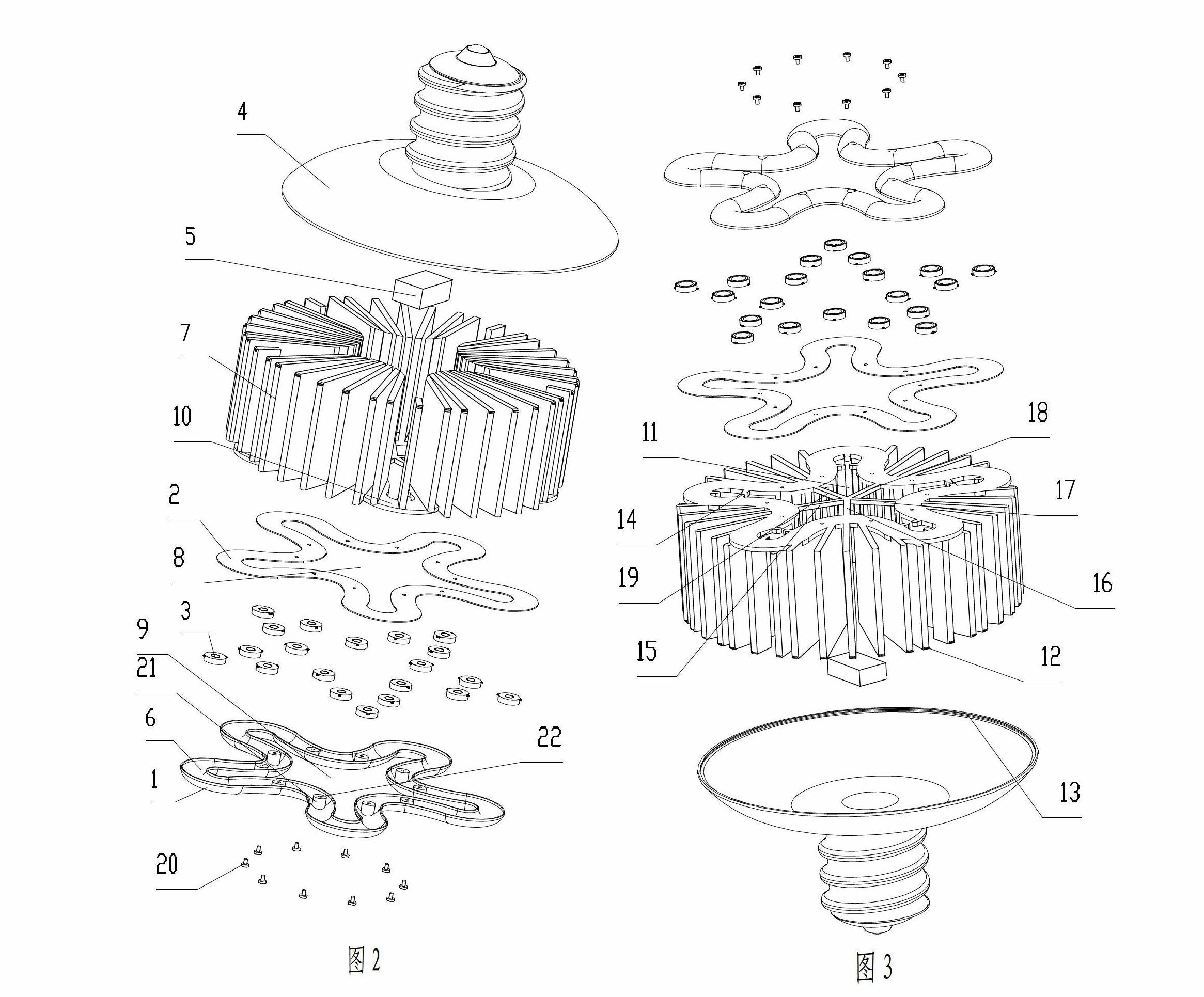

[0084] Such as figure 1 , figure 2 , image 3 As shown, an LED lamp includes a light-transmitting lamp cover 1, a heat-dissipating PCB board 2, a heat-dissipating seat 10, a plurality of LED lamp beads 3 containing only one LED chip, a lamp holder 4, and positive and negative electrodes electrically connected to the LED lamp beads 3. The conductive layer of the layout circuit of the pins (not shown), the electric control device 5 electrically connected with the external power supply and the LED light emitting unit. The electric control device 5 is fixed on the lamp cap 4 . The LED lamp beads 3 are arranged in a similar pentagonal shape, fixed on the heat dissipation PCB board 2, the conductive layer of the layout circuit is directly arranged on the heat dissipation PCB board 2, and the LED lamp beads 3 and the conductive layer of the layout circuit are arranged on the same side of the heat dissipation PCB board 2 face.

[0085] The outer peripheral shape of the heat sink ...

Embodiment 2

[0088] Such as Figure 4 As shown, an LED lamp includes a light-transmitting lamp cover 30, a plastic plate 37 forming a lens, a PCB board 31, a heat dissipation base 32, an LED light-emitting unit, and a layout circuit conductive layer (not shown) electrically connected to the LED light-emitting unit. output), an electric control device 34 and a lamp holder 35 electrically connected to the external power supply and the conductive layer of the layout circuit. The LED lighting unit includes an LED chip 36 , a lens 45 , and a gold wire 33 electrically connecting the LED chip 36 and the conductive layer of the layout circuit.

[0089] The heat dissipation base 32 includes an annular flat bottom plate, and a plurality of chip fixing bosses 40 protruding from the bottom plate integrally formed with the heat dissipation base 32 , and the fixing bosses 40 are all distributed on the same circumference. A fixing column 39 is extended on the end surface of the plastic plate 61 forming ...

Embodiment 3

[0096] Such as Figure 5 As shown, the difference from Embodiment 2 is that an LED lamp includes a light-transmitting lamp cover 60, a plastic plate 61 forming a lens, a PCB board 62, a heat dissipation base 63, a flow channel cover plate 64, an LED light-emitting unit, an electric The conductive layer of the layout circuit (not shown) that is connected to the LED light emitting unit, the electric control device 65 and the lamp holder 66 that are electrically connected to the external power supply and the conductive layer of the layout circuit. The LED light emitting units are arranged in a pentagon.

[0097] The peripheral shape of the runner cover plate 64 , the heat dissipation base 63 , the transparent lamp cover 60 , the PCB board 62 , and the plastic plate 61 forming the lens is a pentagon with a circular arc transition. An integrally formed cooling channel 76 is provided on the side of the heat dissipation base 63 away from the LED light emitting unit. The maximum out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com