Double clamping groove lining hoop

A technology of lining and slotting, which is applied in the direction of hose connection devices, mechanical equipment, pipes/pipe joints/fittings, etc., which can solve problems such as looseness, fluid/gas leakage in the pipe, bursting and sealing of the connected pipe, etc., and achieve reduction The force-bearing area, rapid construction, and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific structure of the present invention is further provided by the following embodiments in conjunction with the accompanying drawings.

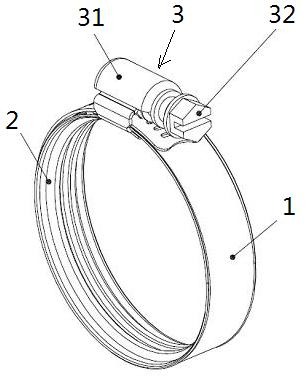

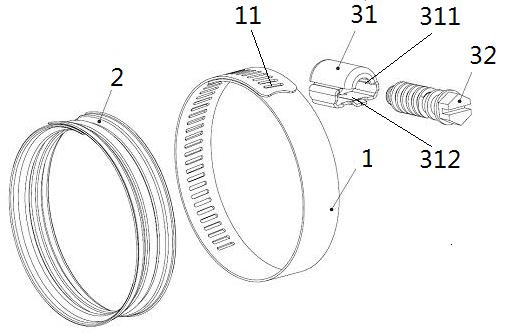

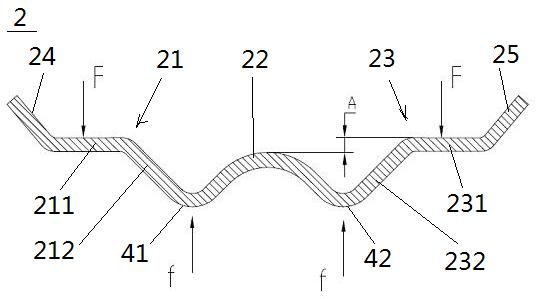

[0024] see Figure 1 ~ Figure 3 . The present invention is a double-slot liner clamp, which comprises a band 1 , a liner 2 and a locking component 3 attached to the inner wall of the band. The inner liner is a double card slot inner liner, including a first side 21, a second side 22 and a third side 23; the first side and the third side have the same structure and are arranged symmetrically. The first side 21 includes a transverse force receiving portion 211 and an inwardly inclined support portion 212 smoothly connected to one end of the transverse force receiving portion; the third side 23 includes a transverse force receiving portion 231 and an inwardly inclined support portion 232 smoothly connected to one end of the transverse force-receiving portion. The second side 22 is an arched part, and its two ends are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com