Continuous oil pipe sectional sand-blasting perforation casing fracturing pipe column and casing fracturing method

A technology of fracturing pipe strings and sandblasting perforation, which is applied in the direction of casing, drill pipe, earthwork drilling, etc., which can solve the problems of low construction efficiency, long construction period, and inability to meet large-scale fracturing, and achieve integrity Strong, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

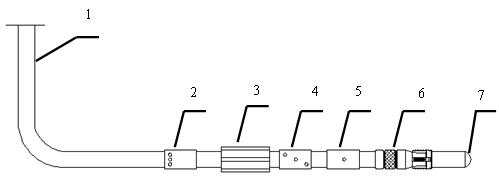

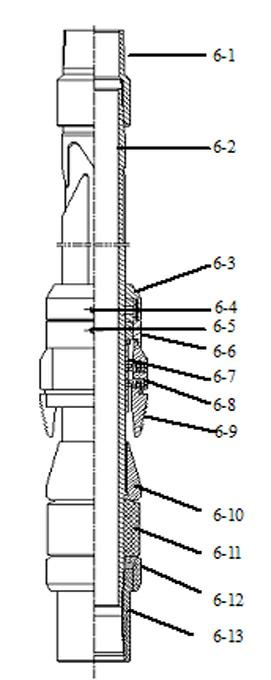

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings. see figure 1 with figure 2 A coiled tubing segmented sandblasting and perforating casing fracturing string includes a safety joint 2 connected to a coiled tubing 1, a centralizer 3, a hydraulic injection tool 4 and a reverse circulation valve 5, and the reverse circulation valve 5 The mechanical coiled tubing fracturing packer 6 is also connected below. The mechanical coiled tubing fracturing packer 6 includes a center pipe 6-2, a balanced rocking slip and a sealing mechanism. The center pipe 6-2 is provided with a setting track and an unsealing track that communicate with each other, and the balanced rocking slip The sealing mechanism is installed on the center pipe 6-2, and the two ends of the center pipe 6-2 are connected with the upper joint 6-1 and the lower joint 6-13. Balanced rocking slips include retaining ring 6-3, slip seat 6-6 and slip block 6-9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com