A kind of laminated nonwoven fabric and its device and production method

A technology of non-woven fabrics and laminating devices, which is applied in the direction of non-woven fabrics, textiles, and papermaking, can solve problems such as easy fluffing, and achieve the effects of reducing fluffing, increasing thickness, and reducing hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

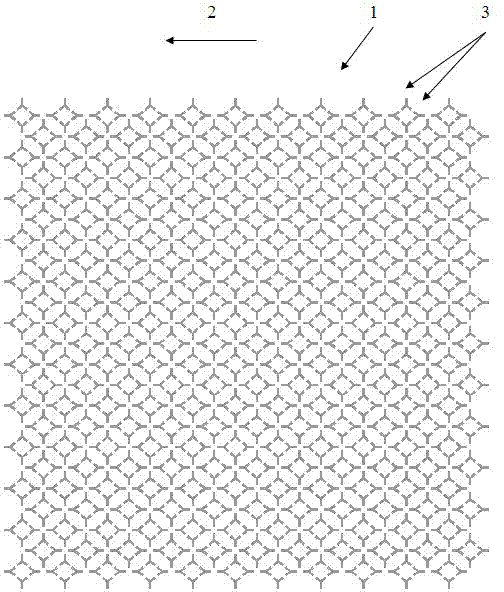

[0028] The nonwoven fabric 1 of the present invention is figure 1 It is shown in plan view. This pattern is just one example of the new method of making laminated nonwovens. In the formal production process, laminated non-woven fabrics with different appearance effects can be produced according to the pattern. exist figure 1 Among them, 2 represents the running direction of the device. Laminated nonwovens are produced in machine direction 2. The nonwoven fabric 1 forms two different pattern areas in the running direction of the device, namely the flower pattern formed by the concave-convex area 3 . If you look at the front and back sides respectively, the front raised parts form a surface, and the front concave parts become another surface with raised parts when viewed from the reverse side.

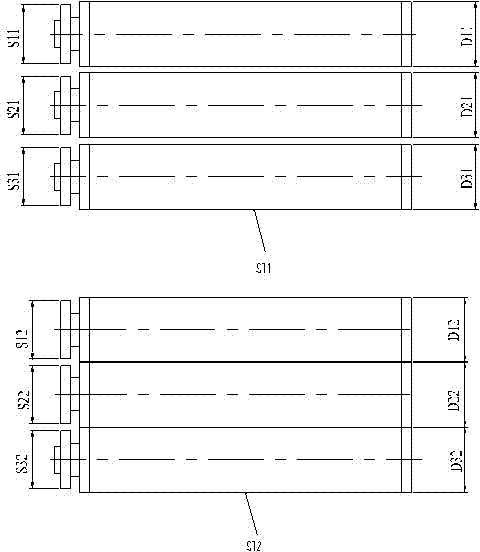

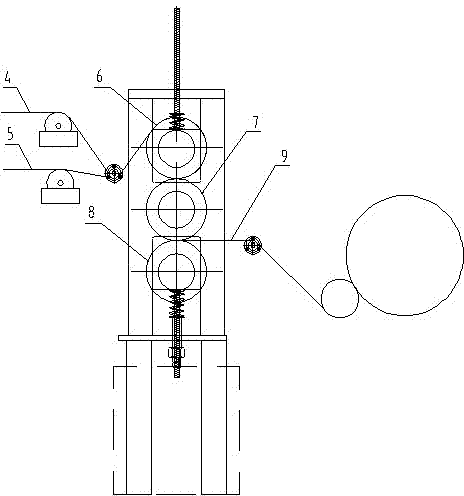

[0029] figure 2 A schematic diagram showin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com