Die cutting preparation method of reflection strip attached with shading adhesive

A technology of shading glue and reflective strips is applied in the field of die-cutting product manufacturing, which can solve the problems of high assembly cost and low yield, and achieve the effects of low assembly cost, improved production efficiency and yield, and improved degree of mechanization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

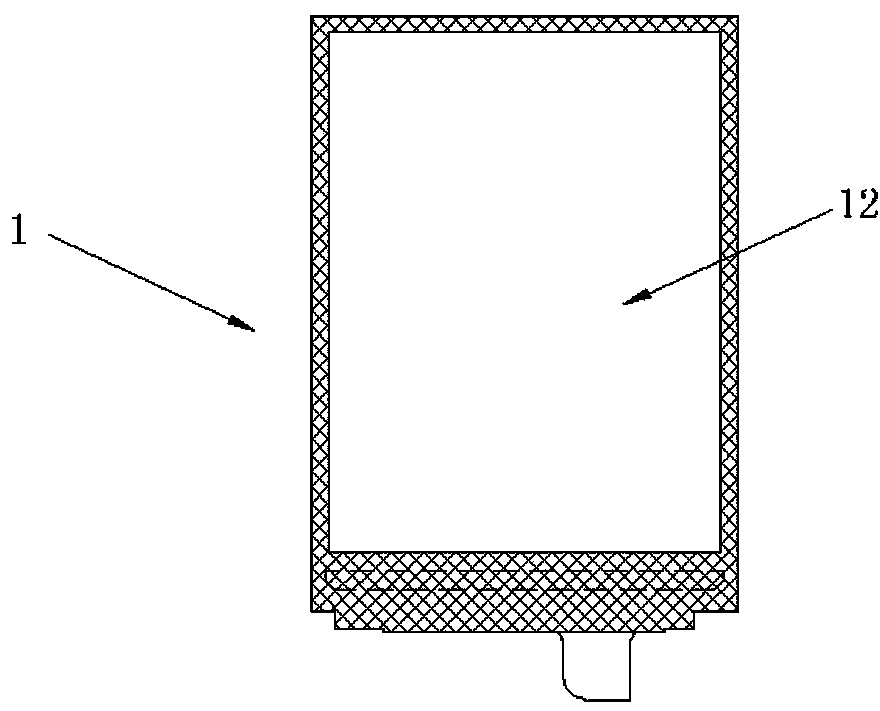

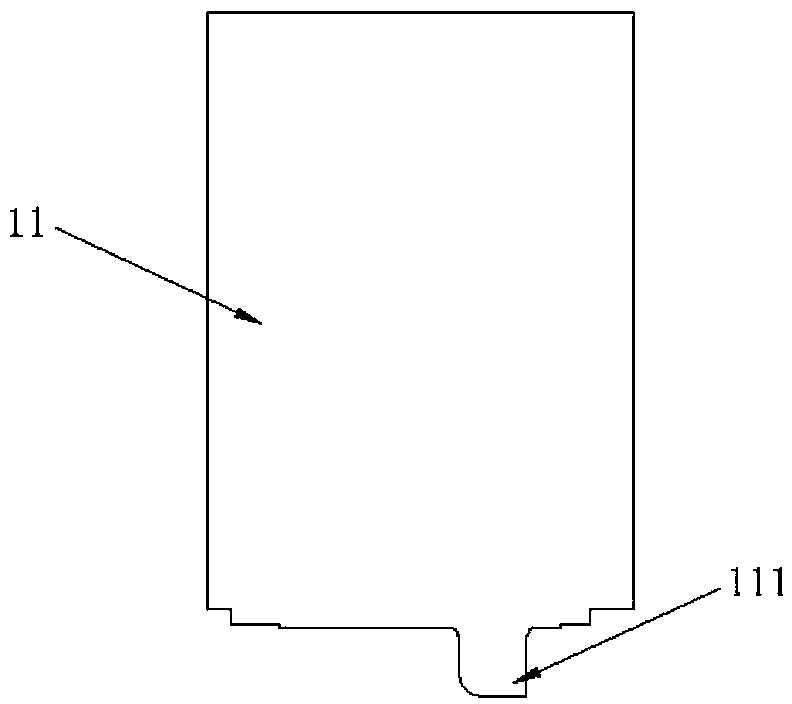

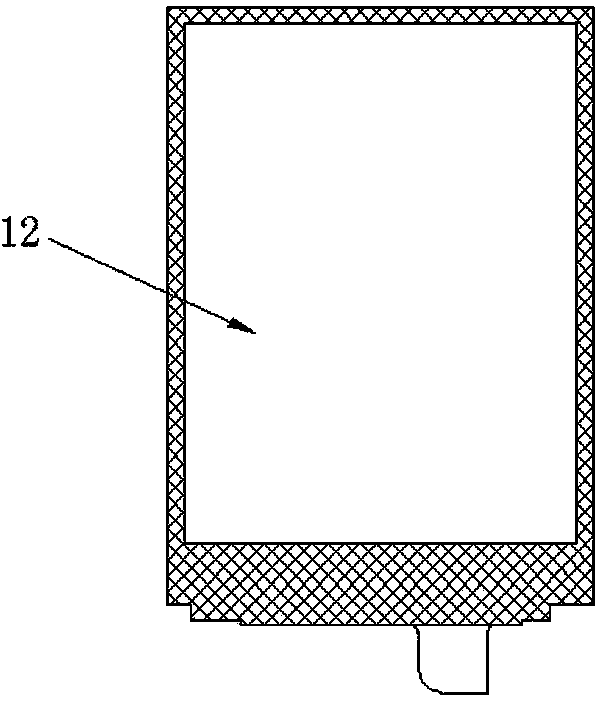

[0021] Please refer to Figure 5-8 As shown, a die-cutting preparation method for attaching reflective strips with light-shielding glue, including the steps of hollowing out the second release film, punching the reflective strips, punching the inner frame and handle of the light-shielding glue, and punching the outer frame of the light-shielding glue:

[0022] The step of hollowing out the second release film is to attach the first protective film to the second release film 2. The first protective film has an adhesive surface, and its adhesive surface is sequentially attached to the second release film. The material cannot be biased or Paste reversely; further, the rubber surface of the first protective film is bonded to the non-release surface of the second release film, so that after the release surface of the second release film is bonded to the subsequent light-shielding glue, the light-shielding glue can be effectively peeled off, If the shading adhesive is attached to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com