Multi-station pipe end machining equipment

A processing equipment and multi-station technology, applied in the direction of metal processing equipment, metal processing, metal processing machinery parts, etc., can solve the problem that it is impossible to realize multiple manifolds to process pipe ends at the same time, and the requirements for automatic processing of pipe ends cannot be met. Problems such as low utilization rate can achieve the effect of improving equipment utilization rate, realizing assembly line operation and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

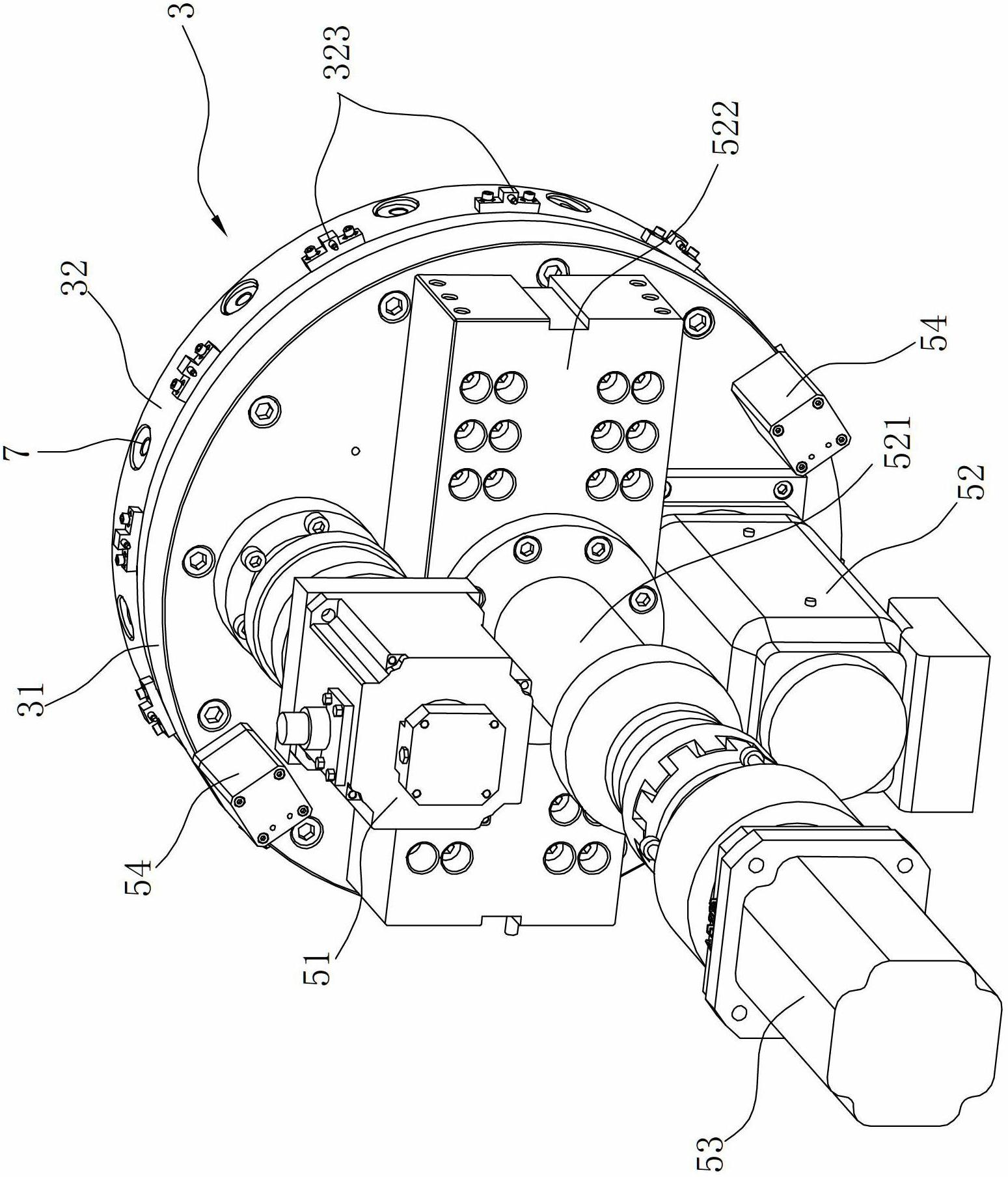

[0025] Such as Figure 1 to Figure 7 As shown, this embodiment is a multi-station pipe end processing equipment. The equipment adopts a turret tool 6, which can realize pipe end processing of special-shaped pipe fittings (such as automobile manifolds). The whole machine has a compact structure and high processing efficiency. high.

[0026]The multi-station pipe end processing equipment of this embodiment includes an organic base 1, a tool rest 3 installed on the base 1, and a pipe clamping device arranged directly in front of the tool rest 3, wherein the base 1 is semi-closed The U-shaped frame structure, the pipe clamping device is located at the U-shaped opening position of the machine base 1, the pipe clamping device includes a workbench 2 and two working positions arranged on the workbench 2 (it is also possible to increase the work numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com