Preparation method for graphene oxide/polyvinylidene fluoride composite ultrafiltration membrane

A polyvinylidene fluoride and graphene technology, applied in chemical instruments and methods, ultrafiltration, membrane technology, etc., can solve the problems of poor hydrophilicity and poor anti-fouling properties, and achieve strong anti-fouling properties, low production costs, and affinity good water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

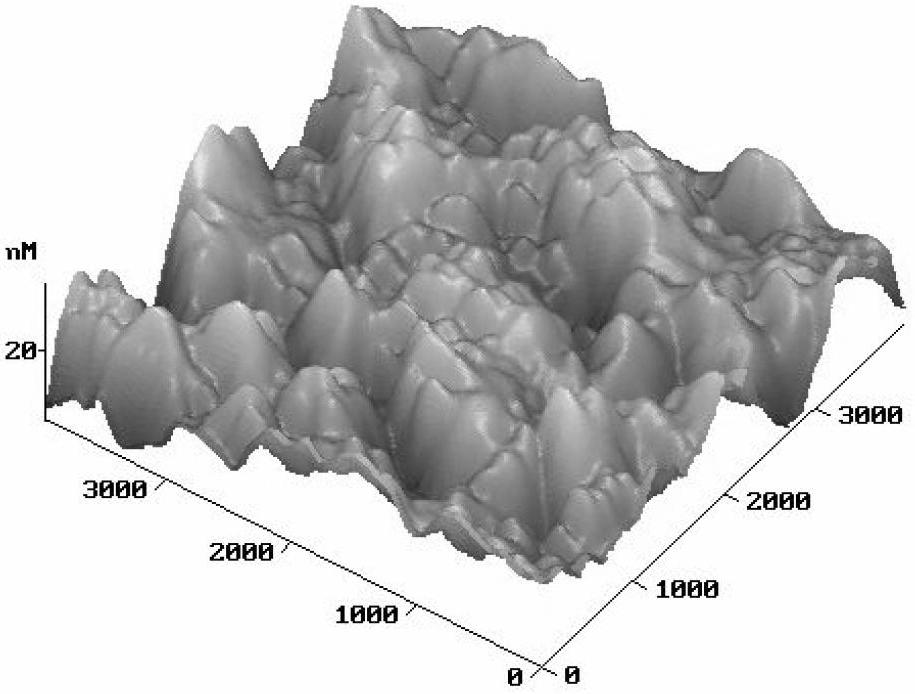

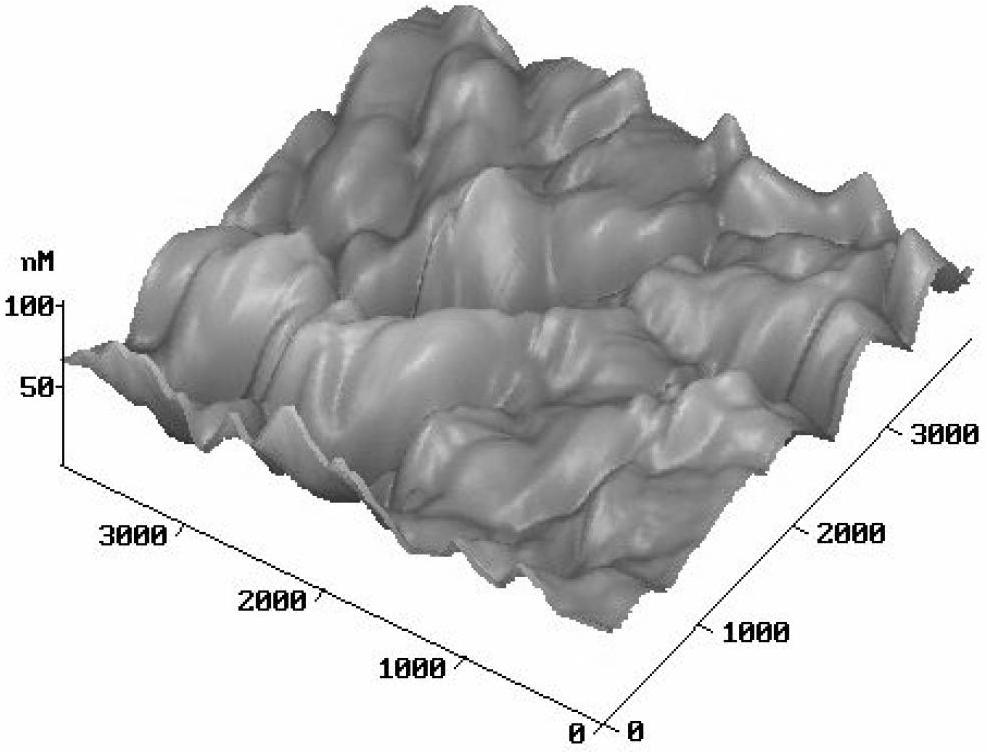

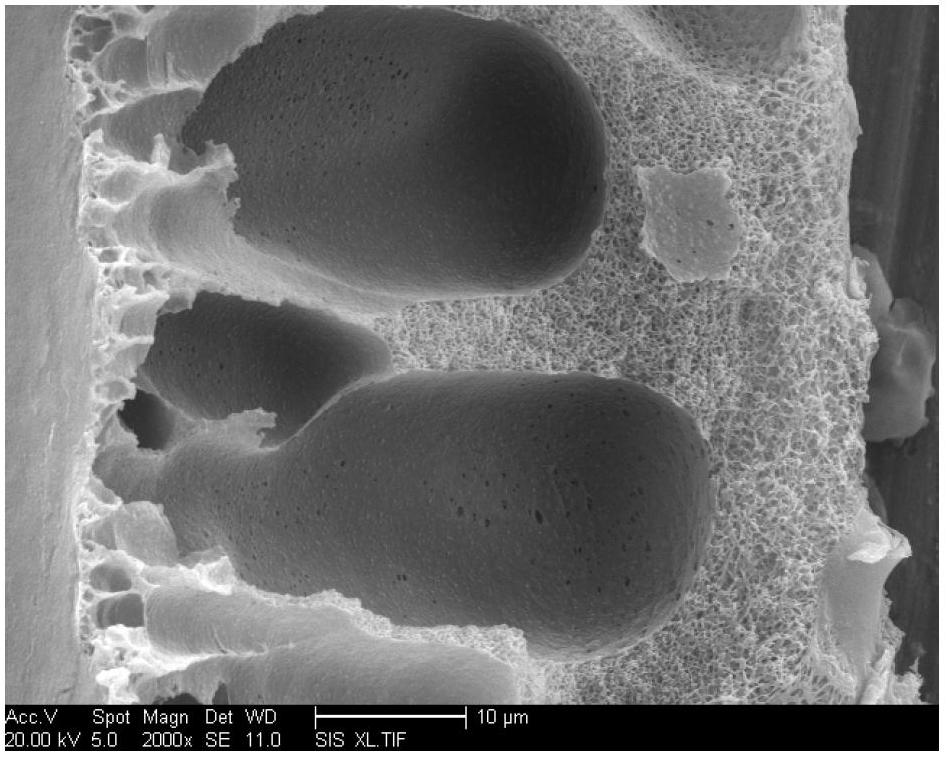

[0018] Specific embodiment one: the preparation method of a kind of graphene oxide / polyvinylidene fluoride composite ultrafiltration membrane in this embodiment is carried out according to the following steps:

[0019] 1. At a temperature of 20~24°C, weigh N-methylpyrrolidone and graphene oxide into a three-necked bottle according to the ratio of mass ratio (81~85):1, and ultrasonicate under the condition of 240~260W 1.8~2.2h, then according to the mass ratio of graphene oxide, polyvinylpyrrolidone and polyvinylidene fluoride in the ratio of 1:1:(14~18), respectively weigh polyvinylpyrrolidone and polyvinylidene fluoride into the three-necked bottle , put the three-neck flask in a water bath at a temperature of 42-48°C, keep the rotation speed at 400-600rpm and continue stirring for 11-13 hours to obtain the casting solution;

[0020] 2. Put the casting solution prepared in step 1 on a clean glass plate. The thickness of the coating film set by the film applicator is 140~160μm...

specific Embodiment approach 2

[0027] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the graphene oxide described in step one is prepared according to the following steps:

[0028] 1. Weigh flake graphite, sodium nitrate and potassium permanganate respectively according to the ratio of mass ratio (1.2~1.5):1:(8~10), then add flake graphite and sodium nitrate to the Put it into a three-necked flask and put it into an ice-water bath to cool to 0~5°C, and pour it into the three-necked flask according to the ratio of the sum of the mass of flake graphite and sodium nitrate to the volume of concentrated sulfuric acid: 1g: (40~50) mL Add concentrated sulfuric acid with a mass fraction of 98%, and add 2 / 3 parts of the above-mentioned potassium permanganate under the condition that the stirring speed is 2500~3000rpm and the temperature is 6~8°C. The whole process of adding potassium permanganate continues 0.8~1.2h, then put it in an ice-water bath, keep the rotation ...

specific Embodiment approach 3

[0031] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 1, at a temperature of 21-23°C, N- Add methylpyrrolidone and graphene oxide into the three-necked flask. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com