Method for compacting and treating micro-radioactive waste

A radioactive waste and treatment method technology, applied in the field of mechanical packaging of waste, can solve the problems of increasing the structural complexity of the barrel-carrying trolley, increasing maintenance costs, and increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific examples.

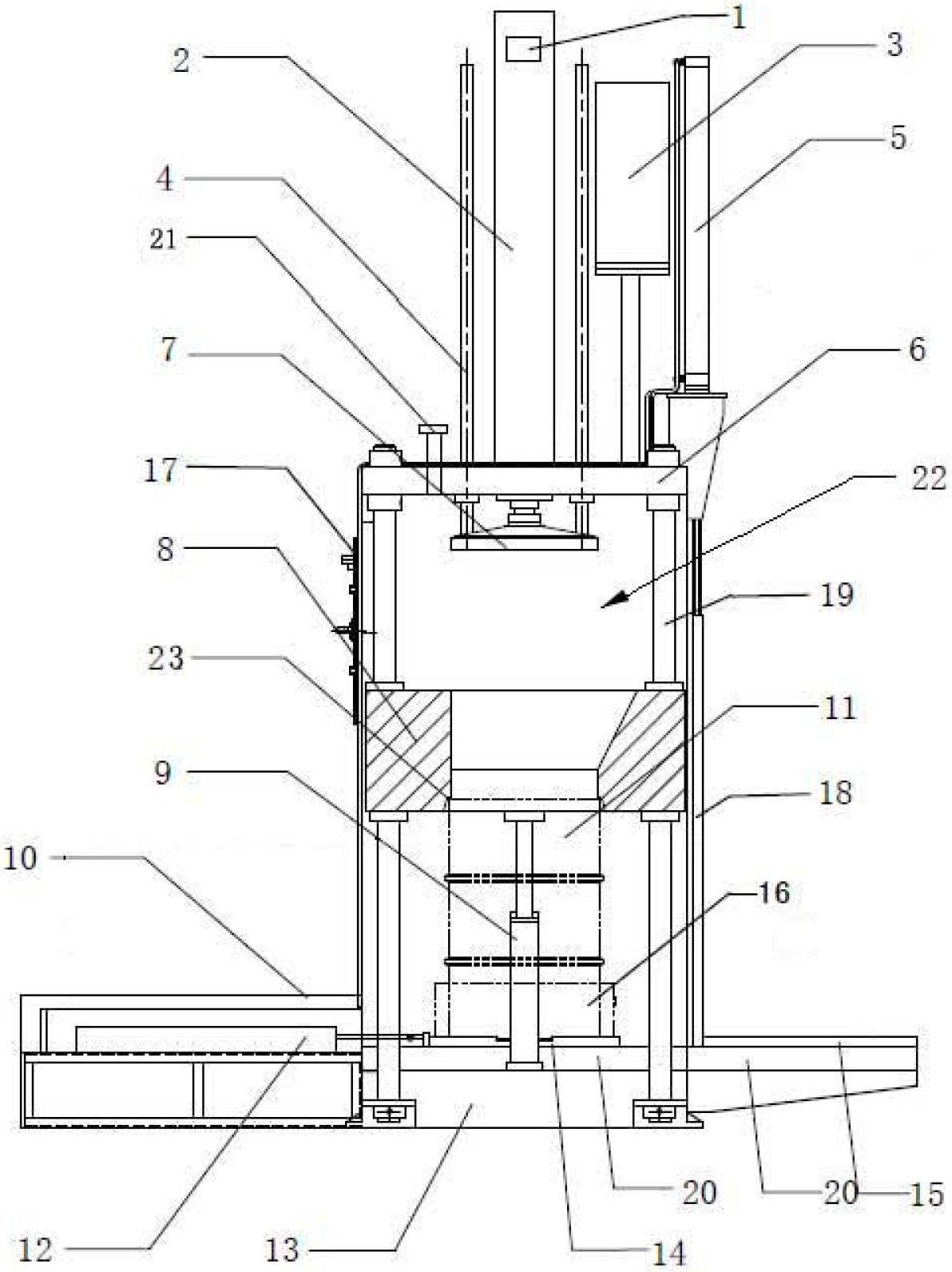

[0022] A compaction treatment method for micro-radioactive waste. The compaction treatment is completed on a four-column compactor, and the compaction action is carried out in a compaction chamber 22 in a closed state. The door 17 and the exhaust port 21, the exhaust gas in the compaction process is discharged from the exhaust port 21 to the central processing system for processing, which includes the following steps;

[0023] A. The lifting door 18 of the in-out bucket is in an open state, and the waste bucket 11 is fixedly installed on the in-out bucket slider 14 outside the compaction chamber 22;

[0024] B. Pull the barrel slider 14 to make the waste barrel 11 enter the compaction chamber 22 and put it in place, and the pulling action is realized by the push-pull cylinder 12;

[0025] C. Close the lifting door 18 of the in-out bucket, and the transition bucket 8 installe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com