Reactor Control Rod Drive Mechanism Pressure Shell Breaking Treatment Device

A driving mechanism and processing device technology, applied in the direction of reactor, reactor fuel element, greenhouse gas reduction, etc., can solve the problem of the unreported technology of the pressure shell breaking root of the driving mechanism of the reactor control rod, so as to improve the maintenance efficiency and ensure the safe operation. , the effect of reducing expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

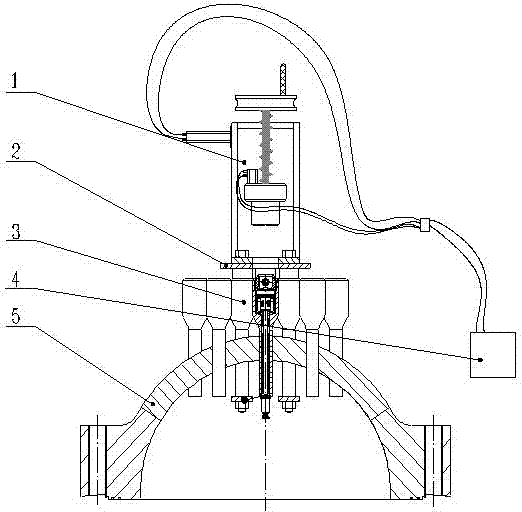

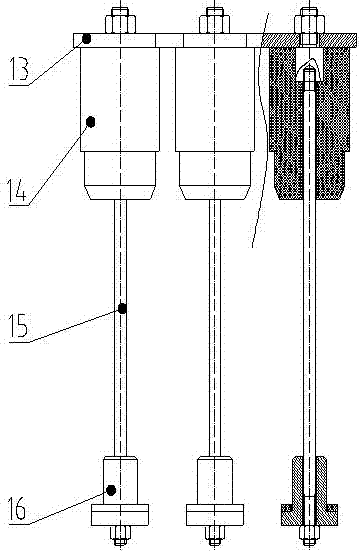

[0021] Such as figure 1 As shown, the reactor control rod driving mechanism pressure case root removal treatment device is composed of three major parts: a special boring head 1, a boring head support 2 and a hydraulic station 4.

[0022] The special boring and drilling head 1 is installed on the boring and drilling head support 2; the drilling head support 2 is installed on the top cover assembly 5 through the pipe seat 3; the hydraulic station 4 is connected with the special boring and drilling head 1 through the pipeline and the oil circuit controller.

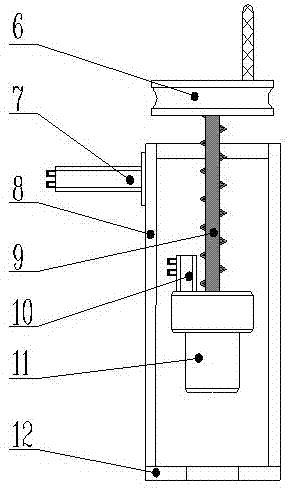

[0023] Such as figure 2 As shown, the special boring and drilling head 1 is composed of a manual feed wheel 6, a feed motor 7, a support frame 8, a feed screw 9, a spindle motor 10, a chucking head 11 and an installation base 12.

[0024] The manual feed wheel 6 is docked with the feed screw 9 and fixed on the feed motor 7; the feed motor 7 is docked with the feed screw 9 and fixed on the support frame 8; the support fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com