Heating cooling test method and heating cooling test device

A cooling test and cooling device technology, applied in measuring devices, material thermal analysis, instruments, etc., can solve problems such as temperature changes, difficulty in shortening product development time, and greater influence of heating of electronic components, and achieve the effect of simple temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

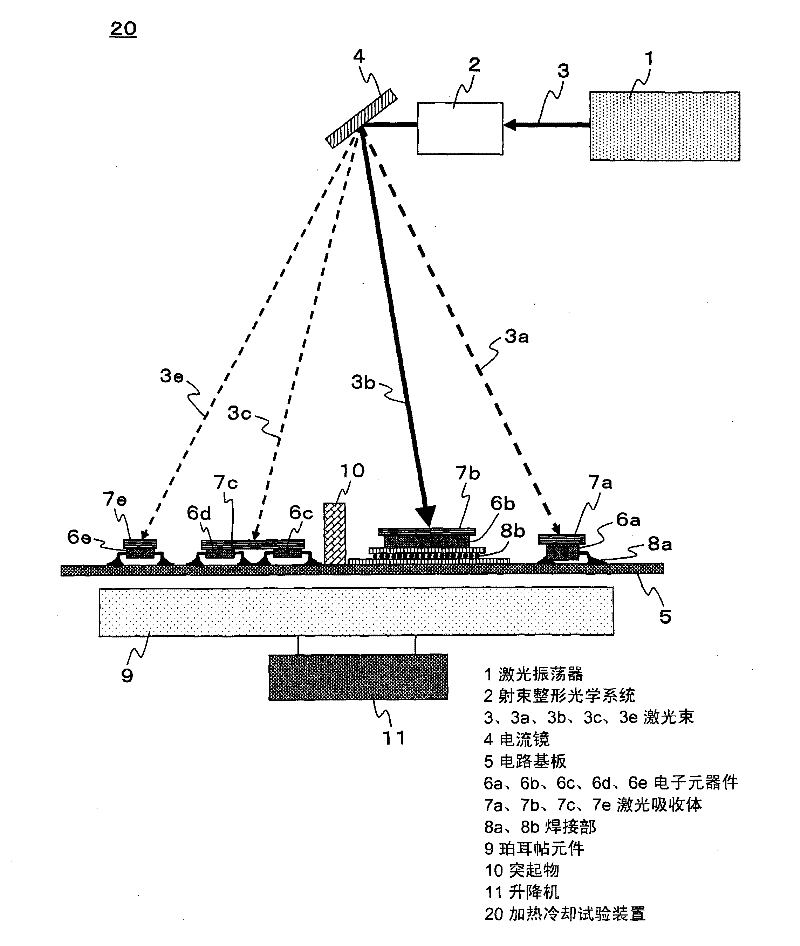

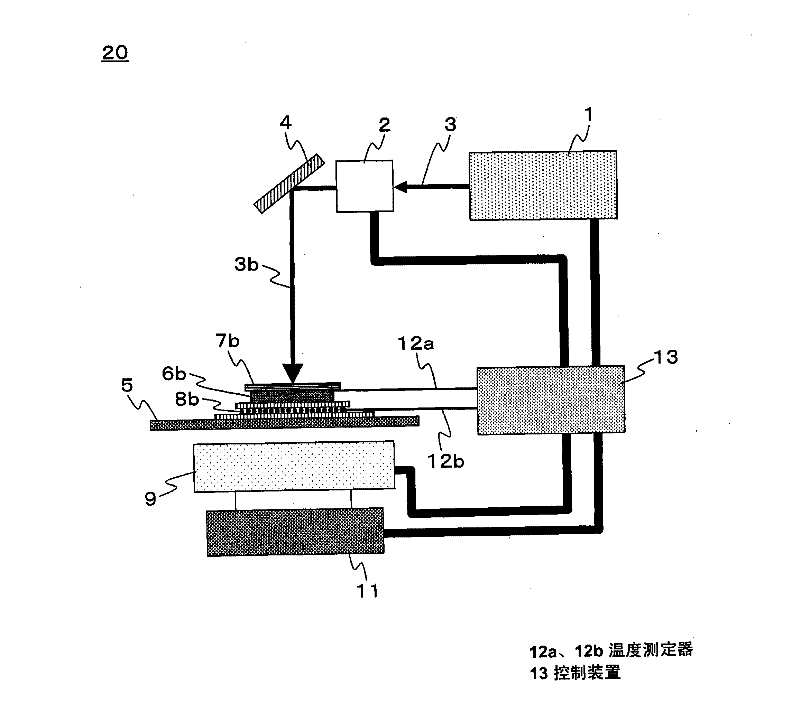

[0104] figure 1 A configuration diagram showing a heating-cooling test device used when implementing the heating-cooling test method in Embodiment 1 of the present invention.

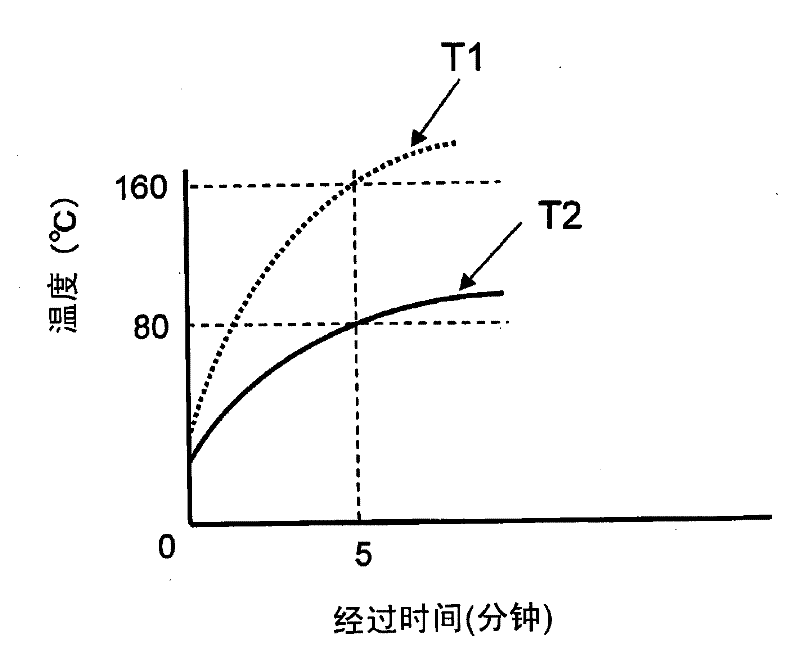

[0105] The outline of the heating and cooling test apparatus 20 according to Embodiment 1 is that laser absorbers 7a, 7b, and 7c are mounted on the upper surfaces of the electronic components 6a to 6e on the circuit board 5 on which a plurality of electronic components 6a to 6e are mounted. , 7e, the laser beam 3 emitted from the laser oscillator 1 is reshaped by the beam shaping optical system 2, and irradiated onto the laser absorbers 7a, 7b, 7c, 7e to make it heated, passing through the laser beam from the laser absorber 7a, The heat conduction of 7b, 7c, and 7e makes the electronic components 6a~6e heat up, after that, the irradiation of the laser beam 3 is stopped, and the solid cooling body (Peltier element 9) is heated from the opposite side where the electronic components 6a~6e are mounted. Th...

Embodiment approach 2

[0156] Figure 9 It is a cross-sectional configuration diagram of a main part of a heating-cooling test device according to Embodiment 2 of the present invention. and figure 2 The same reference numerals are used for the same structural parts.

[0157] Figure 9 It shows the laser irradiation position of the laser beam 3b with respect to the laser absorber 7b on the electronic component 6b.

[0158] In Embodiment 1, such as figure 2 As shown, the laser beam 3b is irradiated so that the optical axis is located substantially in the center of the laser absorber 7b on the electronic component 6b.

[0159] However, in the electronic component 6b constituted by a certain BGA semiconductor package, the IC chip as the heat source 14 may be arranged at a position deviated from the center on the layout inside the electronic component 6b. For the laser absorber 7b in such an electronic component 6b, if the laser beam 3b is irradiated so that the optical axis is located directly ab...

Embodiment approach 3

[0162] Figure 10 It is a block diagram of the heating-cooling test apparatus 21 in Embodiment 3 of this invention at the time of heating. and figure 2 The same reference numerals are used for the same structural parts.

[0163] like Figure 10 As shown, the control device 13 of the third embodiment controls the galvano mirror 4 so that the laser beam 3b scans the entire surface of the laser absorber 7b on the electronic component 6b.

[0164] In the structures of Embodiments 1 and 2, the laser beam 3b is fixed to irradiate the predetermined position of the laser absorber 7b on the electronic component 6b, so the area of the electronic component 6b is relatively smaller than the laser beam diameter of the irradiated laser beam 3b. If it is too large, it may not be possible to completely and uniformly heat the entire surface of the laser absorber 7b.

[0165] For example, when the electronic component 6b is 30mm square and the laser absorber 7b is 35mm square, when the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com