Thermostat valve

A temperature-controlled valve and valve body technology, applied in balance valves, valve devices, valve details, etc., can solve the problems of piston shaft support ring 11b damage, large coolant flow resistance, and difficulty in ensuring quality uniformity, etc., to achieve production and assembly Ease, low part count, equal quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

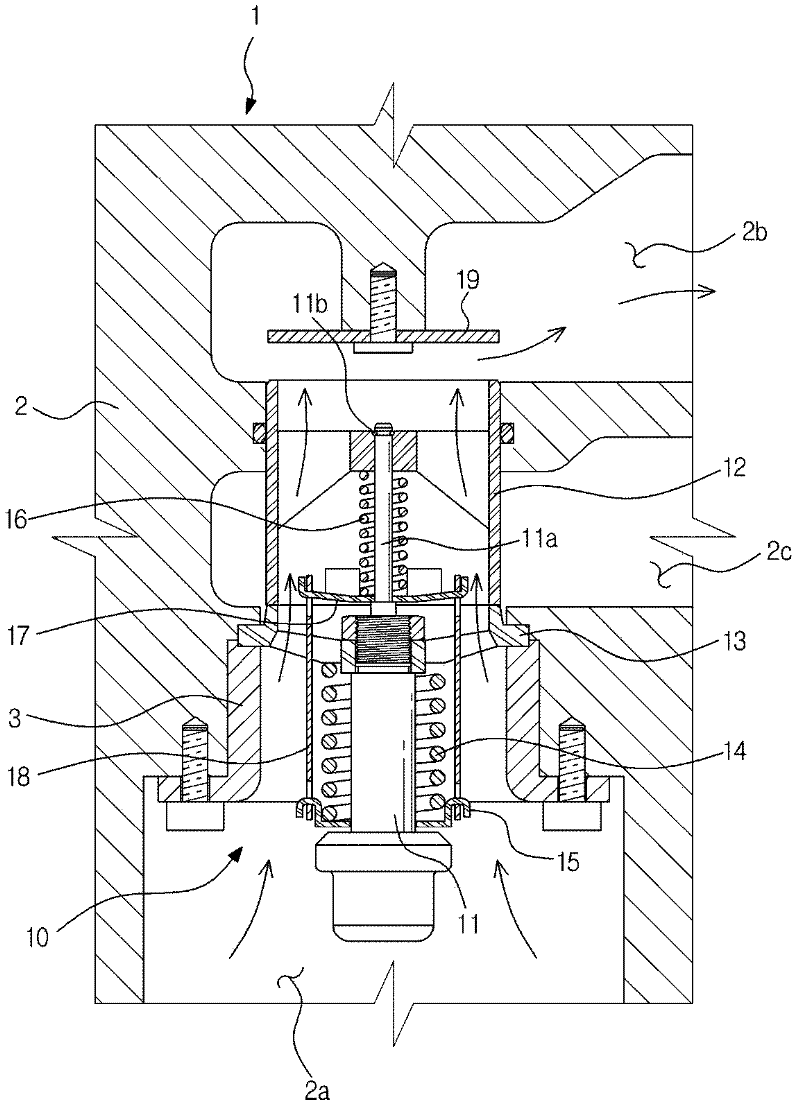

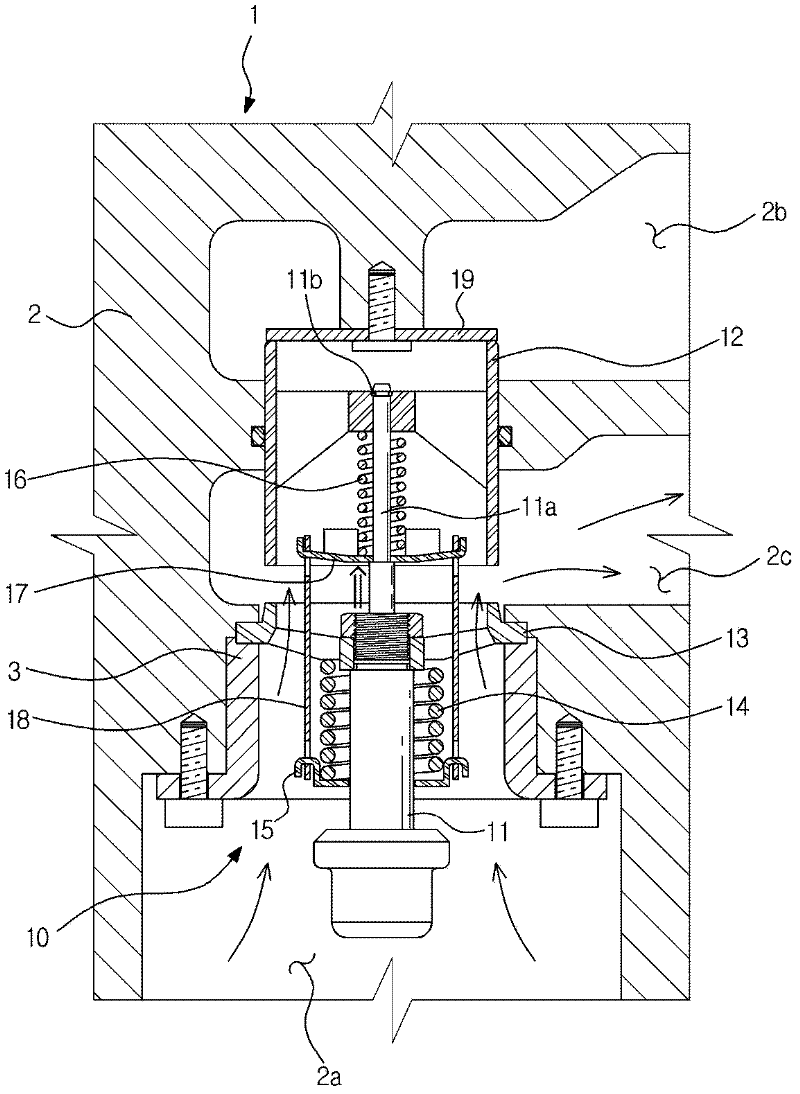

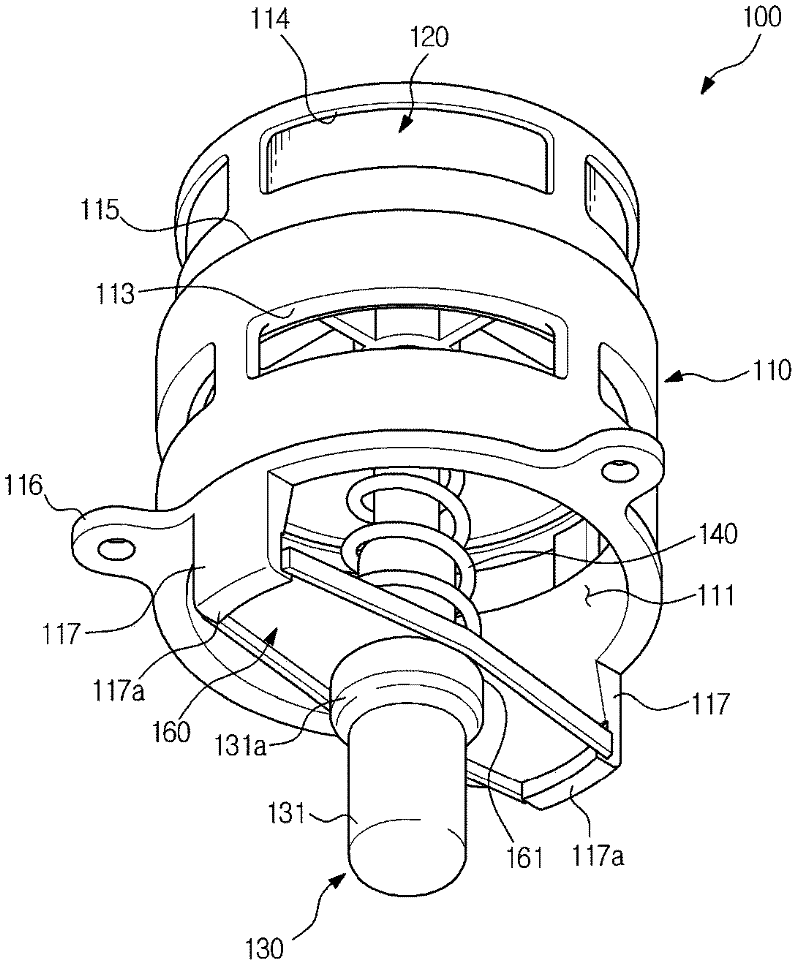

[0038] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

[0039] Such as Figure 4 As shown, the temperature control valve 100 provided by the present invention is arranged in the coolant flow path of a ship or a large industrial engine. The temperature control valve 100 plays the role of changing the flow path according to the temperature of the coolant flowing through the engine, so as to send the coolant to the flow path 31 connected to the water pump or the flow path 32 connected to the radiator. Here, although the case where the temperature control valve 100 is used in the coolant flow path of the engine is described as a preferable example, the application of the temperature control valve 100 of the present invention is not limited thereto, and it can also be applied to the temperature control valve 100 according to the temperature change of the fluid. Various industrial equipment or devices that need ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com