Transmission shaft braking wet multi-disc brake for driving axle

A transmission shaft and brake technology, applied in the direction of brake types, brake parts, mechanical equipment, etc., can solve the problems of brake maintenance, inconvenient maintenance and adjustment, poor heat dissipation conditions of tires, and decreased braking efficiency, etc., to achieve good heat dissipation effect , Restoring braking performance and good cooling conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

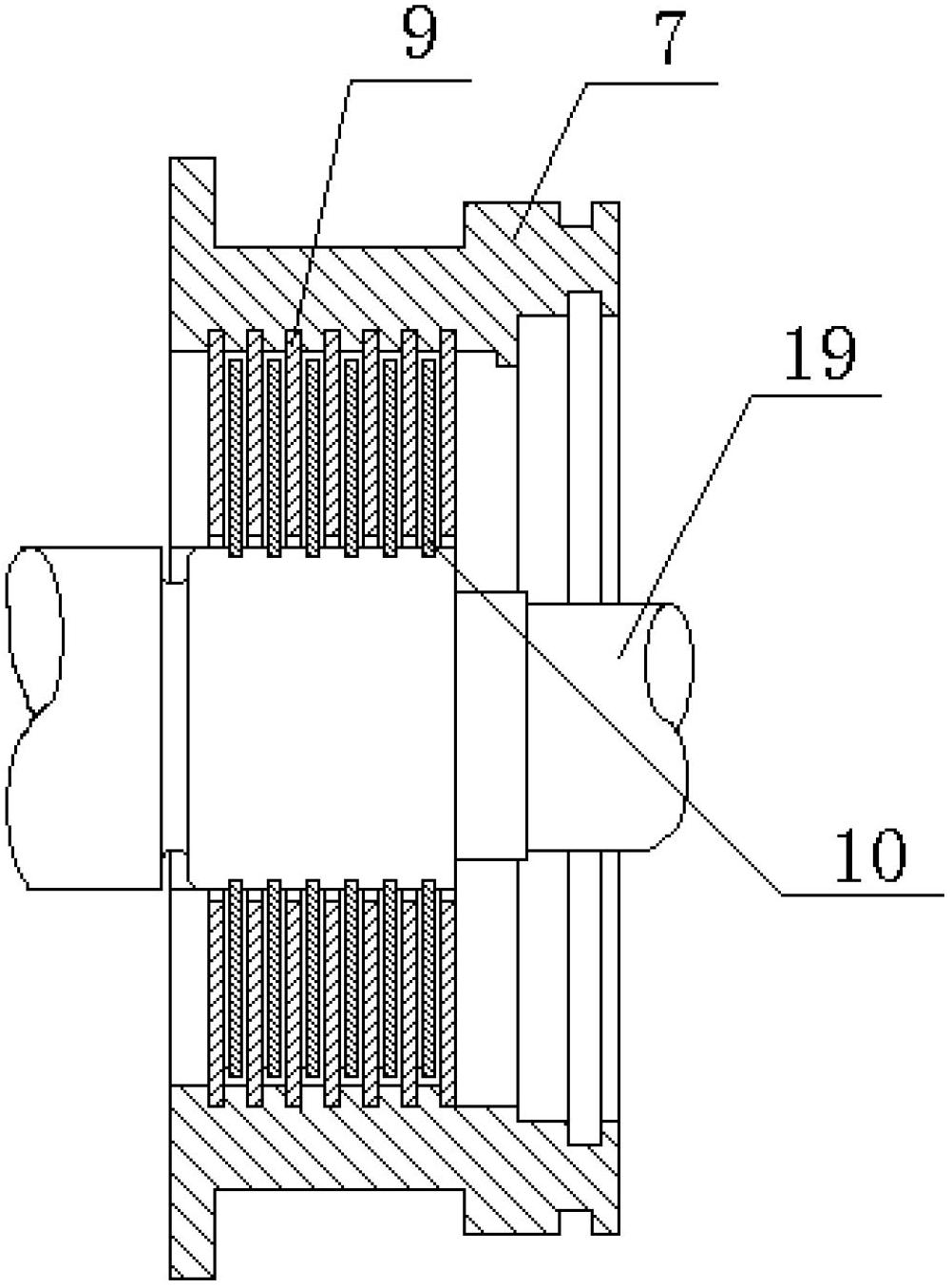

[0016] Such as figure 1 As shown, a transmission shaft braking type wet multi-disc brake for drive axles includes an inner casing 1, a middle casing 2, an outer casing 11 and a support shaft 19, and the inner casing 1 is connected to the middle casing 2 by bolts. At one end, the outer shell 11 is connected to the other end of the middle shell 2 by bolts; a blocking cover 20 is installed on the outer middle of the inner shell 1; an end cover 13 is installed on the outer middle of the outer shell 11; A number of spring blind holes are evenly distributed on the circumference coaxial with the support shaft. A threaded blind hole is opened in the center of the bottom surface of the spring blind hole. A spring 3 whose length is greater than the depth of the spring blind hole is placed in the spring blind hole, and a guide ring 4 is pressed on the spring 3 And the spring 3 is fixed by the screw 5; the middle shell 2 is cylindrical, and an oil inlet hole 8 is arranged on the middle pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com