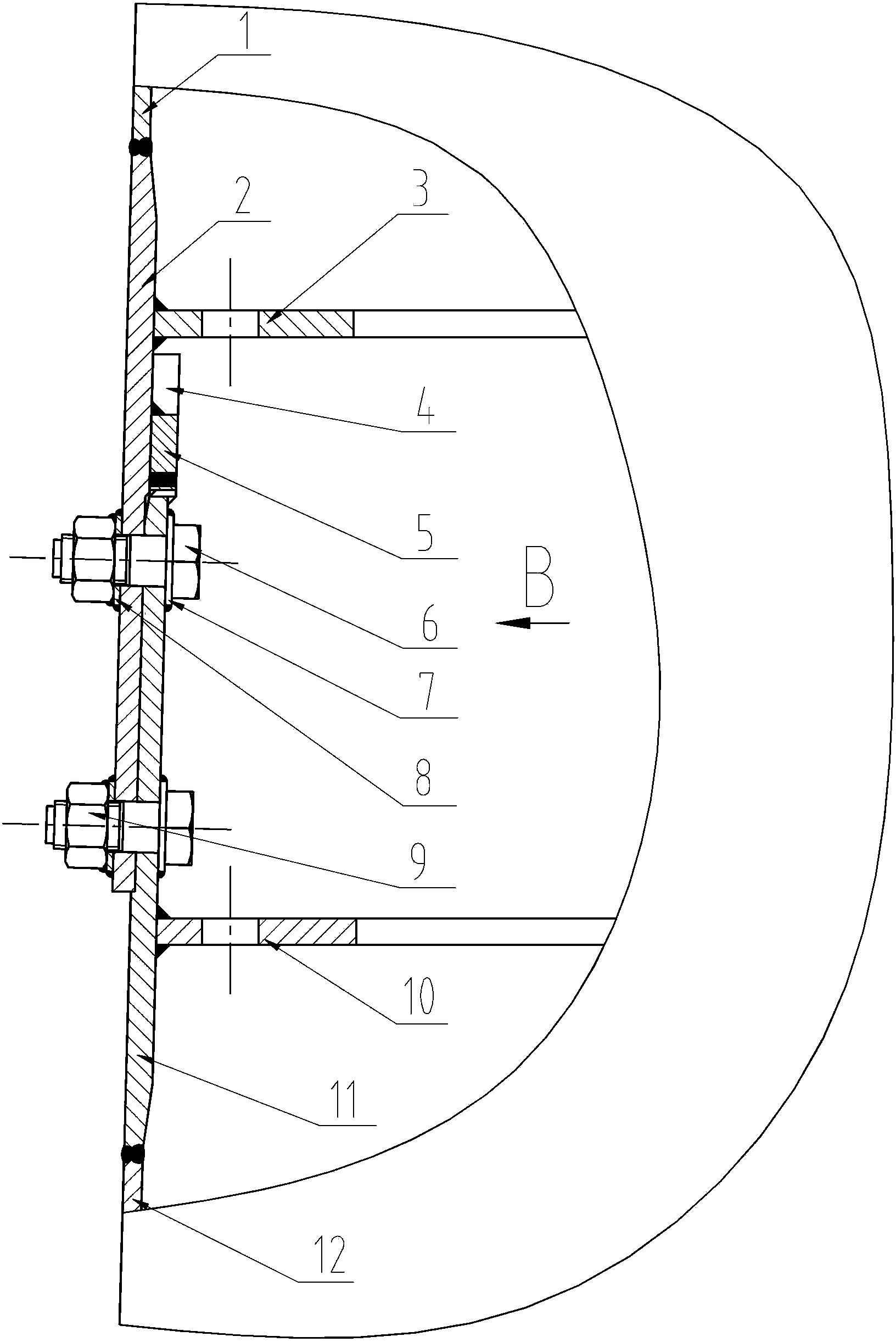

Flange-free connection mode and implementation method for barrel-type tower frame of large size wind turbine

A wind turbine, flangeless technology, used in wind turbine components, wind turbine assembly, wind power generation, etc., can solve the problem of high cost, achieve the effect of reliable strength, simple connection method, and save the procurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

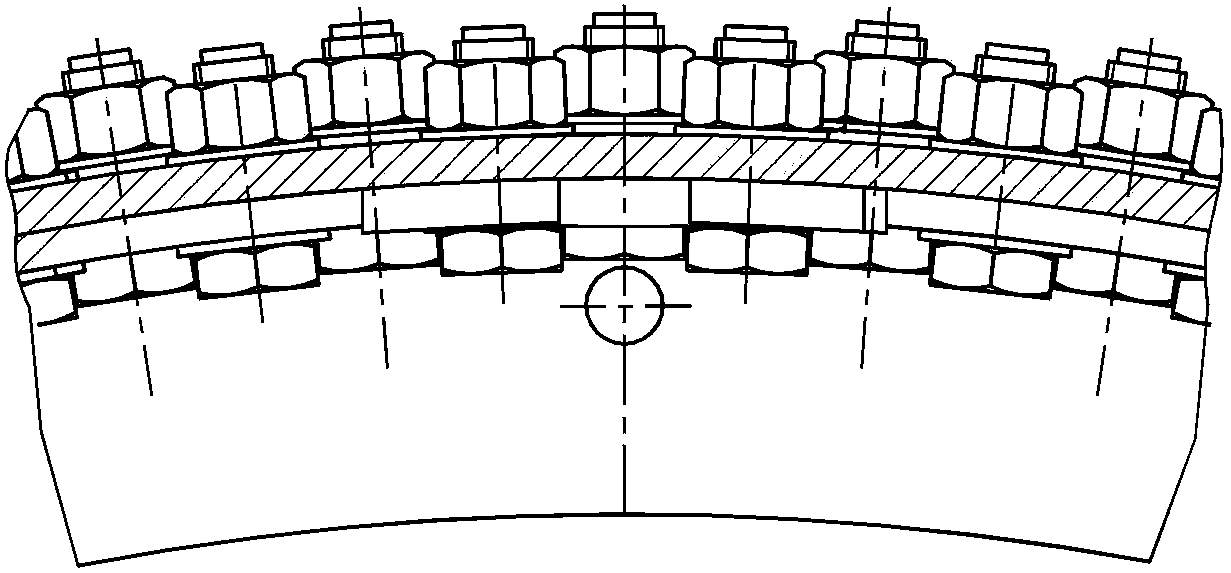

[0046] The implementation method of the flangeless connection mode of a large-scale wind turbine tubular tower of the present invention comprises the following steps:

[0047] (1) Factory manufacturing stage:

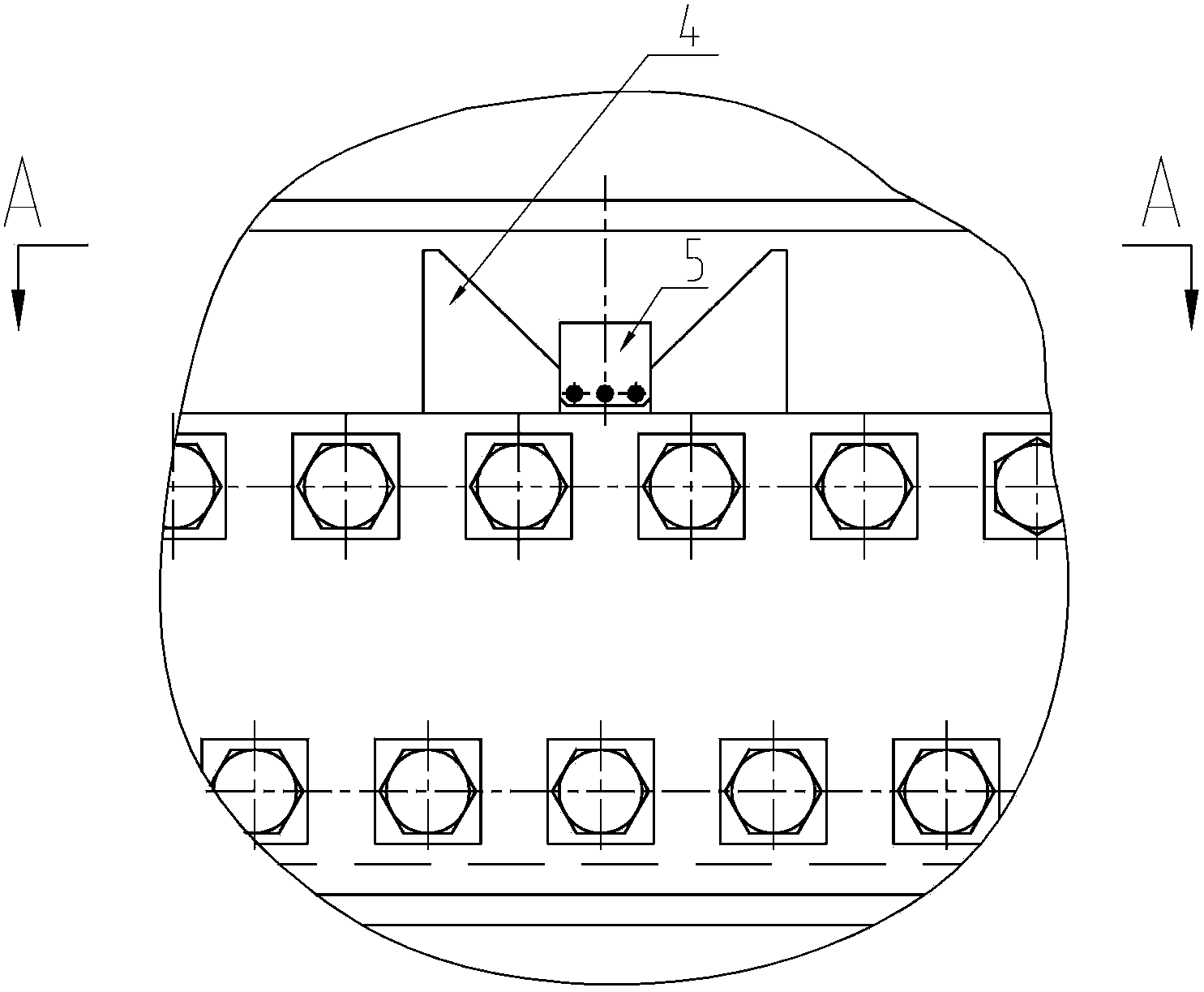

[0048]①Manufacture of the blank of the upper connecting section: according to the drawing, carry out blanking, tailor welding, coiling, re-tailoring and other processes, complete the manufacturing of the blank of the upper connecting section, including the ring-shaped rib plate of the upper section, and complete the shaping process of the blank;

[0049] ②Turning: complete the turning of the upper connection section according to the drawings, including the inner fit cone, the lower end surface, the upper transition cone and the upper welding groove;

[0050] ③ Drilling: complete the drilling process of the upper ring-shaped stiffener plate;

[0051] ④Complete the manufacturing and processing of the lower connection section according to the same process as above;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com