Combustion chamber of high-speed diesel engine

A combustion chamber and diesel engine technology, which is applied in combustion engines, mechanical equipment, machines/engines, etc., can solve problems affecting the rationality and distribution of airflow movement organization, low air utilization rate, and fuel oil beam hitting the wall, etc., so as to promote Effect of atomization and space mixing and distribution, reduction of local combustion high temperature zone, and reduction of initial combustion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

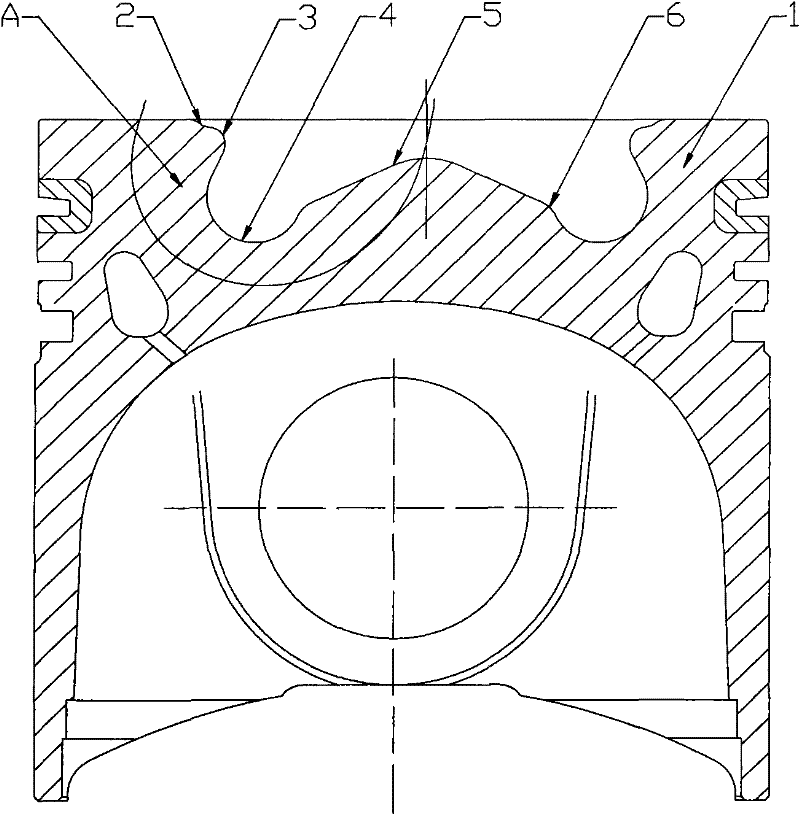

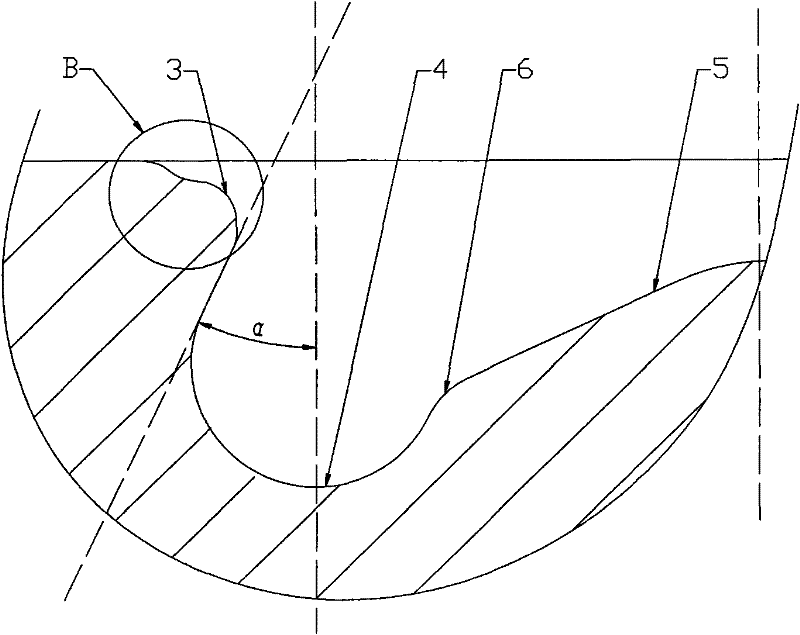

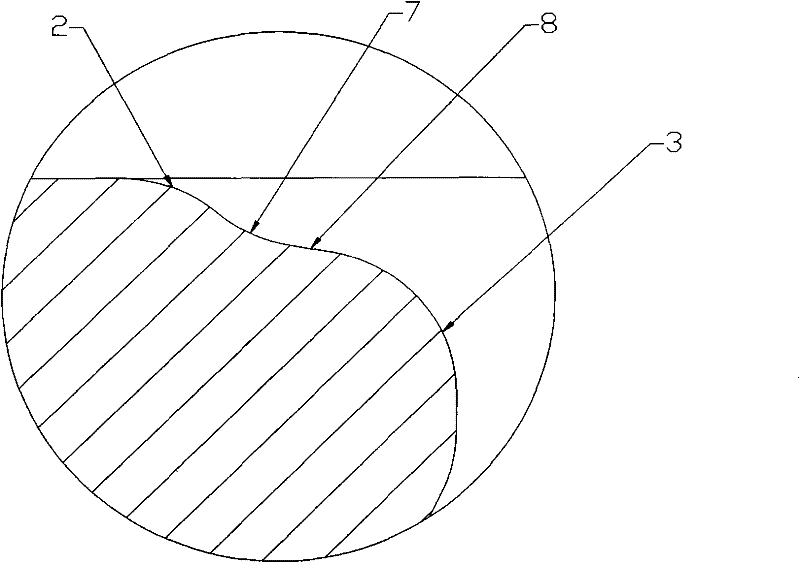

[0023] Figure 1 to Figure 4 Both are the content of Embodiment 1, figure 1 It is a schematic cross-sectional view of the combustion chamber of this embodiment. As shown in the figure, the cross-section of the combustion chamber is generally ω-shaped. 3. Bottom groove 4 and boss 5. The inner constriction 2 is an annular arc-shaped protrusion whose inner diameter decreases from the top of the piston rod 1. The mouth 3 is an annular arc-shaped protrusion transitionally connected to the bottom edge of the inner constriction 2, and its section is also a circular arc with the opening facing away from the central axis of the combustion chamber. The bottom groove 4 is an arc-shaped groove arranged on the bottom edge of the combustion chamber , the section of which is an opening facing the central axis of the combustion chamber and an arc towards the upper side. The boss 5 is a spherical crown structure arranged at the center of the bottom of the combustion chamber. The deflector 6,...

Embodiment 2

[0031] Compared with the first embodiment, the shape and function of this embodiment are the same as those of the first embodiment except that the specific dimensions are changed, so the structural connection relationship and working process will not be repeated here.

[0032] In this embodiment, the maximum inner diameter of the inner constriction 2 is 58.2 mm, the radius of the arc of the inner constriction 2 is 2 mm, the minimum inner diameter of the throat 3 is 49.1 mm, and the center of the arc of the throat 3 is aligned with the piston rod. The distance from the top of 1 is 2.5mm, the radius of the arc of the bottom groove 4 is 5.6mm, the distance from the center of the arc of the bottom groove 4 to the central axis of the combustion chamber is 20mm, and the center of the arc of the bottom groove 4 to the top of the piston rod 1 The distance between the tangent of the upper edge of the arc and the central axis of the combustion chamber is 20°, the radius of the boss 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com