Housing and manufacturing method thereof

A production method and shell technology, applied in the field of shell and its production, can solve the problems of limited color and few colors of the film layer, and achieve the effect of improving the competitiveness of the appearance and enriching the colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

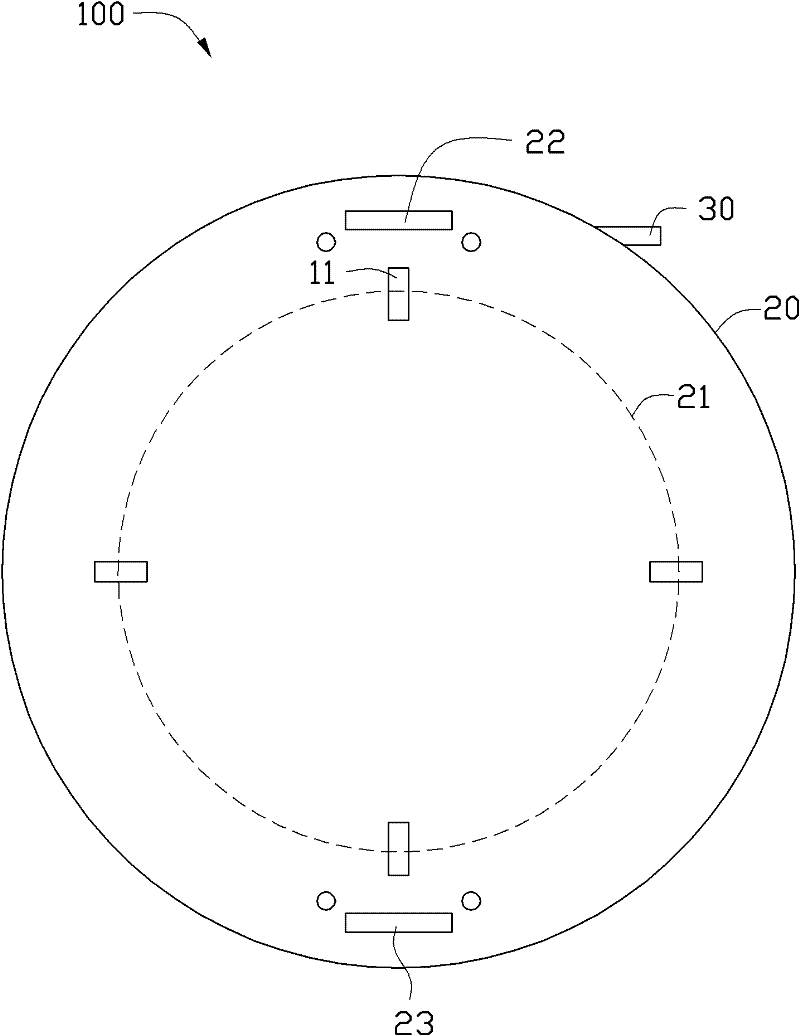

[0052] Cleaning: Put the substrate 11 into absolute ethanol for ultrasonic cleaning and dry it for later use.

[0053] Sputtering color layer 13: form a titanium oxynitride layer 131 on the substrate 11, set the temperature of the coating chamber 20 to 100°C, set the power of the titanium target 22 to 7kw, the flow rate of argon gas to 150 sccm, and apply the bias voltage to the substrate 11 as -250V, set the duty cycle of the bias voltage to 50%; use oxygen and nitrogen as the reaction gases, the initial flow of oxygen is 30sccm, the initial flow of nitrogen is 15sccm, and the flow of oxygen and nitrogen increases in a gradient during the sputtering process .

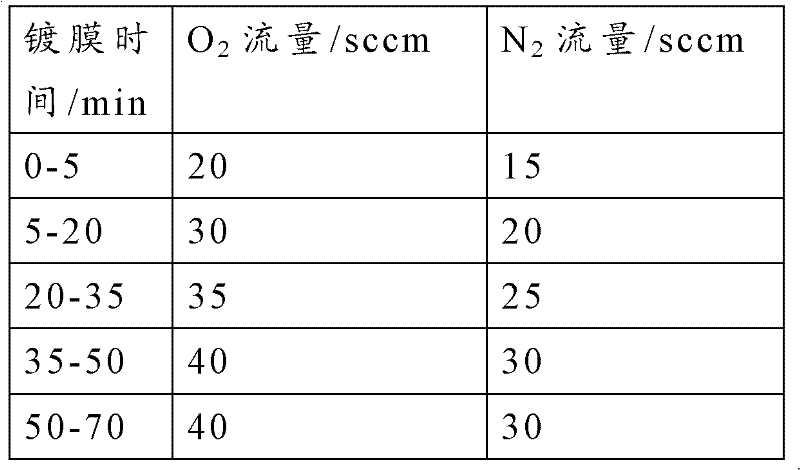

[0054] The specific gradient increase method of oxygen and nitrogen flow is shown in Table 1.

[0055] The mass percentages of Ti, O and N in the titanium oxynitride layer 131 are 54%, 39% and 7% respectively, and the mass percentages of Al and O in the aluminum oxide layer 133 are respectively 65%, 35%.

[0056]Aft...

Embodiment 2

[0059] Cleaning: Put the substrate 11 into absolute ethanol for ultrasonic cleaning and dry it for later use.

[0060] Sputtering color layer 13: form a titanium oxynitride layer 131 on the substrate 11, set the temperature of the coating chamber 20 to 150°C, set the power of the titanium target 22 to 8kw, the flow rate of argon gas to 200 sccm, and apply the bias voltage to the substrate 11 as -200V, set the duty cycle of the bias voltage to 50%; use oxygen and nitrogen as the reaction gas, the initial flow of oxygen is 40sccm, the initial flow of nitrogen is 20sccm, and the flow of oxygen and nitrogen increases in a gradient during the sputtering process .

[0061] The specific gradient increase method of oxygen and nitrogen flow is shown in Table 1.

[0062] The mass percentages of Ti, O and N in the titanium oxynitride layer 131 are 52%, 40% and 8% respectively, and the mass percentages of Al and O in the aluminum oxide layer 133 are respectively 64%, 36%.

[0063] Afte...

Embodiment 3

[0066] Cleaning: Put the substrate 11 into absolute ethanol for ultrasonic cleaning and dry it for later use.

[0067] Sputtering color layer 13: form a titanium oxynitride layer 131 on the substrate 11, set the temperature of the coating chamber 20 to 200° C., set the power of the titanium target 22 to 9 kw, and the flow rate of argon gas to 300 sccm. The bias voltage applied to the substrate 11 is -200V, set the duty cycle of the bias voltage to 50%; use oxygen and nitrogen as the reaction gas, the initial flow of oxygen is 40sccm, the initial flow of nitrogen is 20sccm, and the flow of oxygen and nitrogen increases in a gradient during the sputtering process .

[0068] The specific gradient increase method of oxygen and nitrogen flow is shown in Table 1.

[0069] The mass percentages of Ti, O and N in the titanium oxynitride layer 131 are 51%, 40% and 9% respectively, and the mass percentages of Al and O in the aluminum oxide layer 133 are respectively 63%, 37%.

[0070]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com