Suspension type skimbar putting device

A technology of throwing device and slag blocking rod, applied in the direction of manufacturing converters, etc., can solve the problems of inconvenient maintenance, overhaul, low throwing success rate, occupying floor space, etc., and achieves compact structure, guaranteed deceleration and stop position, and reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

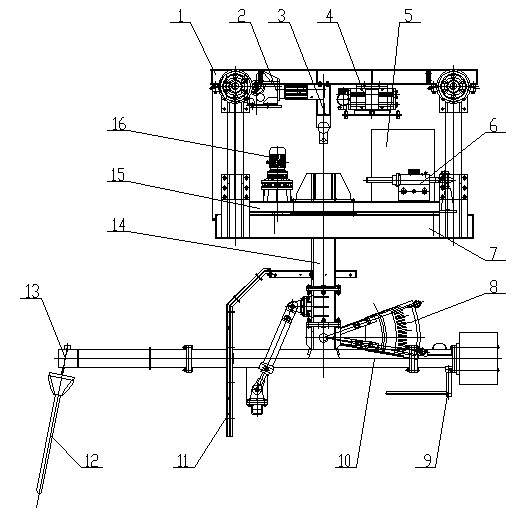

[0027] (Reference figure 1 1) A suspension-type slag bar throwing device, including a cantilever bar tilting device 10, a slag bar holding device 13, and an energy medium system 3. The slag bar holding device 13 is arranged in the cantilever rod of the cantilever bar tilting device 10 The energy medium system 3 is used to cool the front end of the cantilever rod of the cantilever rod tilting device 10 and the slag stop rod holding device 13, which also includes a walking platform 1, a suspension platform 7, a rotating platform 15 and a vehicle hydraulic Station 5, the energy medium system 3 and the vehicle-mounted hydraulic station 5 are set on the rotating platform 15, and the rotating platform 15 is set on the suspended platform 7, and can rotate relative to the suspended platform 7 under the driving of the rotating platform driving device 16 , The cantilever rod tilting device 10 is connected to the rotating platform 15 through the cantilever rod hanger 14, the suspension pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com