Composite ionic soil curing agent and manufacturing method thereof

A soil stabilizer and composite ion technology, which is applied in the field of fine chemicals, can solve the problems that it cannot adapt to various soils of different properties, has few practical applications, and has high soil quality requirements, and achieves excellent antifreeze performance, less dosage, and water stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0028] In laboratory state:

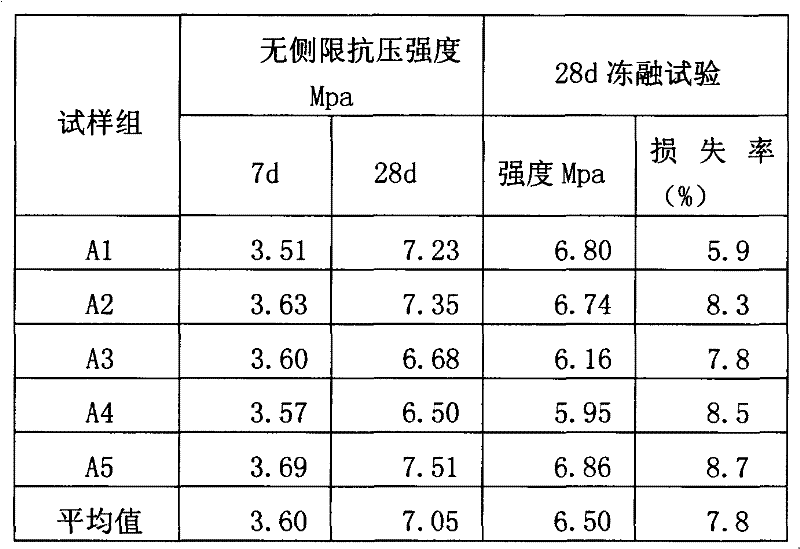

[0029] According to the "Soil Engineering Test Regulations", take the soil sample through a 5mm sieve, add 4% of 32.5 grade cement to the outside, and configure a composite ion soil curing agent according to the proportion of 0.02% of the volume of the test block, and mix it with an appropriate amount of water to dilute and mix it. into a 50mm × 50mm test piece. There are 45 in 5 groups, according to the "Technical Regulations CJJ / T80-98 for Cured Pavement Base and Subbase", "Soil Stabilizer 3073-1998" and "JTG E51-2009 Highway Engineering Inorganic Binder Stable Materials Test Procedures" and operate and For the test, 3 specimens were taken from each group, and the unconfined compressive strength reached 3.60Mpa on average for 7 days (6 days of standard cultivation + 1 day of water immersion), which met the design requirements of expressway roads; (27 days of standard culture + 1 day of water immersion) the unconfined compressive strength reache...

Embodiment example 2

[0033]The factory road in an industrial zone in the central part of Guangxi was selected. The paved area is about 20,000 square meters. The construction time is from January to May 2010. The soil liquid limit in this area is 44%, the plastic limit is 24%, and the plasticity index is 20. It belongs to clayey soil. The mixture ratio of road base course is, soil curing agent: calcium carbide slag: plain soil = 0.02%: 3%: 97%; : 3%: 3%: 94%, wherein, the cement is 32.5 grade ordinary cement, the carbide slag is the industrial waste of PVC enterprises, and the main component is Ca(OH) containing saturated water 2 , plain soil is the soil that needs to be shipped out during the construction of the plant. After the construction is completed, the subgrade will be inspected by the inspection unit. The compaction degree of the pavement base and subbase has reached more than 95%, the deflection value is only in the range of 60-100 (0.01mm), and the rebound modulus is between 125.5-217MP...

Embodiment example 3

[0035] Select the municipal road in the new development zone of a city in Guangxi District, with an area of about 1,800 square meters. The soil in this area belongs to weak expansive soil, and the local government has clearly stipulated that the soil cannot be used as roadbed backfill soil without treatment. The mixture ratio of road base course is, soil curing agent: carbide slag: plain soil=0.02%: 6%: 94%; the mixture ratio of road base course is soil curing agent: cement: calcium carbide slag: plain soil=0.02% : 3% : 6% : 91%. After the project is completed, the testing unit will test the compactness and rebound deflection value. After testing, the compaction degree of the base layer is above 97%, representing a deflection value of 159.8 (0.01mm); the compaction degree of the base layer is above 98%, representing a deflection value of 47.8 (0.01mm), all reaching or even exceeding the design Require. The soil used in this project is the accumulated waste soil developed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| compactness | aaaaa | aaaaa |

| compactness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com