Antifreeze liquid film for pulverized coal transport and preparation method and application thereof

A technology of antifreeze and pulverized coal, applied in coatings, conjugated diene coatings, chloroprene homopolymer coatings, etc., can solve the problem of reducing the use effect and aging of antifreeze, less antifreeze, and waste of antifreeze And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

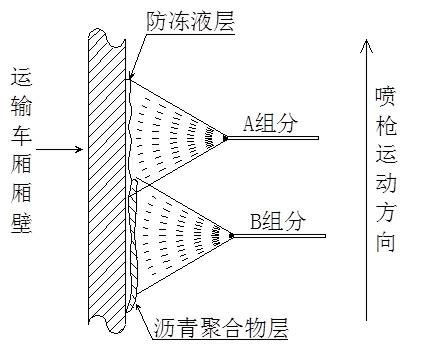

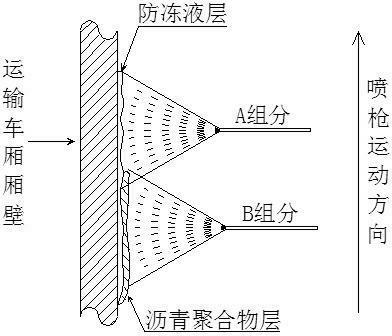

Method used

Image

Examples

specific Embodiment approach 1

[0030] Implement the preparation method of antifreeze liquid for transportation of the present invention, and its composition and content are all as follows by mass parts:

[0031] Component A: Take 70 parts of industrial water and place it in a mixer with stirring, then add 26 parts of industrial calcium chloride, 0.1 part of sodium benzoate, 0.2 part of disodium hydrogen phosphate, 0.5 part of sodium nitrite, and 0.2 part of triethanolamine , 3 parts of ethanol, stir and dissolve the above materials at room temperature and mix evenly to obtain component A of antifreeze.

[0032] Component B: Take 70 parts of emulsified petroleum asphalt with a mass content of 45-50% and place it in a mixer with stirring, then add 1 part of emulsified neoprene latex with a mass content of 49-51% and emulsified styrene-butadiene with a mass content of 49-51% 1 part of latex, 0.1 part of defoamer BYK-024, 27.9 parts of industrial water; Stir and mix the above materials evenly at room temperatur...

specific Embodiment approach 2

[0034] Implement the preparation method of antifreeze liquid for transportation of the present invention, and its composition and content are all as follows by mass parts:

[0035] Component A: Take 61 parts of industrial water and place it in a mixer with stirring, then add 30 parts of industrial calcium chloride, 0.3 parts of sodium benzoate, 0.7 parts of disodium hydrogen phosphate, 1.5 parts of sodium nitrite, and 0.5 parts of triethanolamine , 6 parts of ethanol, the above materials were stirred and dissolved at room temperature and mixed evenly to obtain component A of antifreeze.

[0036] Component B: Take 70 parts of anionic emulsified petroleum asphalt with a mass content of 45-50% and place it in a mixer with stirring, then add 5 parts of emulsified chloroprene latex with a mass content of 49-51%, and emulsified butyl asphalt with a mass content of 49-51% 5 parts of benzene latex, 0.3 parts of defoaming agent BYK-024, 19.7 parts of industrial water, stir and mix the ...

specific Embodiment approach 3

[0038] Implement the preparation method of antifreeze liquid for transportation of the present invention, and its composition and content are all as follows by mass parts:

[0039] Component A: Take 64.6 parts of industrial water and put it in a mixer with stirring, then add 28 parts of industrial calcium chloride, 0.2 parts of sodium benzoate, 0.6 parts of disodium hydrogen phosphate, 1.3 parts of sodium nitrite, and 0.3 parts of triethanolamine , 5 parts of ethanol, the above materials are stirred and dissolved at room temperature and mixed evenly to obtain component A of antifreeze.

[0040] Component B: Take 70 parts of anionic emulsified petroleum asphalt with a mass content of 45-50% and place it in a mixer with stirring, then add 4 parts of 49-51% emulsified chloroprene latex, with a mass content of 49-51% emulsified styrene-butadiene latex 4 parts, 0.2 parts of defoaming agent BYK-024, 21.8 parts of industrial water, stir and mix the above materials at room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com