Long-chain branched polylactic resin and preparation method and application thereof

A technology of polylactic acid resin and long-chain branching, which is applied in the field of long-chain branched polylactic acid resin and its preparation, can solve problems such as high cost, poor blow molding performance, and complicated operation, and achieve high crystallinity and crystallization speed, Effect of increasing melt strength and increasing crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] A preparation method of long-chain branched polylactic acid resin, the preparation process of the polylactic acid resin whose coupling segment is the structure of formula 3 is as follows:

[0056] Step 1: Lactide undergoes ring-opening polymerization under the action of an initiator and a catalyst to obtain multi-arm polylactic acid; the initiator is a polyhydric alcohol, and the catalyst is stannous octoate, diethylzinc, tributylaluminum or bismuth (N,N-bis(trimethylsilyl)amino)zinc, the molar ratio of initiator alcoholic hydroxyl group to lactide is 1:50 to 1:100; the molar ratio of catalyst to lactide is 1:100 to 1 : 1000;

[0057] Step 2: Coupling multi-arm polylactic acid with diisocyanate obtained in step 1 to obtain long-chain branched polylactic acid; wherein the molar ratio of isocyanate groups to terminal hydroxyl groups of multi-arm polylactic acid is 0.8-1.5:1.

[0058] A preparation method of long-chain branched polylactic acid resin, the preparation proce...

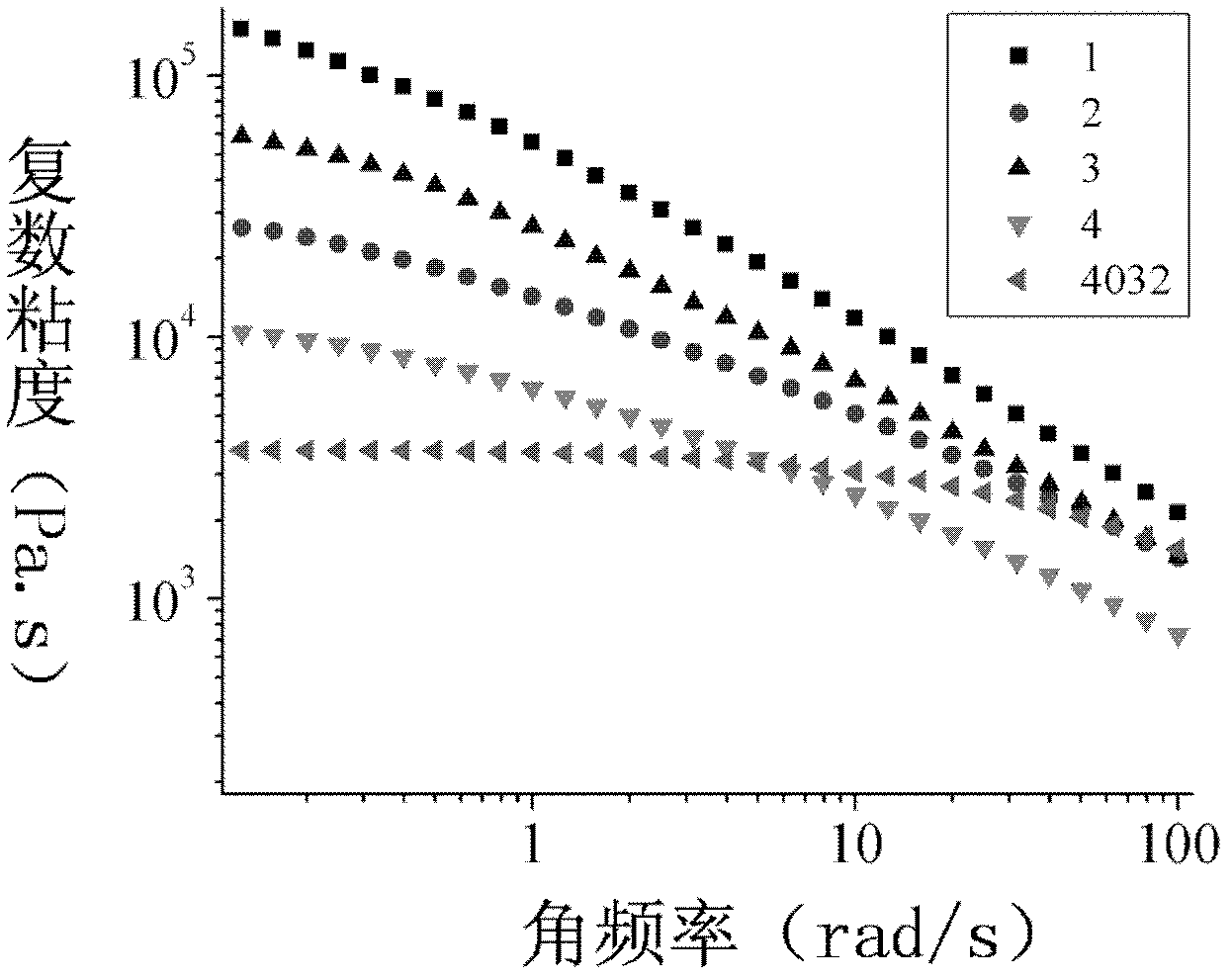

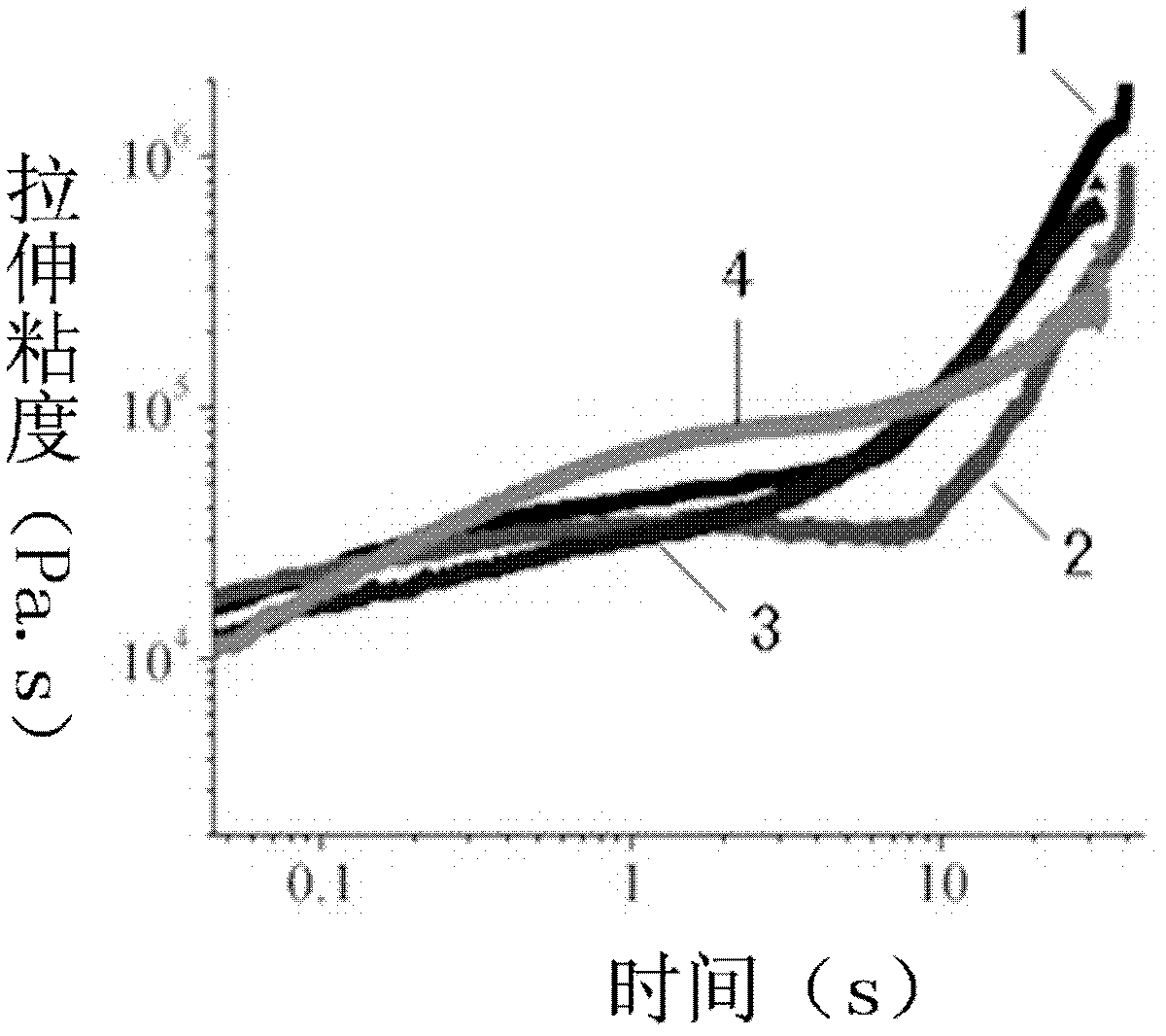

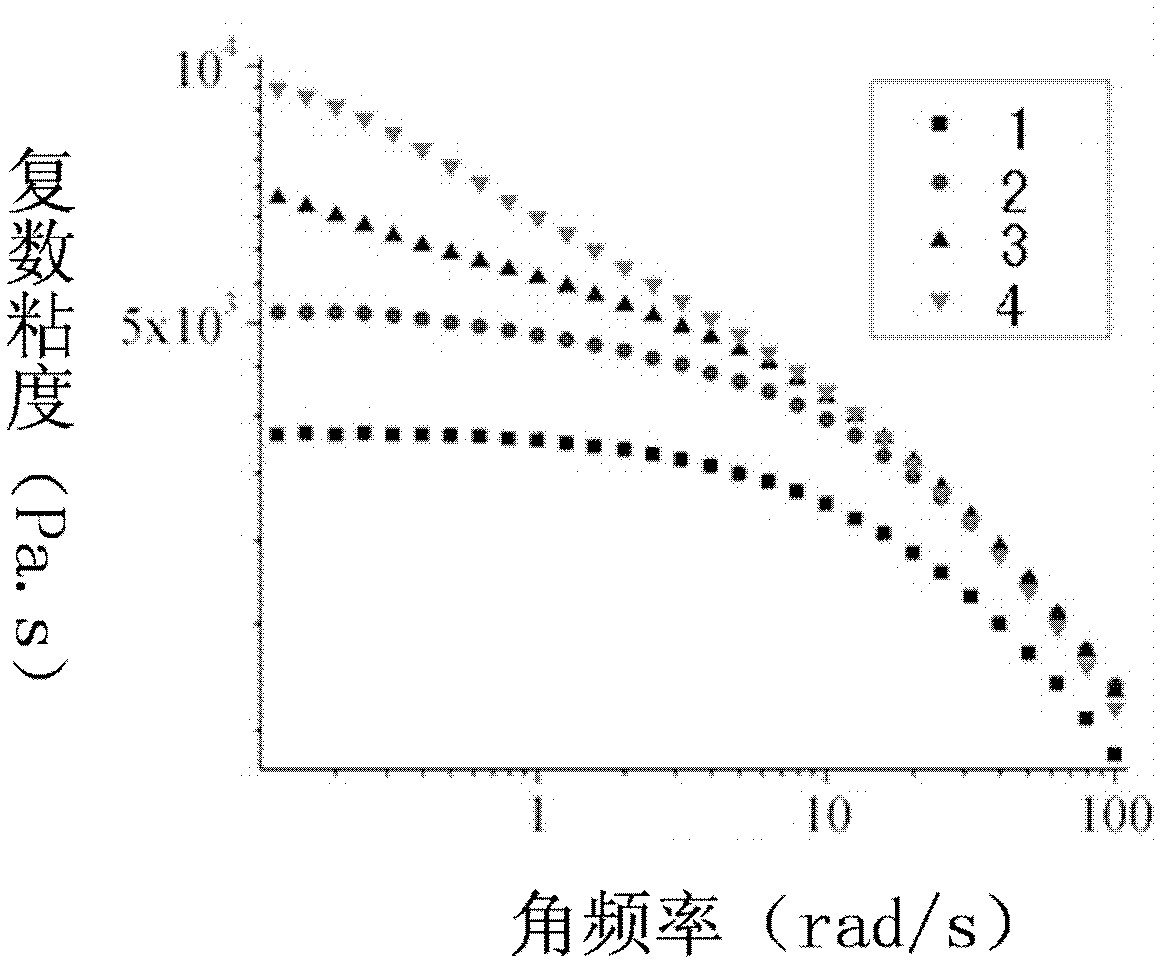

Embodiment 1

[0086] Example 1: 3-Hydroxy Initiated-DP73-HDI Coupling

[0087] Under the protection of nitrogen, 1,1,1-trimethylolpropane (0.1789g, 4mmol OH), lactide (43.2g, 300mmol) were added to the flame-dried reaction flask, and the pumping-gassing was repeated three times , add 140ml of toluene and stannous octoate / toluene solution (3ml, 0.1mmol / ml), and react in an oil bath at 120°C for 24h to obtain three-arm polylactic acid. After the polymerization is completed, adjust the solution temperature to 110°C, under vigorous stirring , add 10ml HDI / toluene solution (0.2mmol / ml), keep at 110°C, stir and react for 0.5 hours, the product is precipitated with cold methanol, and vacuum dried at 60°C for 24h to obtain long-chain branched polylactic acid resin. The polymerization degree of gained long-chain branched polylactic acid resin is 72.5, and productive rate is 95%, and gel content is 0.2%, and absolute molecular weight Mw is 178,000, and polydispersity coefficient is 1.44, and zero-she...

Embodiment 2

[0088] Example 2: 3-Hydroxy Initiated-DP50-MDI Coupling

[0089]Under nitrogen protection, 1,1,1-trimethylolethane (0.160g, 4mmol OH), ethylene glycol (13mg, 0.4mmol), lactide (31.7g, 220mmol LA), were added to the reaction In the still, pump air-inflate repeatedly three times, add stannous octoate / toluene solution (2.2ml, 1.0mmol / ml), heat up to 110°C, stir and polymerize for 2 hours, then heat up to 170°C, continue polymerization for 8 hours, and obtain three-arm A mixture of polylactic acid and linear polylactic acid; after the polymerization is completed, keep the melt temperature at 170°C, under vigorous stirring, add 16.5ml of MDI / toluene solution (0.2mmol / ml) into the reactor, stir for 10 minutes, and the product is cooled Granulate and dry in a vacuum oven at 60°C to obtain long-chain branched polylactic acid resin. The degree of polymerization of the gained long-chain branched polylactic acid resin is 50, the productive rate is 98%, the gel content is 0.3%, the absol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com