Method for extracting baicalin from scutellaria baicalensis

A technology for baicalin and scutellariae, which is applied in the field of extracting baicalin from scutellaria baicalensis, can solve the problems that the content of baicalin cannot meet the requirements of the Pharmacopoeia, the product yield is low, and the energy consumption is large, and achieves stable yield, stable product quality, and high production efficiency. The effect of high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

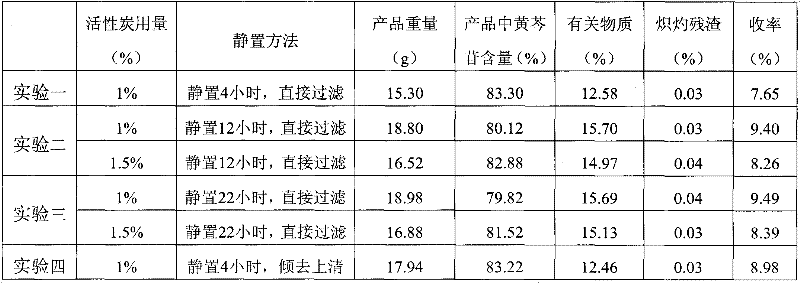

[0078] Scutellaria baicalensis medicinal material 1Kg, pulverized, passed through a No. 1 sieve (2000 microns), extracted with 10 times the amount of water at 90°C for 2 hours for the first time, extracted for 2 hours with 10 times the amount of water at 90°C for the second time, and filtered. Heat the extract to 80°C, adjust the pH to 2.0 with concentrated hydrochloric acid while stirring, keep it warm at 80°C for 1 hour, let it stand for 4 hours, pour off the supernatant, leave the remaining precipitate and a small amount of liquid to stand for 18 hours, filter, wash with water, and dry The crude product was obtained, about 142.5g. Add 12 times the amount of water (1.71Kg) to the crude product to suspend, heat to 80°C, adjust the pH to 7.5 with 20% sodium hydroxide under stirring, then adjust the pH to 6.5 with concentrated hydrochloric acid, add 1.6% activated carbon (27.36g), Heating, stirring, boiling for 0.5 hours, and filtering. The filtrate was heated to 80°C, adjuste...

Embodiment 2

[0082] Scutellaria baicalensis medicinal material 1Kg, pulverized, passed through a No. 1 sieve (2000 microns), extracted with 15 times the amount of water at 80°C for 1.5 hours for the first time, extracted with 8 times the amount of water at 80°C for 1.5 hours for the second time, and filtered. Heat the extract to 80°C, adjust the pH to 1.8 with concentrated hydrochloric acid while stirring, keep it warm at 80°C for 1 hour, let it stand for 4 hours, pour off the supernatant, leave the remaining precipitate and a small amount of liquid to stand for 12 hours, filter, wash with water, and dry The crude product was obtained, about 142.5g. Add 15 times the amount of water (2.14Kg) to the crude product to suspend, heat to 80°C, adjust the pH to 7.0 with 20% sodium hydroxide under stirring, then adjust the pH to 6.3 with concentrated hydrochloric acid, add 1.0% activated carbon (21.40g), Heating, stirring, boiling for 0.5 hours, and filtering. The filtrate was heated to 80°C, adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com