1100KV rod post porcelain insulator

A pillar porcelain insulator and rod-shaped technology, which is applied in the field of electric porcelain, can solve the problems that it is difficult to meet the high-strength requirements of 1100KV rod-shaped pillar porcelain insulators, and the low strength of high-alumina electric porcelain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

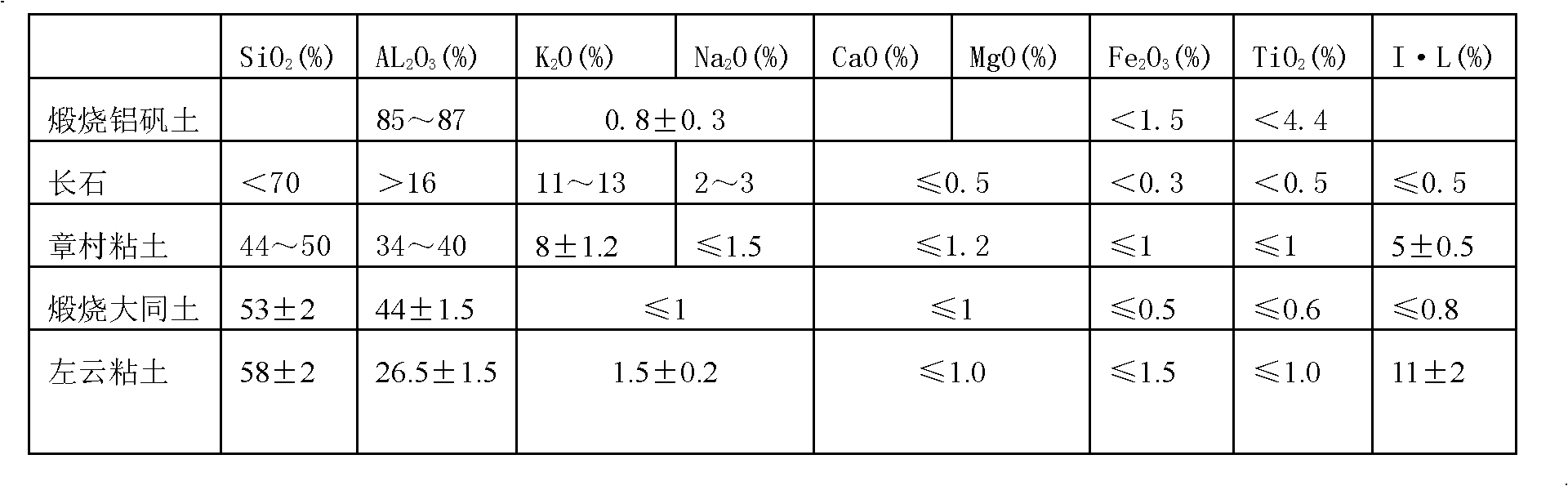

[0014] The 1100KV rod-shaped pillar porcelain insulator of the present invention is prepared by batching, grinding, dry molding and firing. The weight percentage of the batching is: 45% of calcined bauxite, 13% of feldspar, and 12% of Zhangcun clay , calcined Datong soil 13%, Zuoyun clay 17%.

[0015] The test strip strength is 238MPa.

Embodiment 2

[0017] The 1100KV rod-shaped pillar porcelain insulator of the present invention is prepared by batching, grinding, dry molding and firing. The weight percentage of the batching is: 50% of calcined bauxite, 13% of feldspar, and 9% of Zhangcun clay , calcined Datong soil 12%, Zuoyun clay 16%.

[0018] The test strip strength is 235MPa.

Embodiment 3

[0020] The 1100KV rod-shaped pillar electric porcelain insulator of the present invention is prepared by batching, grinding, dry molding and firing. The weight percentage of the batching is: 46% of calcined bauxite, 12% of feldspar, and 10% of Zhangcun clay , calcined Datong soil 12%, Zuoyun clay 20%.

[0021] The test strip strength is 232MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com