Device and method for quickly granulating aerobic activated sludge in membrane bioreactor

A membrane bioreactor and sludge granulation technology, which is applied in chemical instruments and methods, biological water/sewage treatment, sustainable biological treatment, etc., can solve the problem of long sludge granulation process and difficulty in maintaining high performance of membrane bioreactor and other problems to achieve the effect of eliminating membrane fouling, shortening processing time, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

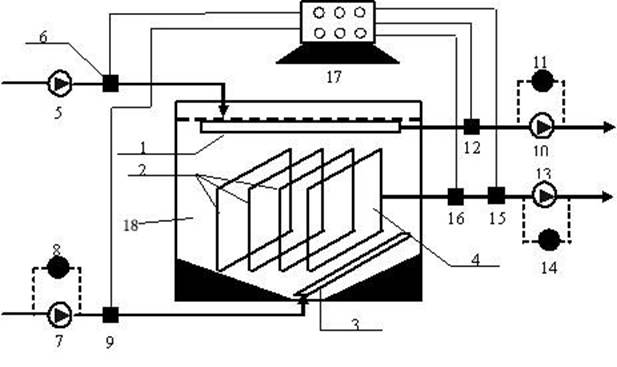

[0026]The aerobic activated sludge was pre-acclimated in the sequencing batch tubular reactor SBR for 2 days, and then the activated sludge solution was quickly transferred to the membrane bioreactor through the connecting pipeline, so that the chemical oxygen demand (COD) concentration was Simulated domestic sewage with 350 mg / L, ammonia nitrogen concentration of 18 mg / L, and pH of 6.86 continuously enters the membrane bioreactor; the following settings are used: the membrane filter outlet pump (13) operates intermittently, pumping for 10 minutes and stopping for 8 minutes The aeration pump (7) stops for 8 minutes after aeration for 172 minutes; the supernatant drainage pump (10) stops for 177 minutes and runs for 3 minutes to perform intermittent operations of membrane filtration, aeration and supernatant discharge. After the membrane bioreactor has been in operation for 14 days, the aerobic activated sludge in it is granulated to form aerobic activated sludge particles, and ...

Embodiment 2

[0029] The aerobic activated sludge was pre-acclimated in the sequencing batch tubular reactor SBR for 5 days, and then the activated sludge solution was quickly transferred to the membrane bioreactor through the connecting pipeline, so that the chemical oxygen demand (COD) concentration was The simulated domestic sewage with 525 mg / L, ammonia nitrogen concentration of 26 mg / L, and pH of 7.0 continuously enters the membrane bioreactor; through the following settings: the membrane filter outlet pump (13) operates intermittently, pumping for 10 minutes and stopping for 8 minutes; After the aeration pump (7) is aerated for 150 minutes, stop for 5 minutes; the supernatant liquid drainage pump (10) stops for 130 minutes and runs for 4 minutes to perform intermittent operations of membrane filtration, aeration and supernatant discharge. After the membrane bioreactor has been in operation for 11 days, the aerobic activated sludge in it is granulated to form aerobic activated sludge pa...

Embodiment 3

[0032] The aerobic activated sludge was pre-acclimated in the sequencing batch tubular reactor SBR for 7 days, and then the activated sludge solution was quickly transferred to the membrane bioreactor through the connecting pipeline, so that the chemical oxygen demand (COD) concentration was Simulated domestic sewage with 478 mg / L, ammonia nitrogen concentration of 61 mg / L, and pH of 7.1 continuously enters the membrane bioreactor; through the following settings: the membrane filter outlet pump 13 operates intermittently, pumping for 6 minutes and stopping for 6 minutes; aeration After pump 7 is aerated for 100 minutes, stop for 5 minutes; supernatant drainage pump 10 stops for 60 minutes, and then runs for 3 minutes to carry out intermittent operation of membrane filtration, aeration and supernatant discharge. After the membrane bioreactor has been in operation for 9 days, the aerobic activated sludge in it is granulated to form aerobic activated sludge particles, and the memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com