Two-effect scale-preventing evaporating and crystallizing device used for evaporating sodium chloride solution and operation method

A sodium chloride solution, evaporative crystallization technology, applied in the direction of alkali metal chlorides, reagents, educts, etc., can solve the problems of difficult operation control, particle material liquid corrosion, and wide application range, so as to achieve smooth feeding and prevent Fouling phenomenon, the effect of realizing continuous and automatic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

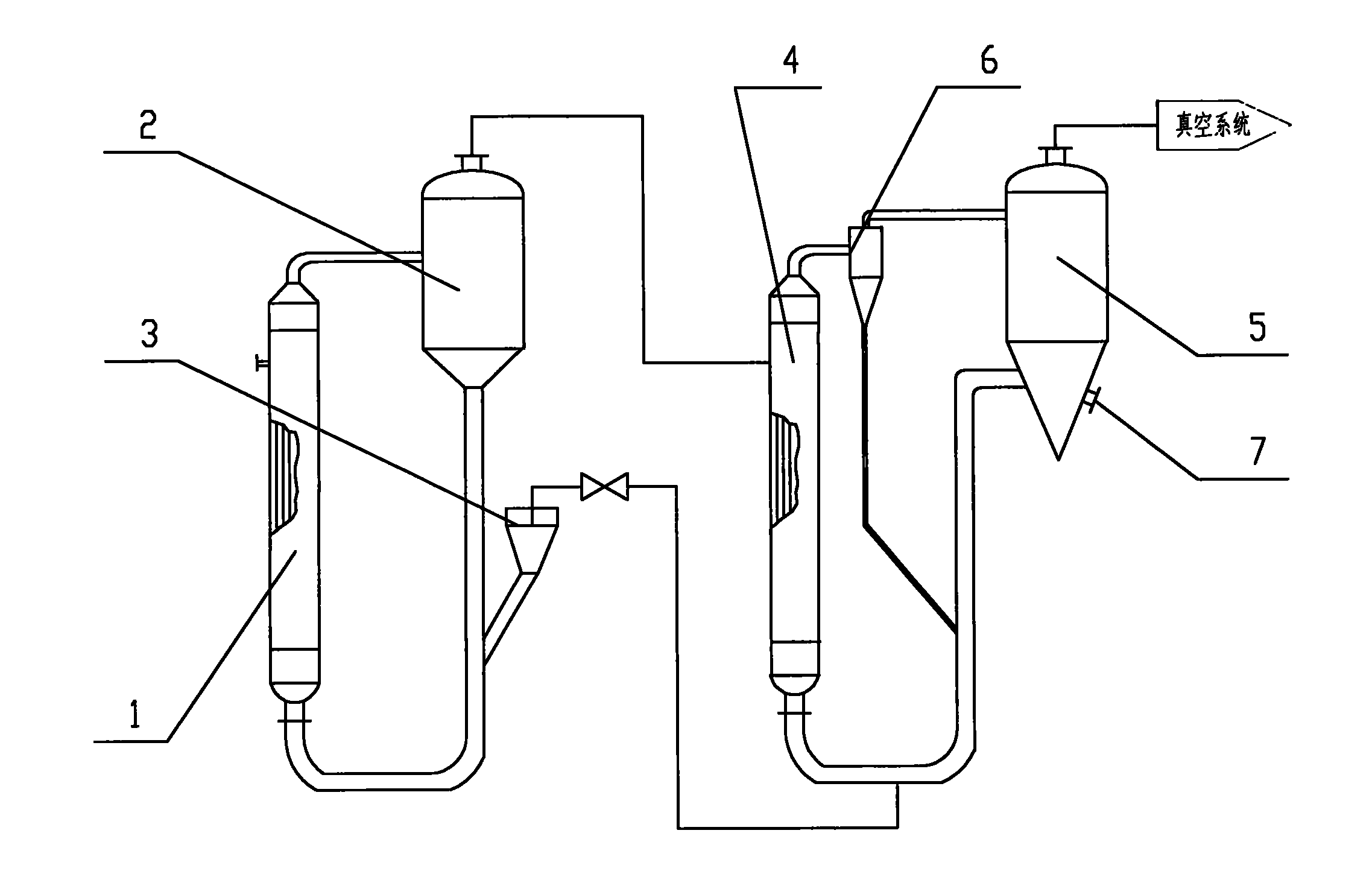

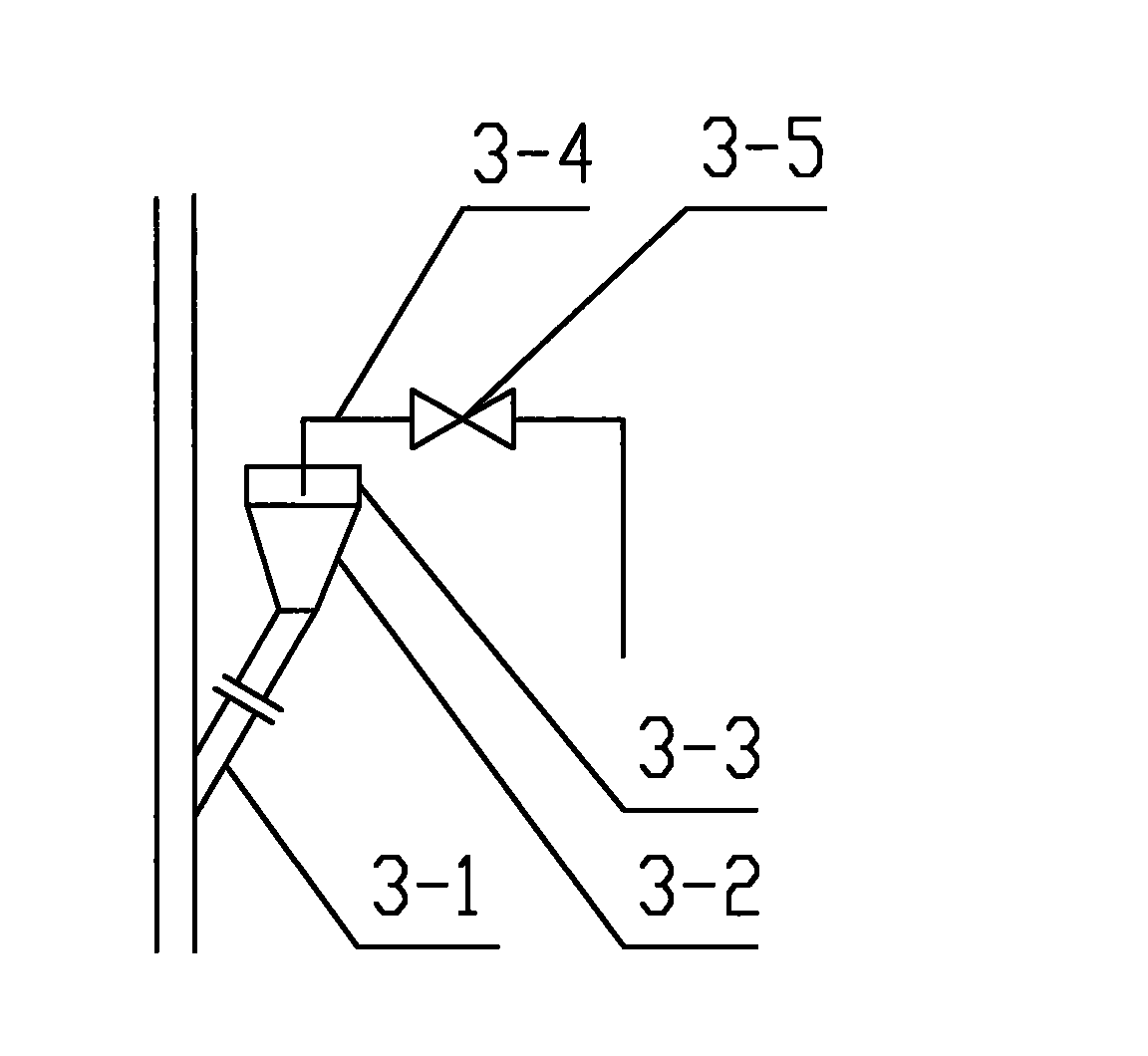

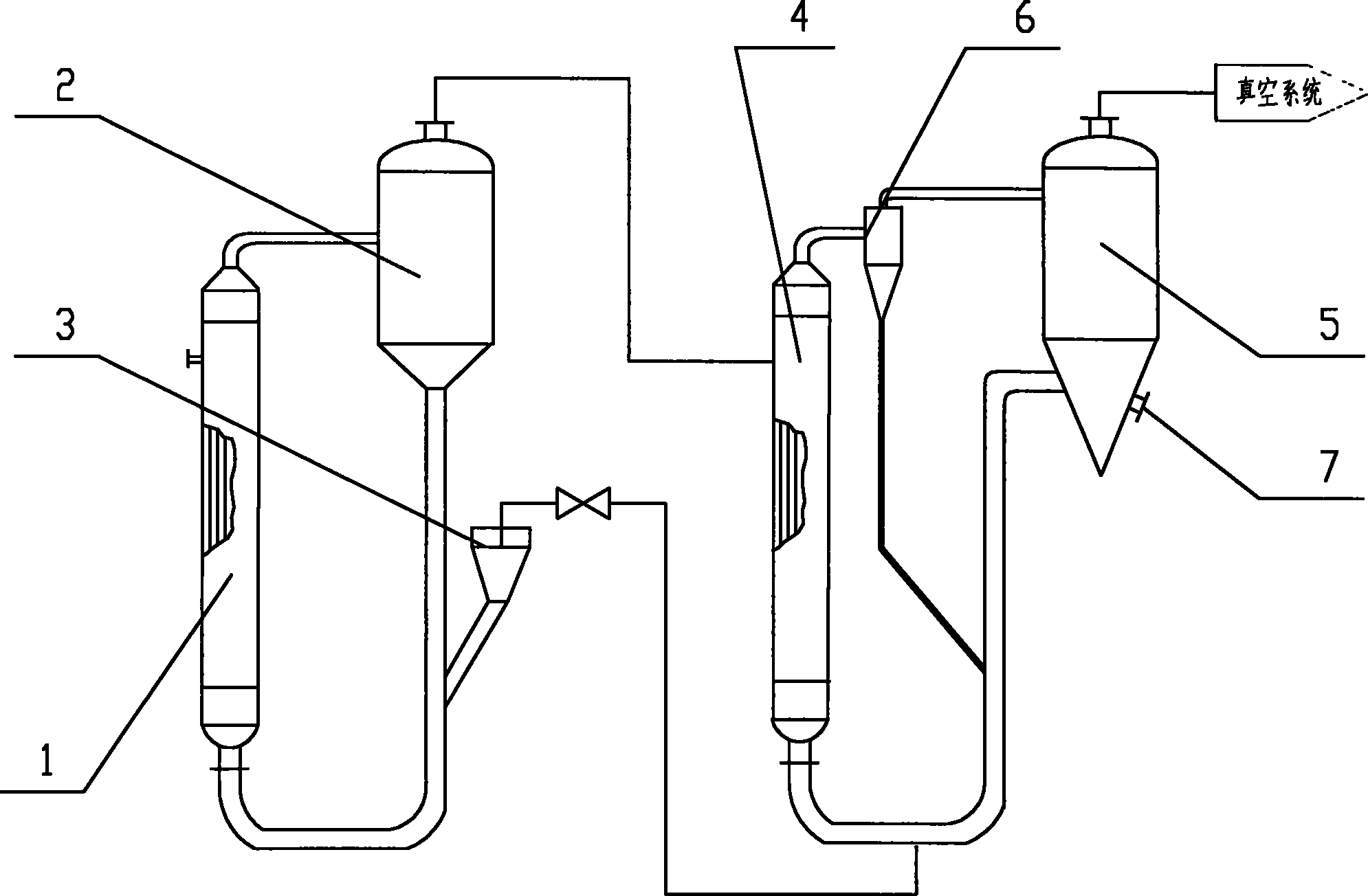

[0021] The two-effect evaporation crystallization device and operation method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] The solid particles that need to be added are injected into the first effect evaporator and the second effect evaporation crystallizer respectively according to the calculated addition amount, the sodium chloride solution to be evaporated enters the first effect evaporator, open the feeding valve between the effects, and close the outlet Material valve 7, open the vacuum system, so that the vacuum degree of the second effect evaporation crystallizer is maintained at 0.065 ~ 0.09MPa. Introduce raw steam into the first effect heating chamber 1, and maintain the pressure at 0.2-0.35MPa.

[0023] In the case of steam heating, firstly, the sodium chloride solution in the first effect heating chamber 1 forms a natural circulation by relying on the density difference generated after heating, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com